Impervious high-strength alkali-free liquid accelerator and preparation method thereof

A high-strength, quick-setting agent technology, applied in the field of impervious high-strength alkali-free liquid quick-setting agent and its preparation, can solve the problems of poor stability, large drop in shotcrete strength, short storage period, etc., to reduce dust concentration and Resilience, avoiding no rust effect, no irritating smell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described impervious high-strength type non-alkali liquid quick-setting agent, it comprises the following steps:

[0029] S1. Preparation of organic modifier: Add alcoholamine, hydroxypropyl methylcellulose and polyacrylamide in a weight ratio of 10:0.25:1 into a container filled with water under stirring, and heat to 40~ 50°C, continue to stir for 30-60 minutes, until the components are completely dissolved, so as to prepare the organic modifier;

[0030] S2. Add hydrated magnesium silicate and inorganic salts into a vessel filled with water while stirring, add aluminum sulfate to the vessel after they are completely dissolved, raise the temperature to 70-80°C, keep warm for 1-2 hours, and wait until the aluminum sulfate is completely dissolved Finally, add inorganic acid and continue to stir for 10-12 minutes to obtain a uniform and stable solution;

[0031] S3. Add the organic modifier prepared in step S1 into the vessel under stirring, kee...

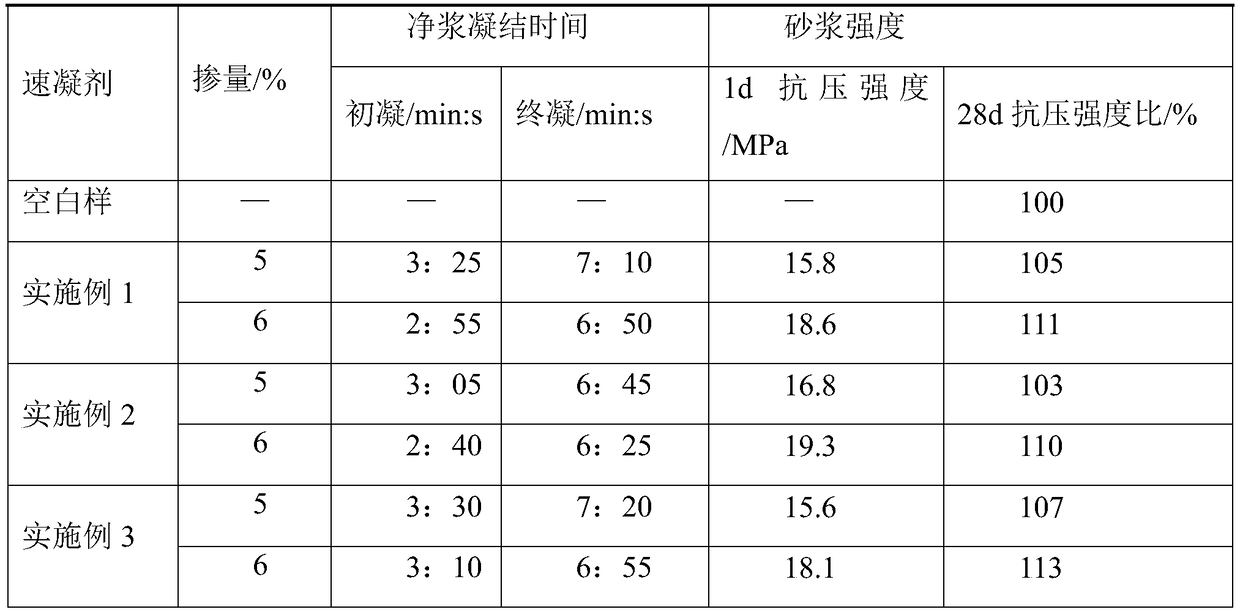

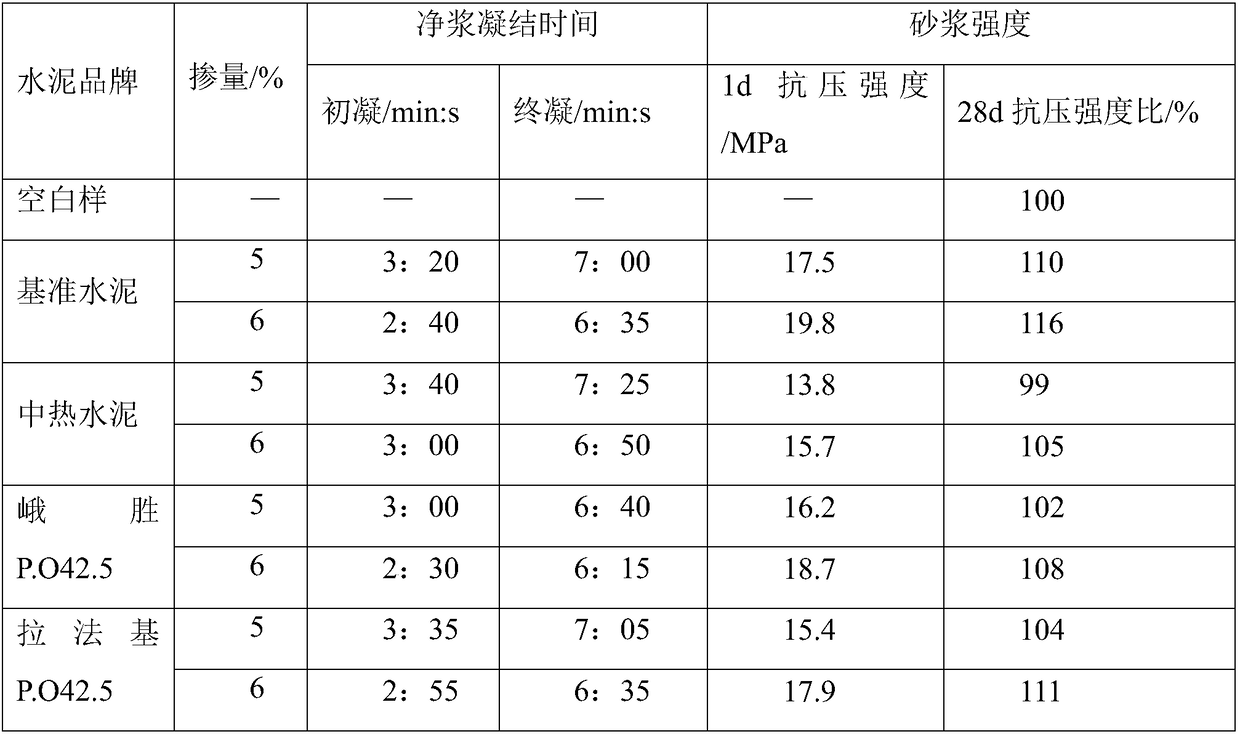

Embodiment 1

[0033] The preparation method of impervious high-strength type non-alkali liquid quick-setting agent, it comprises the following steps:

[0034] S1. Preparation of organic modifier: Add 4 parts of diethanolamine, 0.1 part of hydroxypropyl methylcellulose and 0.4 part of polyacrylamide into a container containing 8 parts of water under stirring, and heat to 40-50 ℃, continue to stir for 30-60 minutes until all components are completely dissolved;

[0035] S2. Add 0.5 parts of hydrated magnesium silicate, 8 parts of sodium fluoride, and 1 part of magnesium fluorosilicate into the water containing 27.8 parts of utensils under stirring. After completely dissolving, add 50 parts of aluminum sulfate and heat up to 70-80 ℃, keep warm for 1-2 hours, add 0.2 parts of sulfuric acid after the aluminum sulfate is completely dissolved, and continue stirring for 10-12 minutes to obtain a uniform and stable solution;

[0036] S3. Add the modifying agent to the above solution under stirring ...

Embodiment 2

[0038] The preparation method of impervious high-strength type non-alkali liquid quick-setting agent, it comprises the following steps:

[0039] S1. Preparation of organic modifier: Add 4 parts of triethanolamine, 0.1 part of hydroxypropyl methylcellulose and 0.4 part of polyacrylamide into a container containing 8 parts of water under stirring, and heat to 40-50 ℃, continue to stir for 30-60 minutes until all components are completely dissolved;

[0040] S2. Add 0.6 parts of hydrated magnesium silicate and 10 parts of magnesium sulfate into a container containing 21.7 parts of water while stirring, add 55 parts of aluminum sulfate after completely dissolving, heat up to 70-80°C, keep warm for 1 hour, and wait for sulfuric acid After the aluminum is completely dissolved, add 0.2 parts of phosphoric acid and continue stirring for 10-12 minutes to obtain a uniform and stable solution;

[0041] S3. Add the modifying agent to the above solution under stirring state, keep it warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com