Dyeing and printing wastewater sludge reduction treatment apparatus and method

A technology for printing and dyeing wastewater and treatment device, which is applied in water/sludge/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Simple treatment process and the effect of reducing the amount of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

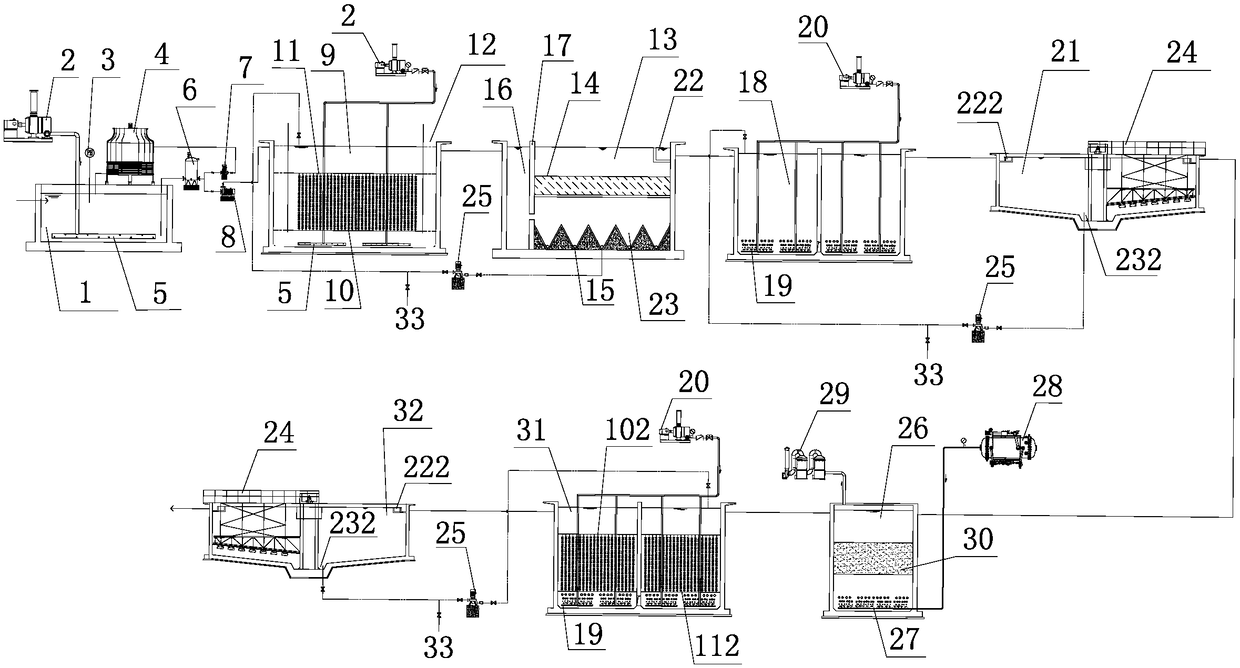

[0041] Such as figure 1 Shown: a printing and dyeing wastewater sludge reduction treatment device, including a regulating tank 1 connected by pipelines, a hydrolytic acidification tank 9, a middle sedimentation tank 13, an aerobic tank 18, a secondary sedimentation tank 21, an ozone oxidation tank 26, a contact Oxidation pool 31 and final sedimentation pool 32, the printing and dyeing wastewater passes through the regulating pool, the hydrolysis acidification pool, the intermediate sedimentation pool, the aerobic pool, the secondary sedimentation pool, the ozone oxidation pool, the The contact oxidation tank and the middle sedimentation tank are used for printing and dyeing wastewater sludge reduction treatment.

[0042] A perforated aeration pipe 5 is provided at the inner bottom of the regulating tank, and a first fan 2 connected to the perforated aerating pipe, a pH automatic detection and adjusting device 3, a cooling tower 4, a water diversion tank 6, a cooling tower, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com