High-iron sulfoaluminate cement clinker and preparation method of same

A high-iron sulfoaluminate and cement clinker technology, applied in cement production and other directions, can solve the problems of uneven quality of sulfoaluminate cement, ununiform production and operation parameters, influence of early strength of sulfate cement, etc. Utilization rate, wide source of raw materials, effect of reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

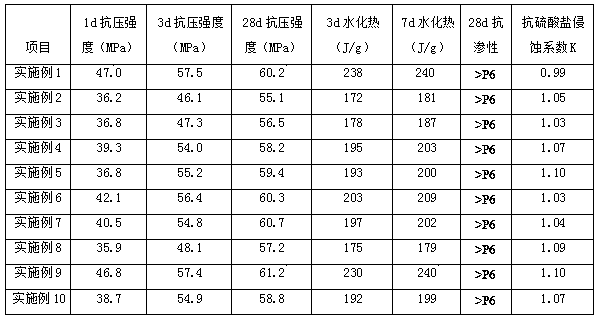

Examples

Embodiment 1

[0021] This embodiment proposes a high iron sulfoaluminate cement clinker.

[0022] The cement clinker is composed of the following raw materials in mass percentage: 70% of calcium material, 5% of aluminum material, 10% of iron material, and 15% of gypsum material.

[0023] The preparation method of cement clinker is as follows: after crushing and grinding the aforementioned raw materials, they are mixed, and then the mixed raw meal is calcined at 1100° C. for 90 minutes, and the cement clinker is obtained after cooling. The mineral composition of the cement clinker is C 4 A 3 S: 55%, C 2 S: 20%, C 4 AF: 15%, Others: 10%.

Embodiment 2

[0025] This embodiment proposes a high iron sulfoaluminate cement clinker.

[0026] The cement clinker is composed of the following raw materials in mass percentage: 45% of calcium material, 40% of aluminum material, 10% of iron material, and 5% of gypsum material.

[0027] The preparation method of cement clinker is as follows: after crushing and grinding the aforementioned raw materials, they are mixed, and then the mixed raw meal is calcined at 1245° C. for 30 minutes, and the cement clinker is obtained after cooling. The mineral composition of the cement clinker is C 4 A 3 S: 35%, C 2 S: 30%, C 4 AF: 25%, Others: 10%.

Embodiment 3

[0029] This embodiment proposes a high iron sulfoaluminate cement clinker.

[0030] The cement clinker is composed of the following raw materials in mass percentage: 51% limestone, 17% low-grade bauxite, 24% high-iron bauxite, and 8% desulfurized gypsum.

[0031] The preparation method of cement clinker is as follows: after crushing and grinding the aforementioned raw materials, they are mixed, and then the mixed raw meal is calcined at 1200°C for 30 minutes, and the cement clinker is obtained after cooling. The mineral composition of the cement clinker is C 4 A 3 S: 36%, C 2 S: 33%, C 4 AF: 23%, Other: 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com