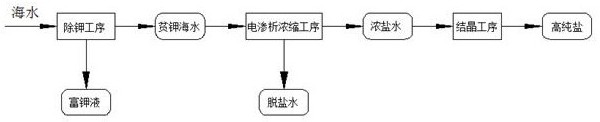

A process for producing high-purity refined salt by using selective electrodialysis to concentrate brine

An electrodialysis and selective technology, which is applied in general water supply saving, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high impurity content in concentrated brine, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The influent water in this embodiment is seawater outside Quanzhou Bay, Cl - Content 17.01 g / L, Ca 2+ Content 0.71 g / L, Mg 2+ Content 0.95 g / L, SO 4 2- Content 1.23 g / L, Na + Content 8.75 g / L, K + Content 0.37 g / L.

[0024] Potassium removal process: Control seawater to be pumped into the ion exchange column equipped with modified sodium clinoptilolite at a flow rate of 15 m / h for potassium ion adsorption, so that the potassium ion content in potassium-poor seawater after adsorption is less than 0.01 g / L After the adsorption is completed, the saturated brine obtained by saturated halide salts is eluted with a flow rate of 5 m / h to obtain a potassium-rich liquid, wherein the content of potassium ions is 19.34 g / L.

[0025] Electrodialysis concentration process: pump potassium-poor seawater with a pH of 6 into the electrodialyzer, and control the recovery rate of the electrodialyzer by adjusting the operating voltage and water inflow. Under the condition of 50%, the...

Embodiment 2

[0028] The influent in this embodiment is seawater outside the Bohai Bay, Cl - Content 19.56 g / L, Ca 2+ Content 0.41 g / L, Mg 2+ Content 1.29 g / L, SO 4 2- Content 2.35 g / L, Na + Content 11.32 g / L, K + Content 0.41 g / L.

[0029] Potassium removal process: Control seawater to be pumped into the ion exchange column equipped with modified sodium clinoptilolite at a flow rate of 18 m / h for potassium ion adsorption, so that the potassium ion content in potassium-poor seawater after adsorption is less than 0.02 g / L After the adsorption is completed, the saturated brine obtained by saturated halide salts is eluted with a flow rate of 4 m / h to obtain a potassium-rich liquid, wherein the potassium ion content is 20.25 g / L.

[0030] Electrodialysis concentration process: pump potassium-poor seawater with pH adjusted to 5 into the electrodialyzer, and control the recovery rate of the electrodialyzer by adjusting the operating voltage and water inflow. Under the condition of 45%, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com