A novel fabrication method of interconnected silicon through hole with adjustable resistance

A manufacturing method and technology for interconnecting silicon, applied in separation methods, chemical instruments and methods, components of TV systems, etc., can solve problems such as heavy weight, large volume, and difficulty in integration, avoiding the need for process equipment and reducing resistance The effect of matching difficulty and avoiding stress concentration problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

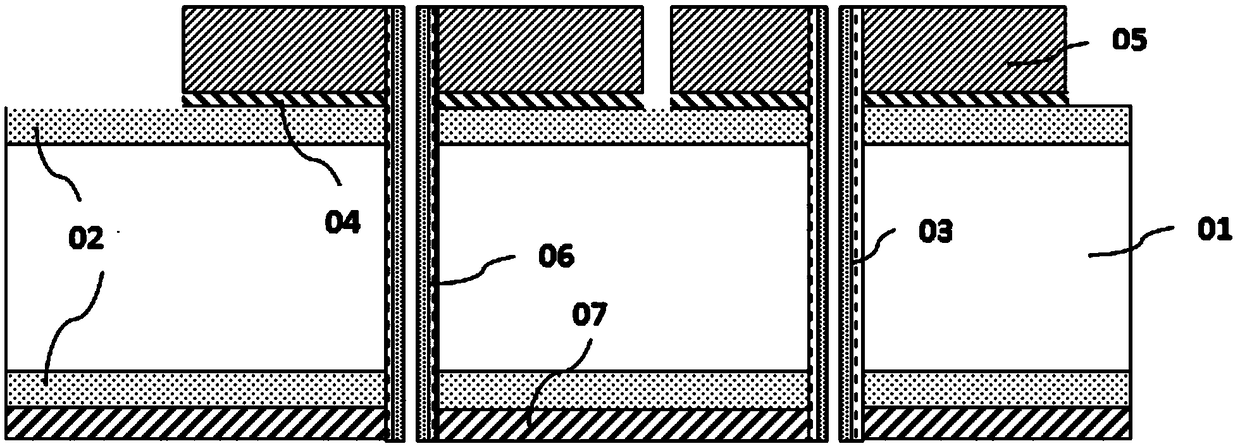

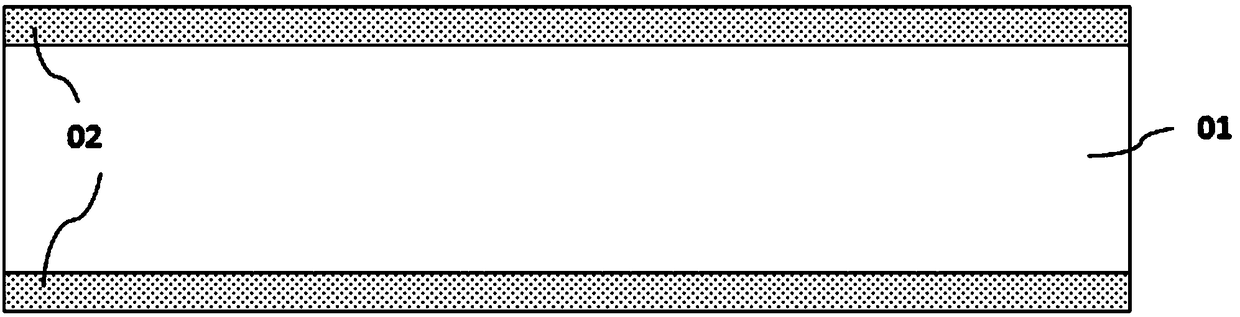

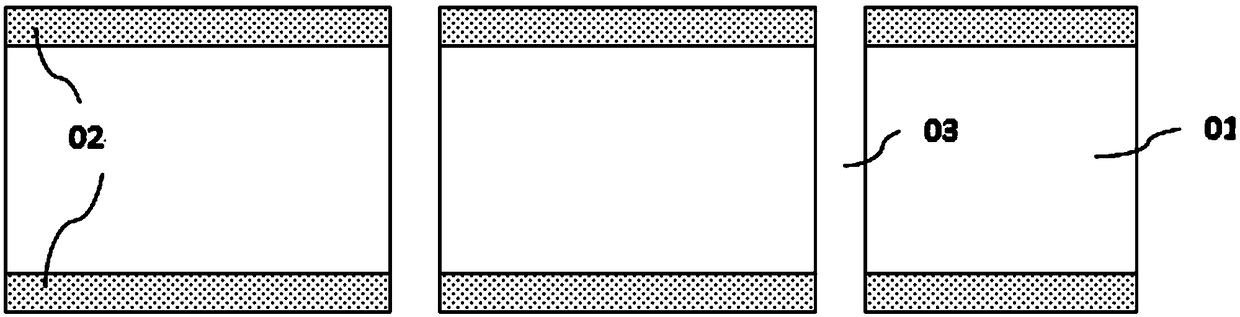

[0037] The invention relates to a new manufacturing method of interconnected through-silicon vias with adjustable resistance, which uses a silicon substrate to realize the manufacture of through-hole interconnections, and uses an electroplating process to control the resistance value of the through-hole resistance; figure 1 Shown is a side view of TSV interconnection. It can be seen from the figure that the interconnection of TSV is realized by using MEMS technology, including deep silicon etching process, metal film deposition process, thick resist photolithography process, and thick metal layer electroplating process. This via has significant resistive properties that can be used to compensate for the resistive properties of the devices it interconnects.

[0038] A novel manufacturing method of interconnected through-silicon vias with adjustab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com