SnBiAgCu high-reliability lead-free solder alloy

A lead-free solder alloy, reliable technology, applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of poor wettability, poor reliability, poor fluidity, etc., and achieve long-lasting oxidation resistance and soldering Stable quality and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

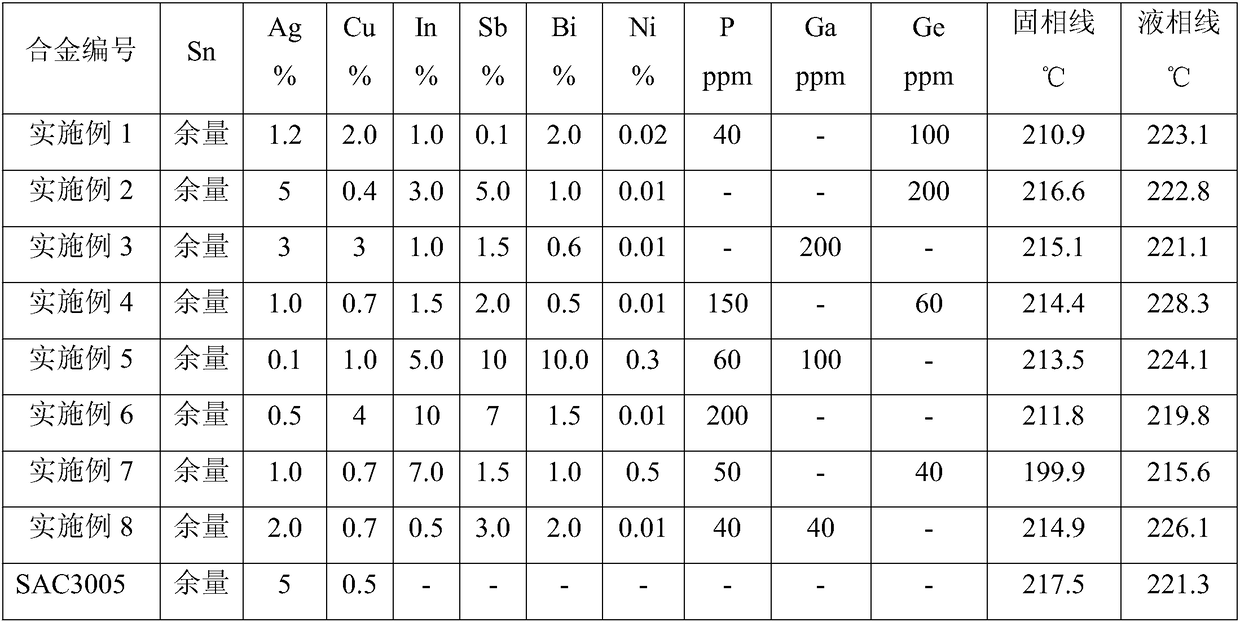

[0030] The present invention will be described in further detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited to the content described.

[0031] The weight percent of SnBiAgCu high reliability lead-free solder of the present invention consists of:

[0032] 0.1-5% Ag;

[0033] 0.4-4% Cu;

[0034] 0.5-10% In;

[0035] 0.1-10% Sb;

[0036] 0.5-10% Bi;

[0037] 0.01-0.5% Ni;

[0038] Compound addition of any one, two or three of the following elements, the total amount is in the range of 0-0.1%:

[0039] 0-200ppm P;

[0040] 0-200ppm of Ga;

[0041] 0-200ppm of Ge;

[0042] And the balance of Sn and unavoidable impurities.

[0043] During the preparation process of the lead-free solder, Ag, Cu, Sb, In, Ni, Ge, and P are prepared as SnX master alloys and added, the remaining Bi and Ga are added as pure substances, and the insufficient Sn is added as pure Sn.

[0044] The above-mentioned master alloy of Ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com