Environment-friendly and wear-resistant degradable PVC decorative artificial leather

A technology of artificial leather and PVC resin powder, which is applied in the direction of textiles and papermaking, etc., to achieve the effects of good migration resistance, enhanced migration resistance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

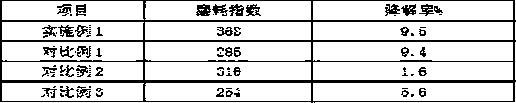

Examples

Embodiment 1

[0025] An environmentally friendly, wear-resistant and degradable PVC decorative artificial leather, made of the following raw materials: 135 parts of PVC resin powder, 14 parts of vinyl acetate resin, 18 parts of diacetyl epoxy glycerin soybean oil, polycaprolactone-based polyurethane elastic 9 parts of body, 1 part of foaming agent, 16 parts of epoxy soybean oil, 25 parts of modified attapulgite, 1.6 parts of lubricant, 1.5 parts of silicone masterbatch, 1 part of stabilizer, 1.2 parts of pigment; Use titanium dioxide or other organic pigments.

[0026] The modified attapulgite is modified by the following steps:

[0027] (1) Crush the attapulgite, pass it through a 60-mesh sieve, soak it in an oxalic acid solution with a mass fraction of 5% for 1-2 hours, and then wash it with clean water until neutral;

[0028] (2) Soak the attapulgite treated in step (1) with 2.5% sodium dodecylbenzenesulfonate, which is 10 times the weight of the attapulgite, for 15-20 minutes, and use ...

Embodiment 2

[0039] An environmentally friendly wear-resistant and degradable PVC decorative artificial leather, made of the following raw materials: 140 parts of PVC resin powder, 15 parts of vinyl acetate resin, 20 parts of diacetyl epoxy glycerin soybean oil, polycaprolactone-based polyurethane elastic 9 parts of body, 1.1 parts of foaming agent, 16 parts of epoxy soybean oil, 30 parts of modified attapulgite, 1.3 parts of lubricant, 1.5 parts of silicone masterbatch, 2 parts of stabilizer, 1.1 parts of pigment; Attapulgite is modified using the following steps:

[0040] (1) Crush the attapulgite, pass it through a 60-mesh sieve, soak it in an oxalic acid solution with a mass fraction of 5% for 1-2 hours, and then wash it with clean water until neutral;

[0041] (2) Soak the attapulgite treated in step (1) with 2.5% sodium dodecylbenzenesulfonate, which is 10 times the weight of the attapulgite, for 15-20 minutes, and use ultrasonic vibration treatment during the soaking process ;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Weft tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com