Compost-type degradable garbage bag thin film material and manufacturing method thereof

A technology of film material and degradable material, which is applied in the field of compostable degradable garbage bag film material and its preparation field, can solve problems such as being difficult to degrade, and achieve the effects of reducing garbage volume, improving use efficiency, and accelerating garbage decomposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

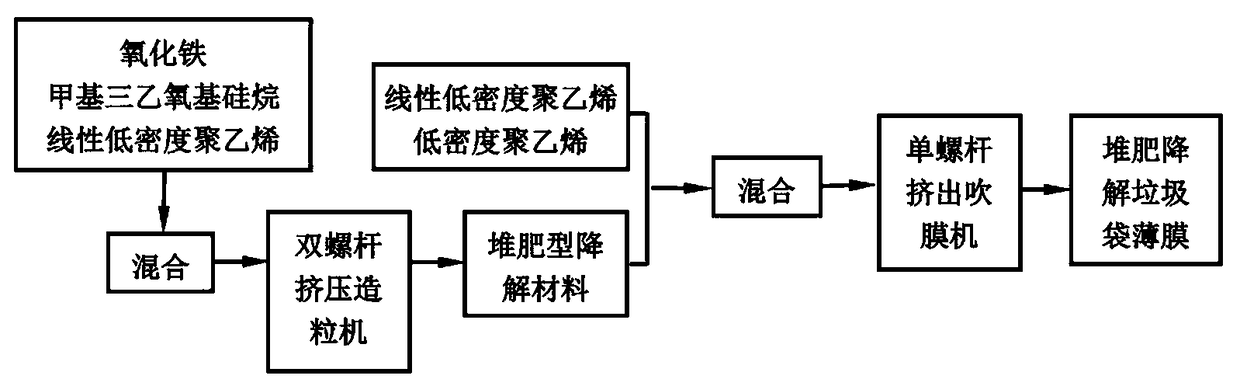

Method used

Image

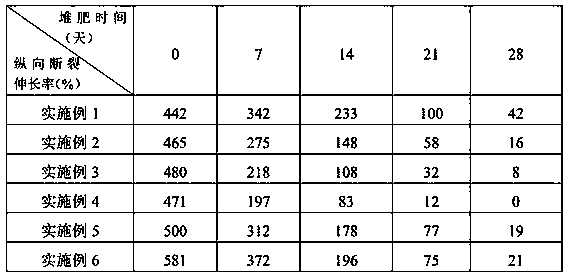

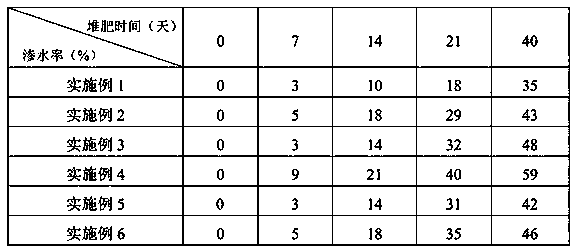

Examples

Embodiment 1

[0024] (I) Compostable degradable material formula (kg):

[0025] Iron oxide (through a 1000-mesh sieve, the sieve is 5%, and the undersieve is passed through a 1350-mesh sieve, the sieve is 20%): 5

[0026] Triethanolamine borate: 0

[0027] Linear Low Density Polyethylene: 95

[0028] (II) Preparation of compostable degradable materials:

[0029] The first step: Put the weighed iron oxide, triethanolamine borate and linear low density polyethylene into the heating mixer for mixing. The speed of the heating mixer is 800rpm, and the stirring temperature is 50~60 o C, the stirring time is 8min.

[0030] The second step: the mixture is granulated in a twin-screw extrusion granulator to prepare compostable degradable materials. The screw length-to-diameter ratio L / D of the twin-screw extrusion granulator is 40, and the temperature in the granulation stage is 165°C~175°C.

[0031] (III) Compostable garbage bag film material formula (kg):

[0032] Compostable Degradable Mater...

Embodiment 2

[0039] (I) Compostable degradable material formula (kg):

[0040] Iron oxide (through a 800-mesh sieve, the sieve is 5%, and then the undersieve is passed through a 1000-mesh sieve, the sieve is 10%): 20

[0041] Methyltriethoxysilane: 0.3

[0042] Linear Low Density Polyethylene: 79.7

[0043] (II) Preparation of compostable degradable materials:

[0044] The first step: Put the weighed iron oxide, methyltriethoxysilane and linear low density polyethylene into a high-speed heating mixer for mixing. The speed of the heating mixer is 900rpm, and the stirring temperature is 50~60 o C, the stirring time is 9min.

[0045] The second step: the mixture is granulated in a twin-screw extrusion granulator to prepare compostable degradable materials. The screw length-to-diameter ratio L / D of the twin-screw extrusion granulator is 45, and the temperature in the granulation stage is 175°C~185°C.

[0046] (Ⅲ) Compostable garbage bag film material formula (kg):

[0047] Compostable De...

Embodiment 3

[0054] (I) Compostable degradable material formula (kg):

[0055] Iron oxide (through a 800-mesh sieve, the sieve residue is 7%, and the under-sieve passes through a 1000-mesh sieve, the sieve residue is 20%): 20

[0056] Methyltriethoxysilane: 0.3

[0057] Linear Low Density Polyethylene: 79.7

[0058] (II) Compostable garbage bag film material formula (kg):

[0059] Compostable Degradable Materials: 20

[0060] LDPE: 3

[0061] Linear Low Density Polyethylene: 77

[0062] The film thickness of the garbage bag prepared by blown film is 20 microns.

[0063] The process of compostable degradable material preparation and compostable garbage bag film preparation in embodiment 3 is the same as that in embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com