Mobile Hole Saw Fixing Bracket

A technology for fixing brackets and hole saws, which is applied in the direction of large-scale fixed members, supports, clamping, etc., and can solve problems such as high safety risk factor, labor-intensive, and slow opening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

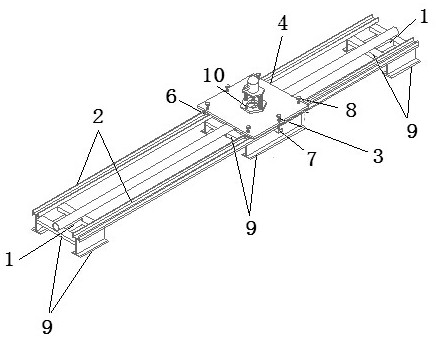

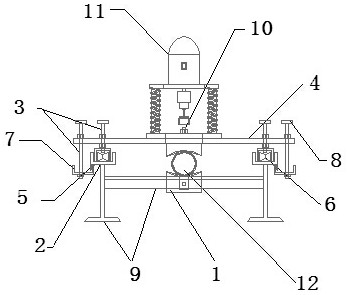

[0022] see figure 1 , figure 2 It can be seen that the mobile hole opener fixed bracket of the present invention, the hole opener fixed bracket body is provided with a fixed structure and a mobile structure, the fixed structure is a fixed bracket 9, and the fixed bracket 9 includes a vertical fixed frame and a horizontal fixed frame, and the horizontal fixed frame The middle part of the fixed frame is provided with a pipe clamp 1, the mobile structure is a supporting platform, the upper part of the supporting platform is provided with a fixing device, and the lower part of the supporting platform is provided with a sliding structure, and the sliding structure is a sliding wheel 6, which is arranged in the groove In the steel slideway 2, height adjustment devices are arranged on both sides of the supporting platform, the supporting platform is a steel plate 4, the size of the steel plate 4 is 15mm thick, the horizontal fixing frame is a horizontal channel steel, and the bottom...

specific Embodiment 2

[0024] see figure 1 , figure 2 It can be seen that the structure of the present invention consists of two parts, which are divided into a fixed structure and a mobile structure of the bracket. The fixed structure uses 8# channel steel to be welded into a fixed bracket 9 with a support system, the bottom part of the pipe clamp 1 is fixed at the middle position of the horizontal channel steel of the fixed bracket, and a channel steel slideway 2 is welded on the top of the fixed structure support; The structure uses a steel plate 4 with a thickness of 15 mm. The size of the steel plate 4 is determined according to the size of the hole opener 11. The steel plate 4 fixes the hole opener 11 through fixing bolts 10, and four slides are respectively installed on the four corners of the steel plate 4. The wheel 6 is placed on the channel steel slideway 2, the sliding wheel 6 and the steel plate 4 are connected by a height-adjustable screw rod 3, and the top part of the pipe clamp 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com