A detection method for penetration depth and fusion width of welding surface of thin-walled materials

A detection method and welding surface technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of not being able to truly and accurately reflect the welding quality of the weld seam of materials, and achieve the effect of simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

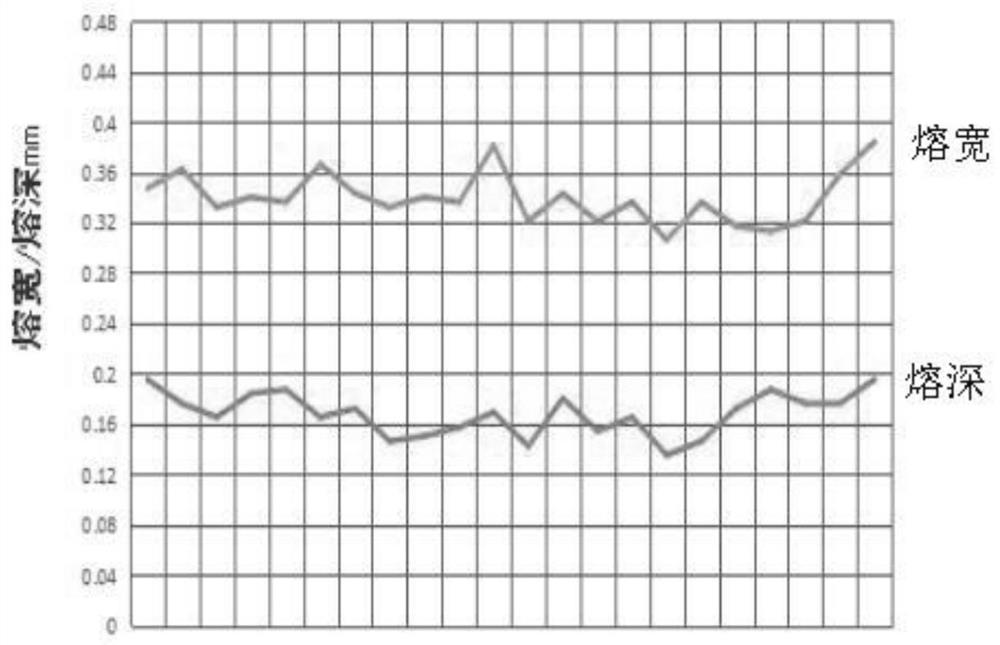

[0053]This embodiment provides a method for detecting the penetration depth and penetration width of the welding surface of a thin-walled material. The thin-walled material is a tube shell of an igniter for an airbag and a seatbelt gas generator. The igniter for the igniter is installed in the closed explosive device and detonated under the condition of 1.2A constant current DC. The residual shell of the igniter is selected, and the specific implementation is as follows:

[0054]Step 1. Cut the remaining tube shell to be tested, and clean the cut surface after cutting to obtain the tube shell fragment

[0055]Step 1.1. Put the residual shell of the tube to be tested into the cutting machine mold, load 5 pieces at a time, switch the cutting machine operation and water adding mode to automatic, and run the cutting machine;

[0056]Step 1.2. After cutting by the cutting machine, the primary tube shell fragment is obtained, and the primary tube shell fragment is taken out with tweezers;

[0057]Ste...

Embodiment 2

[0075]This embodiment provides a method for detecting the penetration depth and penetration width of the welding surface of a thin-walled material. The thin-walled material is a tube shell of an igniter for an airbag and a seatbelt gas generator. The igniter for the igniter is installed in the closed explosive device, and it is detonated under the condition of 1.19A constant current DC. The residual shell of the igniter is selected, and the specific implementation is as follows:

[0076]Step 1. Cut the remaining tube shell to be tested, and clean the cut surface after cutting to obtain the tube shell fragment

[0077]Step 1.1. Put the residual shell of the tube to be tested into the cutting machine mold, one piece at a time, switch the cutting machine operation and water adding mode to automatic, and run the cutting machine;

[0078]Step 1.2. After cutting by the cutting machine, the primary tube shell fragment is obtained, and the primary tube shell fragment is taken out with tweezers;

[0079...

Embodiment 3

[0096]This embodiment provides a method for detecting the penetration depth and penetration width of the welding surface of a thin-walled material. The thin-walled material is a tube shell of an airbag and a seatbelt gas generator igniter, which generates gas from the airbag and the seatbelt. The igniter for the igniter is installed in the closed explosive device, and it is detonated under the condition of 1.21A constant current DC. The residual shell of the igniter is selected, and the specific implementation is as follows:

[0097]Step 1. Cut the remaining tube shell to be tested, and clean the cut surface after cutting to obtain the tube shell fragment

[0098]Step 1.1. Put the residual shell of the tube to be tested into the cutting machine mold, 4 pieces at a time, switch the cutting machine operation and water adding mode to automatic, and run the cutting machine;

[0099]Step 1.2. After cutting by the cutting machine, the primary tube shell fragment is obtained, and the primary tube s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com