Home miniature sound wave cleaning machine

A sonic cleaning and miniature technology, which is applied in the direction of cleaning methods using liquids, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of low efficiency of acoustic and electric replacement, low cleaning efficiency, inconvenience, etc., and improve the sound insulation effect , Reduce working noise and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

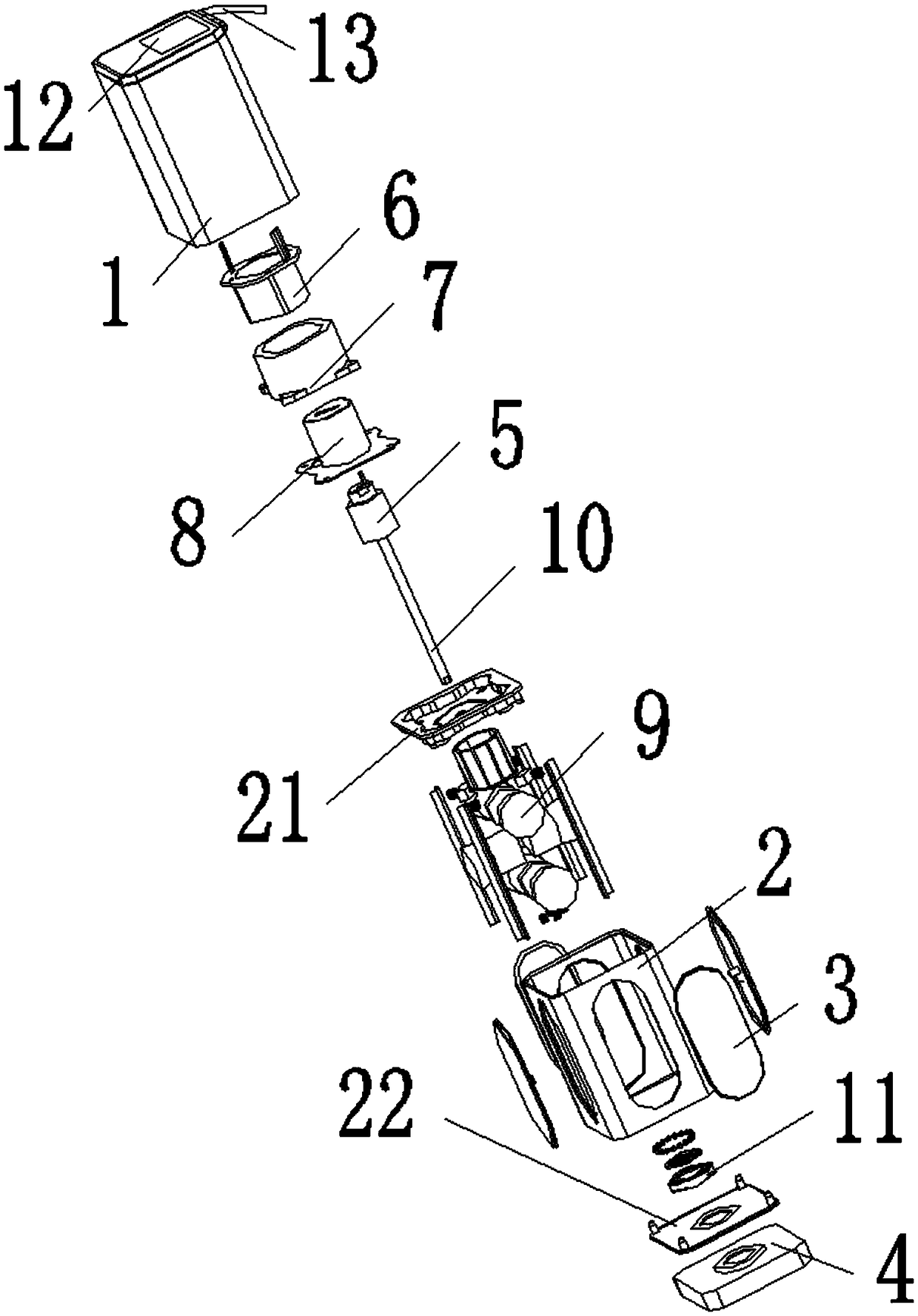

[0032] see Figure 1-7 , the present invention provides the following technical solutions: a household miniature acoustic wave cleaning machine, comprising a base 4, the upper end of the base 4 is placed with a lower casing 2, the side of the lower casing 2 is integrally formed with a steel plate 3, and the inner wall of the steel plate 3 is fixed with an ultrasonic transducer 9, the lower casing 2 also includes the upper end surface 21 of the lower casing and the lower end surface 22 of the lower casing, a waterproof slip ring is arranged above the lower casing 2, and an outer rotor stepping motor is placed inside the waterproof slip ring, and the lower casing An upper housing 1 is placed above the upper housing 1. In this embodiment, the upper housing 1 integrates an ultrasonic generator circuit system, a motor drive circuit, a control circuit, etc., and the upper housing 1 is highly integrated with an ultrasonic generator circuit system and a motor drive circuit. As well as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com