Continuous fiber reinforced composite material 3D printer sprayer device of integrated structure

A technology of reinforced composite materials and 3D printers, which is applied in coating devices, additive processing, 3D object support structures, etc., and can solve the problem of large printing nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

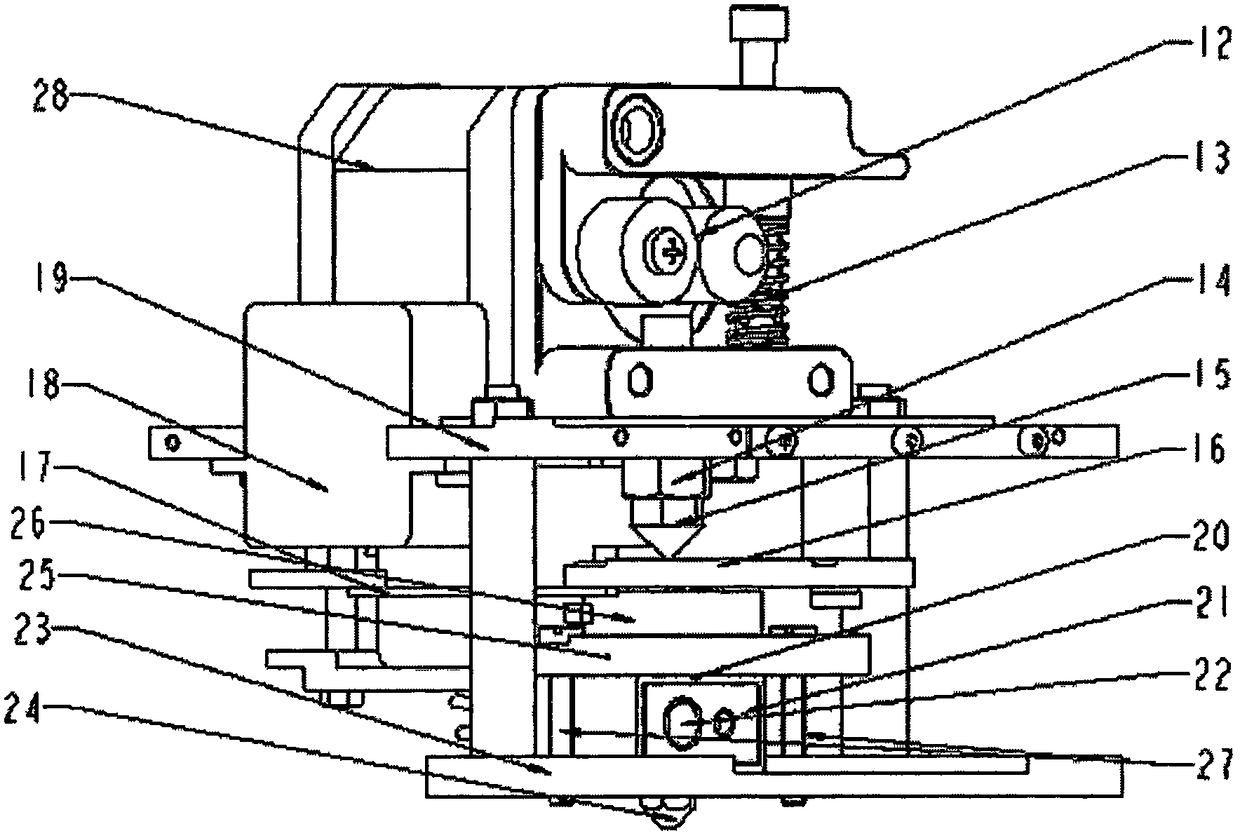

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] The invention belongs to a continuous fiber reinforced composite material 3D printer nozzle device with an integrated structure. The nozzle device is a composite material 3D printer nozzle device integrating a matrix / support material printing nozzle device and a fiber material printing nozzle device; the fiber material printing nozzle device is A fiber material printing device that integrates feeding, melting, clamping and cutting; it has a heat dissipation device.

[0010] The substrate / support material nozzle printing device 1 and the fiber material printing nozzle device 2 are assembled into one body through the central positioning plate 19 and the heating block positioning plate 23 by the connecting bolt 42 of the central positioning plate and the heating block positioning plate. The substrate / support material printing nozzle device 1 is ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com