Attapulgite soil conditioner and preparation method thereof

A soil conditioner and attapulgite technology, applied in soil conditioning materials, chemical instruments and methods, other chemical processes, etc., can solve problems such as slow action effect, and achieve the effects of improving utilization rate, improving soil environment, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

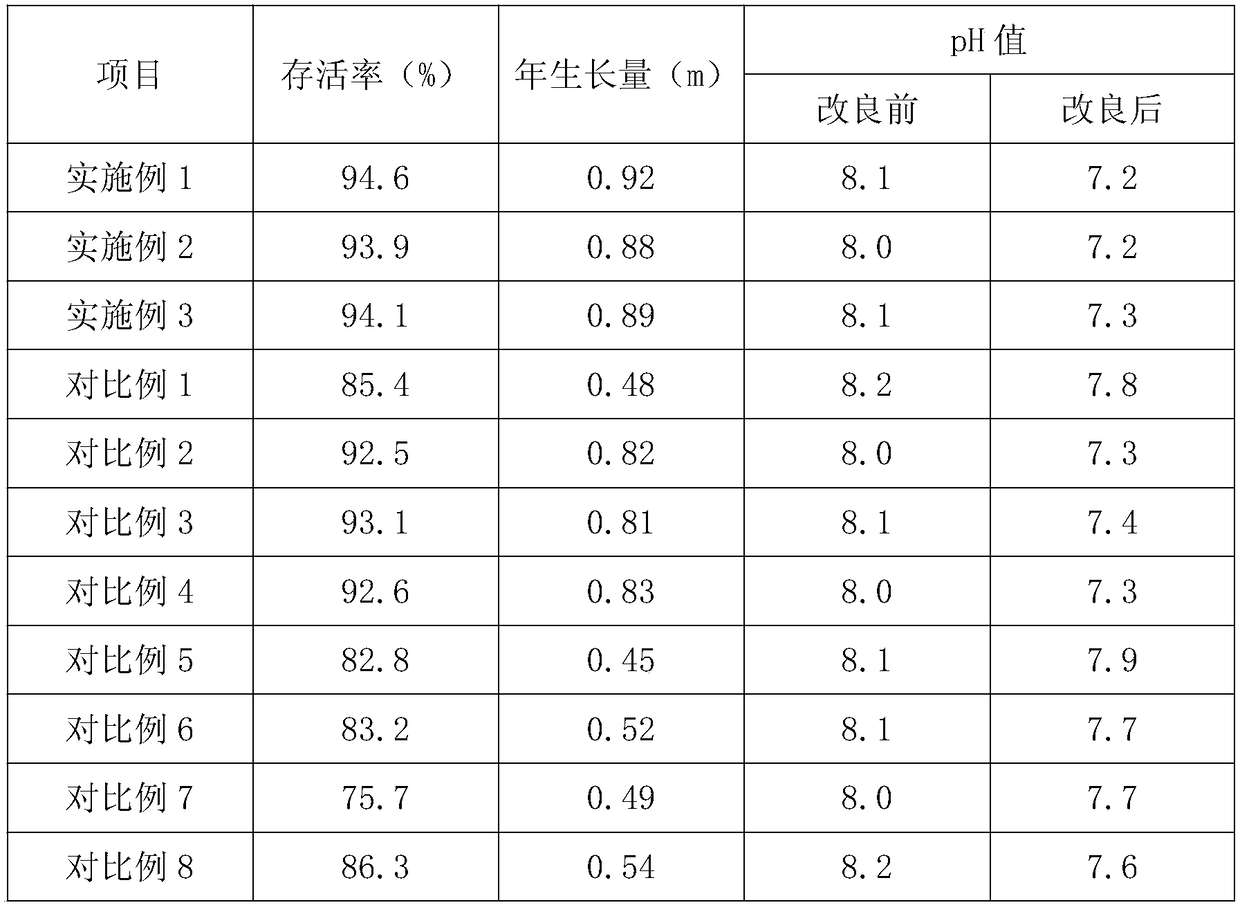

Examples

preparation example Construction

[0030] The preparation method of described attapulgite soil conditioner, comprises the following steps:

[0031] S1: After drying the corn stalks, mix the ore soil filler and coal stalks, put them into a pulverizer and grind them, and pass through a 50-mesh sieve to obtain the mixed material A;

[0032] S2: Mix the mixed material A with the mixed grass powder, stir evenly at a speed of 200-300r / min, add compound microorganisms and humic acid to ferment, ferment at a temperature of 50-60°C, and ferment for 15-20 days to obtain Mixture B;

[0033] S3: Weigh dimethyl diallyl ammonium chloride in proportion, dissolve it in water at 55-65°C, quickly add attapulgite, then add 2 parts of sulfuric acid, stir at constant temperature for 1-2h, then wash with ethanol Wash and centrifuge, then put it into a muffle furnace for calcination for 2 hours, and crush it to 200 mesh to obtain modified attapulgite;

[0034] S4: Mix mixed material A, mixed material B, modified attapulgite, urea, am...

Embodiment 1

[0036] A kind of attapulgite soil improver, in parts by weight, including the following raw materials: 30 parts of ore soil filler, 2 parts of coal stalks, 18 parts of corn stalks, 15 parts of mixed grass powder, 6 parts of compound microorganisms, humic acid 6 parts, 1 part of urea, 2 parts of ammonium dihydrogen phosphate, 1.5 parts of potassium chloride, 2 parts of desulfurized gypsum, 5 parts of attapulgite, 2.5 parts of dimethyl diallyl ammonium chloride, 1 part of calcium carbonate, poly 1.5 parts of acrylic superporous hydrogel particles.

[0037] The ore soil filler is a mixture of diatomite, talcum powder, and calcium carbonate in a weight ratio of 3:1:2; the mixed grass powder is tufted hair grass, perennial ryegrass, blunt-leaved grass, and red fescue grass A mixture composed according to a weight ratio of 3:2:1:1; the composite microorganism is a mixture composed of yeast, nitrogen-fixing bacteria, Aspergillus niger and Bacillus subtilis according to a weight ratio...

Embodiment 2

[0044] A kind of attapulgite soil improver, in parts by weight, including the following raw materials: 25 parts of ore soil filler, 5 parts of coal stalks, 15 parts of corn stalks, 20 parts of mixed grass powder, 5 parts of compound microorganisms, humic acid 4 parts, 3 parts of urea, 1 part of ammonium dihydrogen phosphate, 1 part of potassium chloride, 5 parts of desulfurized gypsum, 8 parts of attapulgite, 1 part of dimethyl diallyl ammonium chloride, 0.5 part of calcium carbonate, poly 0.3 parts of acrylic acid superporous hydrogel particles.

[0045] The ore soil filler is a mixture of diatomite, talcum powder, and calcium carbonate in a weight ratio of 3:1:2; the mixed grass powder is tufted hair grass, perennial ryegrass, blunt-leaved grass, and red fescue grass A mixture composed according to a weight ratio of 3:2:1:1; the composite microorganism is a mixture composed of yeast, nitrogen-fixing bacteria, Aspergillus niger and Bacillus subtilis according to a weight rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com