Ceramic slurry, ceramic device and preparation method thereof

A technology of ceramic slurry and ceramics, which is applied in the field of ceramic devices and its preparation, and ceramic slurry, which can solve the problems of unfavorable human health and environmental protection, lower product yield, and easy cracking of ceramic green body, and achieve high mechanical strength, Improve product yield and reduce cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of above-mentioned ceramic slurry, comprises the following steps:

[0046] Provide the above-mentioned raw materials for ceramic slurry;

[0047] Fine fused silica powder, dispersant, gelling agent and water are mixed and ball milled, then coarse fused silica powder is added to continue ball milling to obtain ceramic slurry.

[0048] When the raw material of the ceramic slurry also includes an initiator, the initiator is added after the coarse fused silica powder is added and ball milling is completed. The initiator is added after the other components are fully mixed to avoid premature addition of the initiator to affect the uniformity of component mixing.

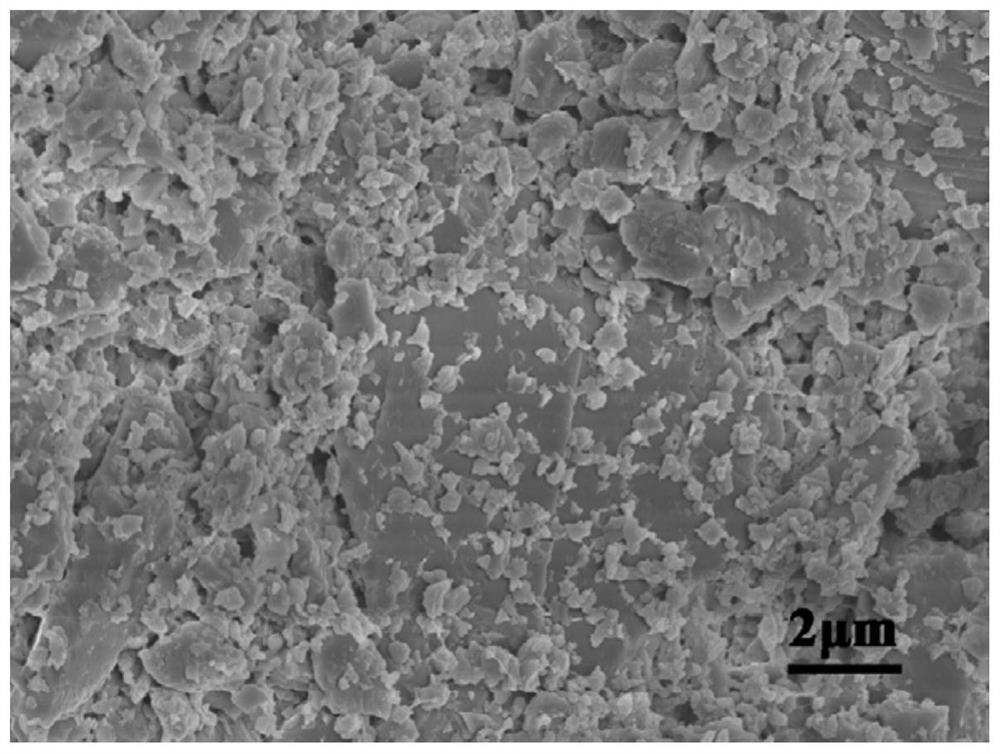

[0049] In this way, the fine fused silica powder, dispersant, gelling agent and water are first added to a ball mill and ground for a period of time; then the coarse fused silica powder is added to the above slurry and continued to be ground for a period of time to obtain a ceramic slurry. I...

Embodiment 1

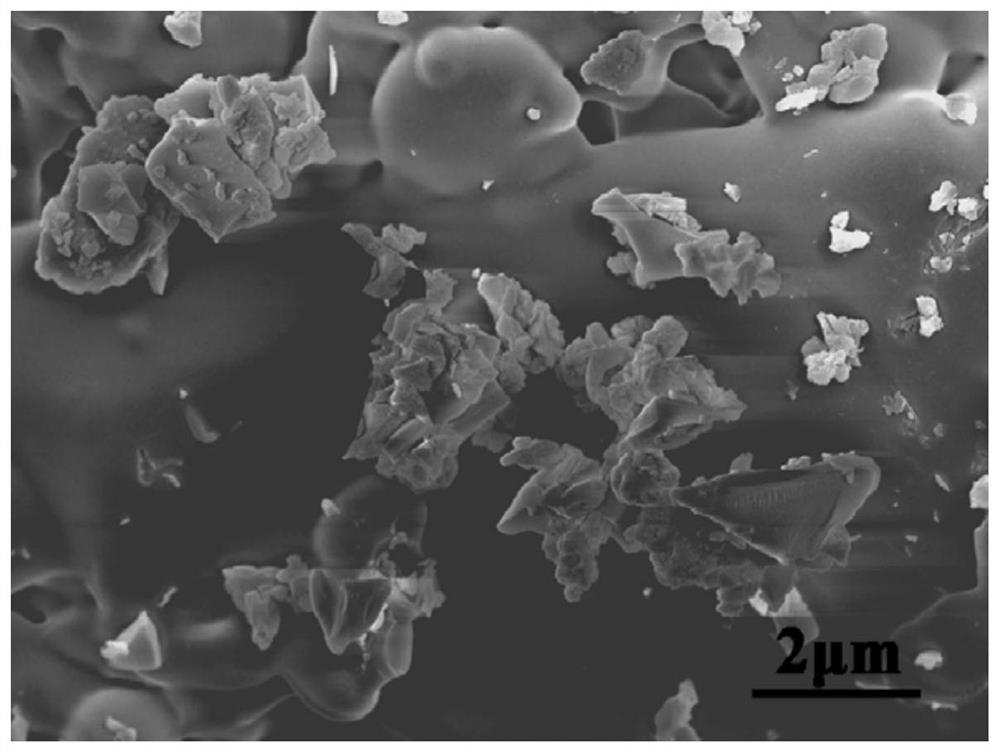

[0061] Put 1 part of water, 2.6 parts of fine fused silica powder, dispersant, gelling agent, etc. into the ball mill and mill at a speed of 160rpm for 4 hours to prepare the initial fused silica slurry, and then add 1.4 parts to the above slurry The coarse fused silica powder of 1000mm of quality is continued ball milling 15min under the rotating speed of 120rpm, adds the ammonium persulfate (the aqueous solution that is pre-configured as 10% mass concentration) that accounts for 2% of gelling agent quality in the slurry after ball milling, obtains required ceramic slurry. Then vacuum defoam the ceramic slurry, pour it into the crucible mold after defoaming, place the mold in a water bath environment at 70°C for 1 hour, and then get the fused silica crucible body after demoulding, and the body is dried under temperature control and humidity control Afterwards, it is fired in a kiln at 1150°C for 5 hours to obtain a fused silica ceramic crucible. The median diameter of the fi...

Embodiment 2

[0063] Put 1 part of water, 3.3 parts of fine fused silica powder, dispersant, gel, etc. into the ball mill and mill at a speed of 220rpm for 5 hours to prepare the initial fused silica slurry, and then add 3.3 parts to the above slurry The thick fused silica powder of 1000g quality is that the rotating speed is 80rpm and continues ball milling 25min, adds the ammonium persulfate (the aqueous solution that is preconfigured as the aqueous solution of 10% mass concentration) that accounts for 2% of gelling agent quality in the slurry after ball milling to obtain required ceramic slurry. Then vacuum defoam the ceramic slurry, pour it into the crucible mold after degassing, place the mold in a water bath environment at 75°C for 1 hour, and then get the fused silica crucible body after demoulding, and the body is dried under temperature control and humidity control Afterwards, it is fired in a kiln at 1200°C for 3 hours to obtain a fused silica ceramic crucible. The median diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com