Formation method of I-shaped steel for nuclear fusion reactor magnet supporting

A technology of I-shaped steel and magnet support, applied in the direction of metal rolling, etc., can solve the problems of reduced comprehensive performance, large machining allowance, waste of raw materials, etc., achieve high pressure and corrosion resistance processing cost, small machining allowance, and forming fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described with reference to the examples of the above drawings.

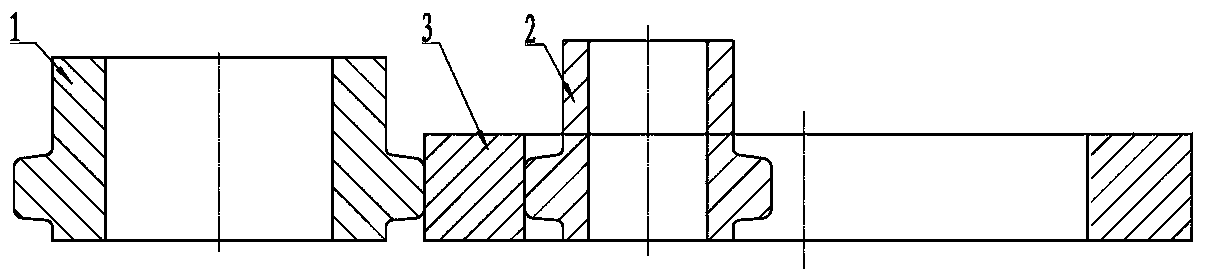

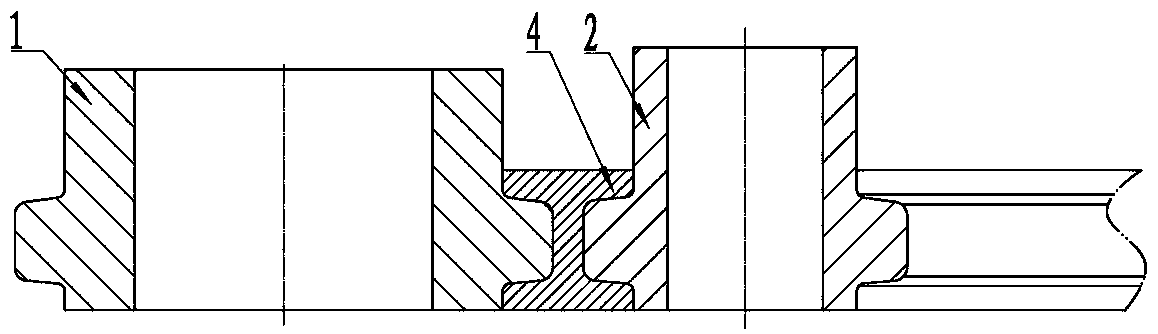

[0019] The special forming method of the I-shaped steel used for nuclear fusion reactor magnet support uses a mold consisting of two parts: the main roller mold 1 and the core roller mold 2. The method is divided into three steps:

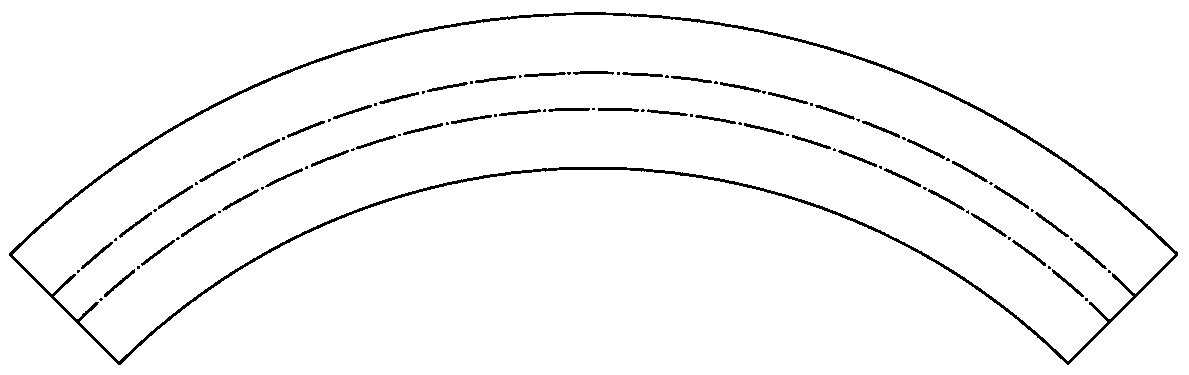

[0020] The first step: the preparation of the ring blank 3: firstly, the steel ingot is heated to 1150°C for forging to change its structural state, weld the internal defects, and make the ring blank 3 through the process of punching and reaming. The cross-sectional size of the shaped steel remains consistent when it is formed, and the ring blank 3 is made of a combination of multiple I-shaped steels;

[0021] Step 2: Manufacture of I-shaped cross-section ring rolling 4: Assemble the main roll mold 1 on the main roll of the ring rolling mill, assemble the core roll mold 2 on the ring rolling mandrel roll, and form the main roll mold 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com