Pouring ladle beneficial to slag blocking

A technology of pouring ladle and slag baffle plate, which is applied to casting melt containers, metal processing equipment, casting equipment, etc., can solve the problems affecting the quality, shape and structure of castings, affecting the temperature and purity of molten iron, and achieve the same pouring rate, Conducive to the material blocking effect and the effect of improving the liquid level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

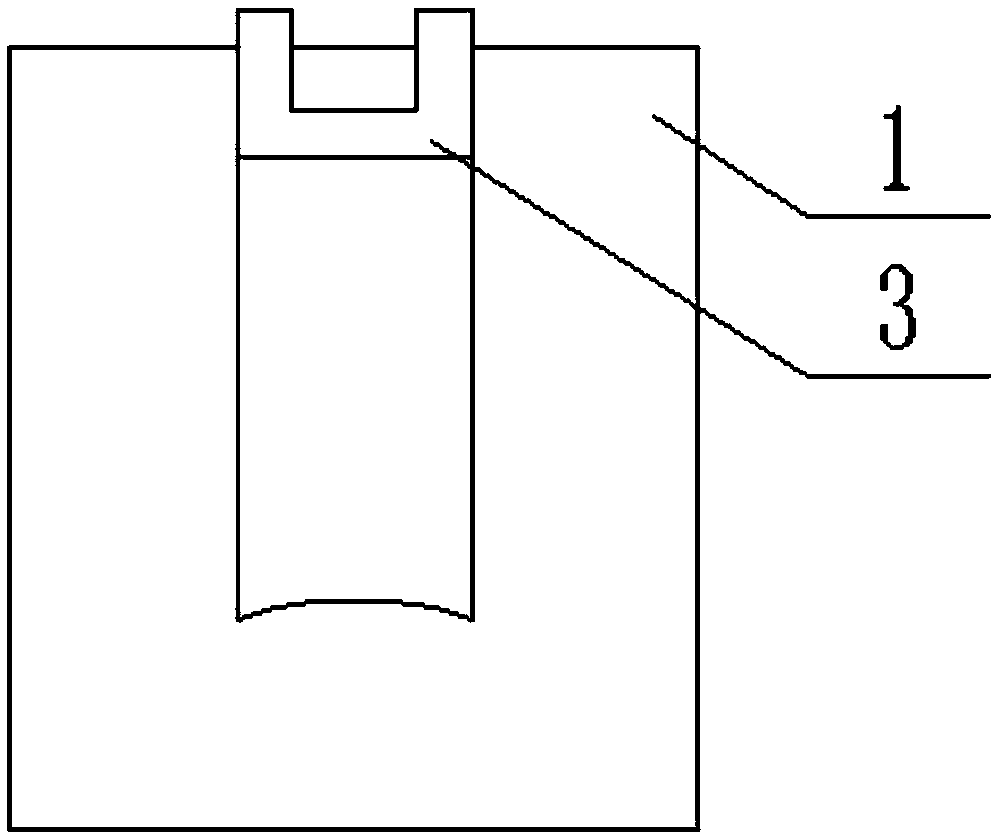

[0021] Such as Figure 1 to Figure 4 As shown, it is a casting ladle that is beneficial to slag blocking proposed by the present invention, including a pouring cylinder 1, a slag blocking plate 2, a spout 3, a pouring groove 4 and a water outlet 6;

[0022] The pouring tank 4 includes a liquid storage tank 401 and a liquid injection tank 402; the pouring cylinder 1 is a hollow cylindrical structure, and the liquid storage tank 401 is arranged in the pouring cylinder 1; the ratio of the bottom diameter of the liquid storage tank 401 to the height of the pouring cylinder 1 is 1:2 ;

[0023] The spout 3 is fixedly installed on the pouring cylinder 1, the liquid injection tank 402 is set in the spout 3; the slag stopper 2 is fixedly installed in the spout 3, and the water outlet 6 is set between the slag stopper 2 and the bottom of the liquid injection tank 402 Between; the liquid injection tank 402 and the liquid storage tank 401 communicate through the water outlet 6 .

[0024...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com