Polyimide composite membrane for pervaporation treatment of high concentration brine and preparation method thereof

A technology of polyimide and composite membrane, which is applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, seawater treatment, etc., to achieve good chemical stability, improve water flux, and reduce separation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 10.4g of pyromellitic anhydride and 21.3g of phosphorus pentachloride in a flask, and heat, stir and reflux at 160°C for 10h. Distill under reduced pressure at 120°C to remove excess phosphorus pentachloride and phosphorus oxychloride, dissolve and recrystallize in dichloromethane to obtain pure pyromellitic chloride.

[0034] Prepare a sodium hydroxide solution with a concentration of 2 mol / L, and soak the PAN film for 1 hour at a temperature of 60°C.

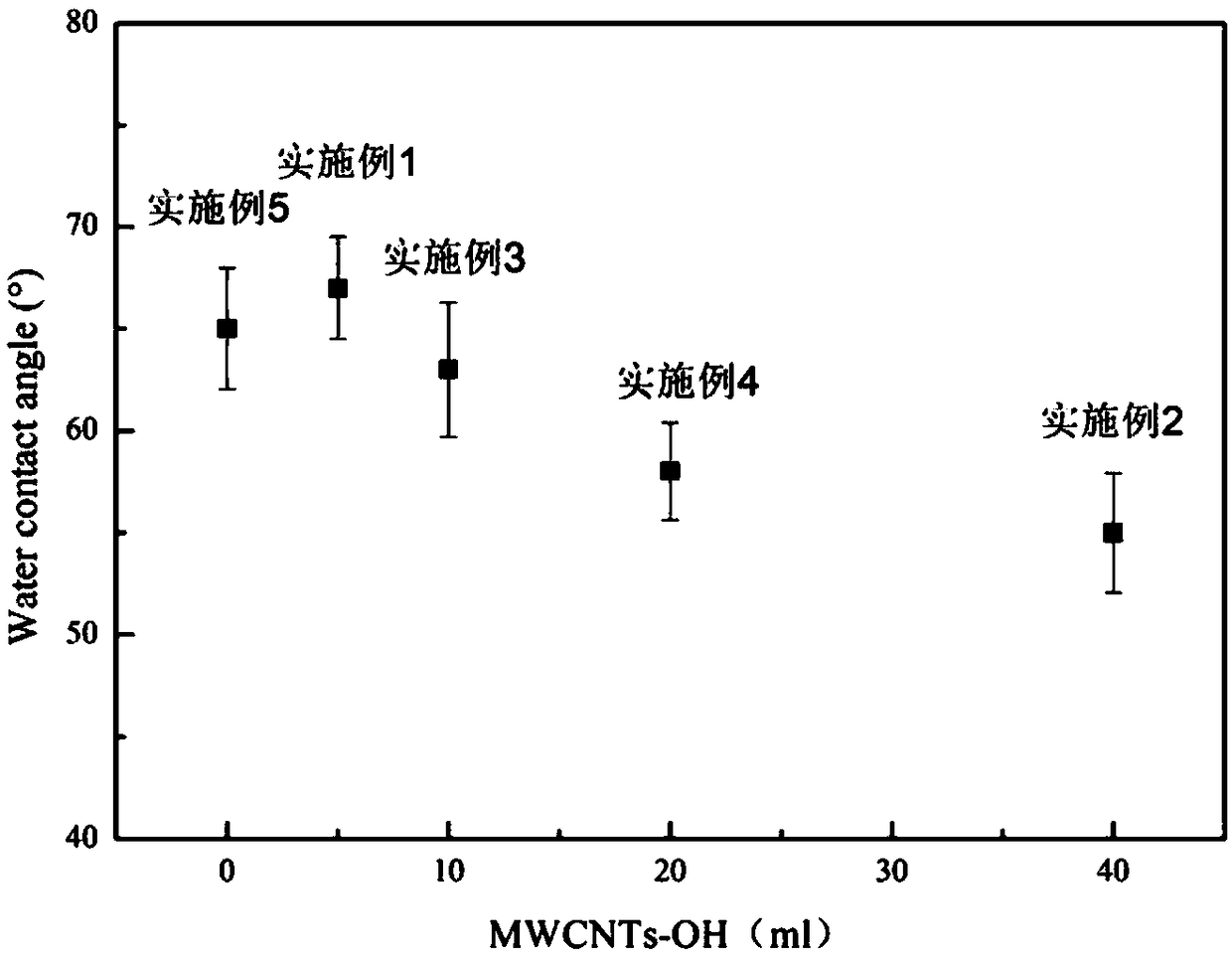

[0035] Place the soaked H-PAN base film in the sand core funnel, pipette 5ml of the prepared and ultrasonically dispersed 0.02g / LMWCNTs-OH / EtOH solution into the sand core funnel, and use a vacuum pump to pump at 0.1MPa. Filter to fill the MWCNTs-OH to the H-PAN bottom membrane.

[0036] Prepare 1wt% m-phenylenediamine aqueous phase solution, add 0.4g sodium lauryl sulfate, 0.1g sodium hydroxide and 0.3g sodium carbonate; prepare 0.05wt% pyromellitic chloride n-hexane organic phase solution. Soak the pretreated ...

Embodiment 2

[0043] Weigh 9.2g of pyromellitic anhydride and 19.8g of phosphorus pentachloride in a flask, and heat, stir and reflux at 160°C for 10h. Distill under reduced pressure at 120°C to remove excess phosphorus pentachloride and phosphorus oxychloride, dissolve and recrystallize in dichloromethane to obtain pure pyromellitic chloride.

[0044] Prepare a sodium hydroxide solution with a concentration of 2 mol / L, and soak the PAN film for 1 hour at a temperature of 60°C.

[0045] Place the soaked H-PAN base film in the sand core funnel, pipette 40ml of the 0.02g / LMWCNTs-OH / EtOH solution prepared and dispersed by ultrasonic waves into the sand core funnel, and use a vacuum pump to pump at 0.1MPa. Filter to fill the MWCNTs-OH to the H-PAN bottom membrane.

[0046] Prepare 2wt% hexamethylenediamine aqueous phase solution, add 0.25g sodium dodecylbenzenesulfonate and 0.3g potassium carbonate to prepare 0.1wt% pyromelliticoyl chloride n-hexane organic phase solution. Soak the pretreated...

Embodiment 3

[0052] Weigh 14.2 g of pyromellitic anhydride and 33.6 g of phosphorus pentachloride in a flask, and heat, stir and reflux at 160° C. for 10 h. Distill under reduced pressure at 110°C to remove excess phosphorus pentachloride and phosphorus oxychloride, dissolve and recrystallize in dichloromethane to obtain pure pyromellitic acid chloride.

[0053] Prepare a sodium hydroxide solution with a concentration of 2 mol / L, and soak the PAN film for 1 hour at a temperature of 60°C.

[0054] Place the soaked H-PAN base film in the sand core funnel, pipette 10ml of the prepared and ultrasonically dispersed 0.02g / LMWCNTs-OH / EtOH solution into the sand core funnel, and pump it with a vacuum pump at 0.1MPa. Filter to fill the MWCNTs-OH into the H-PAN bottom membrane.

[0055] Prepare 3wt% propylenediamine aqueous phase solution, wherein add 0.1g sodium alkylbenzenesulfonate, 0.1g salt of wormwood and 0.15g sodium carbonate, prepare 0.2wt% pyromellitic acid chloride n-hexane organic phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com