Intelligent ceramic rotary valve

A technology of rotary valves and ceramics, applied in valve details, valve devices, valve housing structures, etc., can solve problems such as pipeline blockage, and achieve the effects of high hardness and wear resistance, strong cleaning force, and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

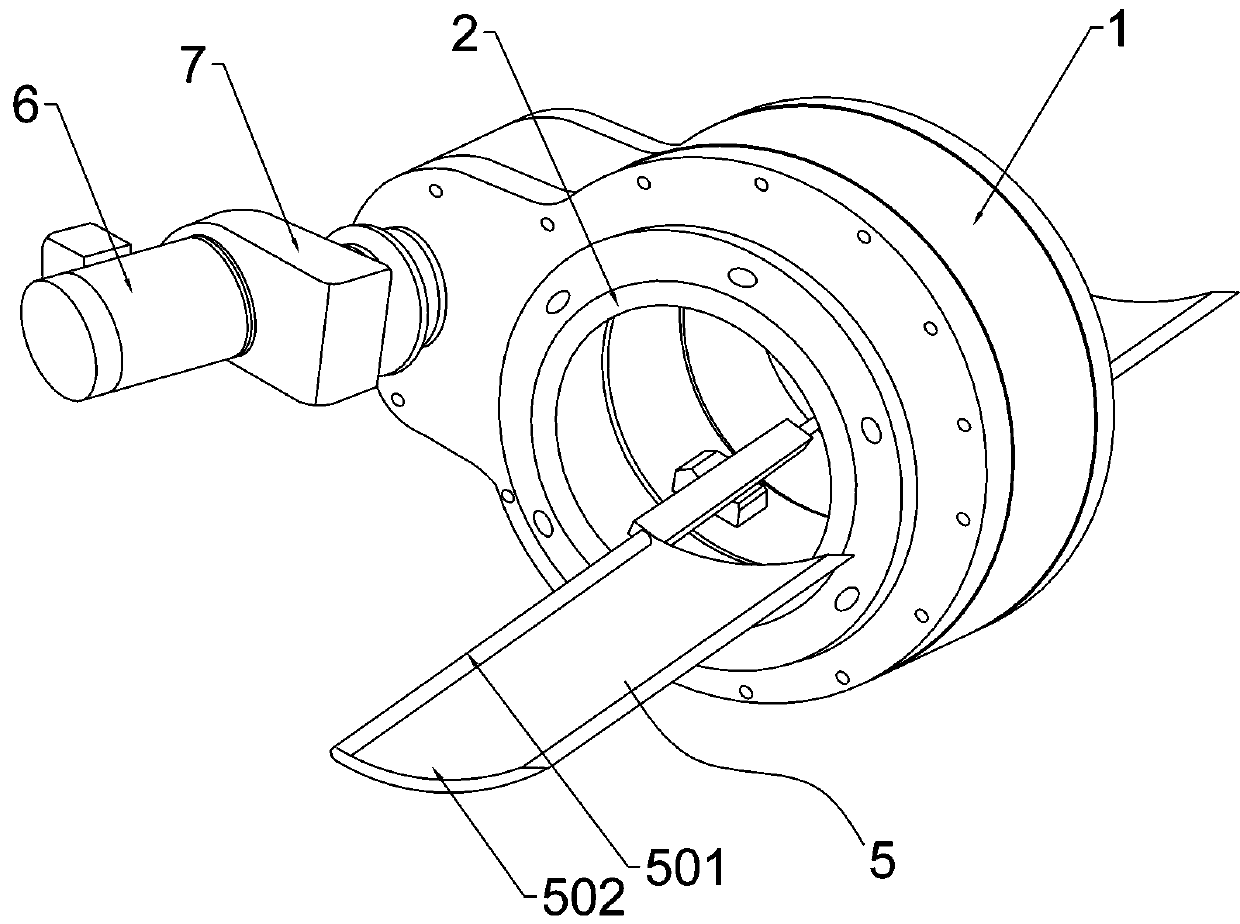

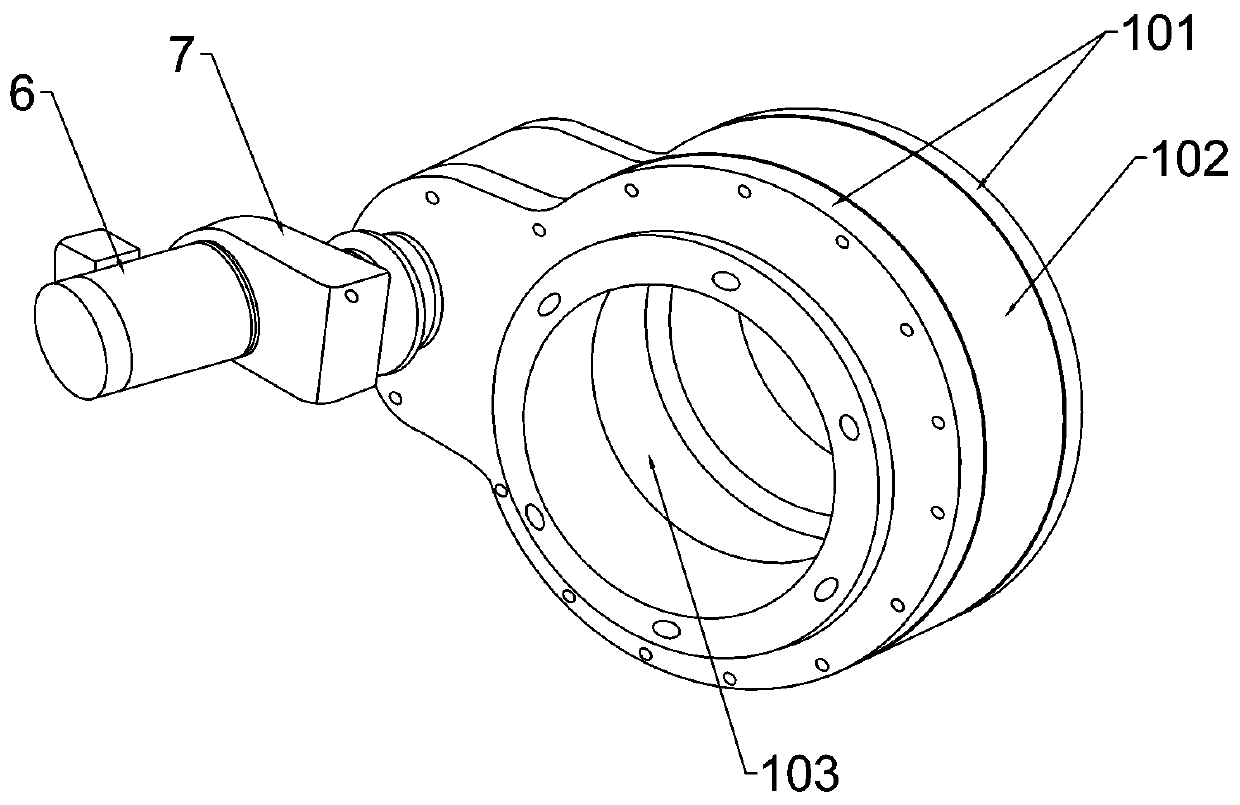

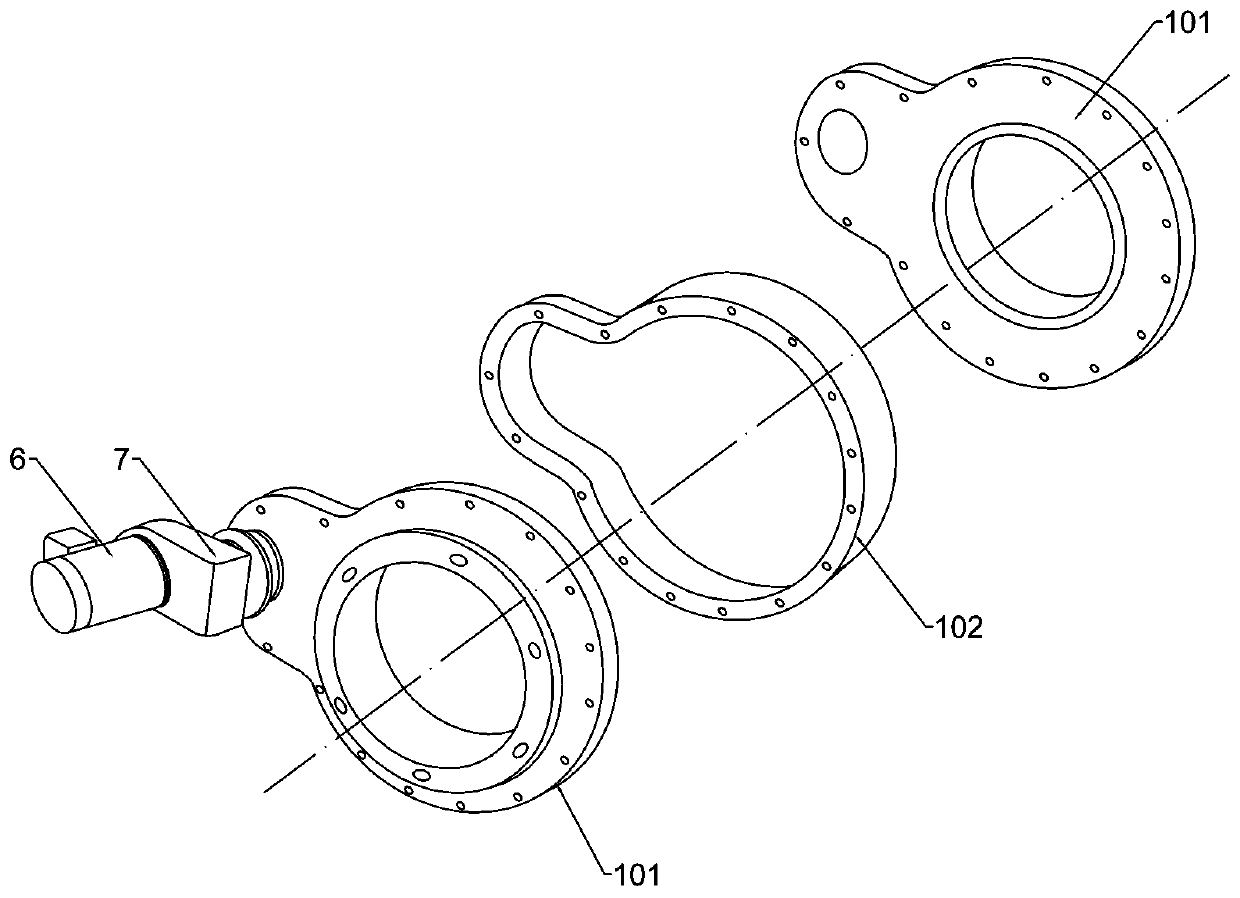

[0034] Example 1: An intelligent ceramic rotary valve, such as Figure 1-10 As shown, the valve body 1 is included. The valve body includes two main casings 101 and an intermediate casing 102. The intermediate casing is located between the two main casings. The outer ends of the two main casings are integrally provided with flange end faces. Used to connect the conveying pipeline 13, the inner ends of the two main shells 101 are respectively symmetrically bolted on both sides of the middle shell 102, so that a valve tube and a valve cavity are formed in the valve body. The central axes are parallel to each other; because the intermediate housing 102 is sandwiched between the two main housings 101, an annular gap 103 can be formed on the wall of the valve tube, and the width of the annular gap is equal to the width of the intermediate housing 102 , The valve tube and the valve cavity are kept in communication with each other through the annular gap 103. The purpose of this desig...

Embodiment 2

[0042] Embodiment 2: An intelligent ceramic rotary valve of this embodiment, and the description is centered on the difference from Embodiment 1.

[0043] When the small-scale transportation pipeline 13 has cost requirements or space constraints, the motor rotation can be replaced by manual rotation, such as Picture 9 As shown, in this embodiment, the power mechanism includes a rotating rod 8 and a manual crank 9. The inner end of the rotating rod 8 is connected to the axle of the power output gear 4, and the manual crank 9 rotates to drive the transmission ring 3 and the rotating bushing 202 rotates, and the worker regularly rotates the manual crank 9 to clean the inner wall of the conveying pipe 13 regularly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com