A kind of nano ruthenium carbon catalyst and its preparation method and application

A carbon catalyst and nano-ruthenium technology, which is applied in the field of high-selectivity and high-stability nano-ruthenium carbon catalyst and its preparation, can solve the problems of low catalytic selectivity and stability, avoid desorption and migration, reduce industrial waste, and reduce reaction mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] One aspect of the embodiments of the present invention provides a method for preparing a nano-ruthenium carbon catalyst, which is prepared by stepwise deposition and precipitation combined with staged roasting, specifically including:

[0024] Provide activated carbon as a carrier;

[0025] Immersing the activated carbon in an aqueous ruthenium salt solution, adding a basic compound, stirring and standing, filtering, drying and roasting to obtain the first ruthenium carbon precursor;

[0026] Immersing the first ruthenium-carbon precursor in an auxiliary aqueous solution, adding a basic compound, stirring and standing, filtering, and then drying to obtain a second ruthenium-carbon precursor;

[0027] In a protective atmosphere, the second ruthenium carbon precursor is subjected to segmental roasting treatment to obtain the third ruthenium carbon precursor;

[0028] The third ruthenium carbon precursor is reduced to obtain a nanometer ruthenium carbon catalyst.

[0029...

Embodiment 1

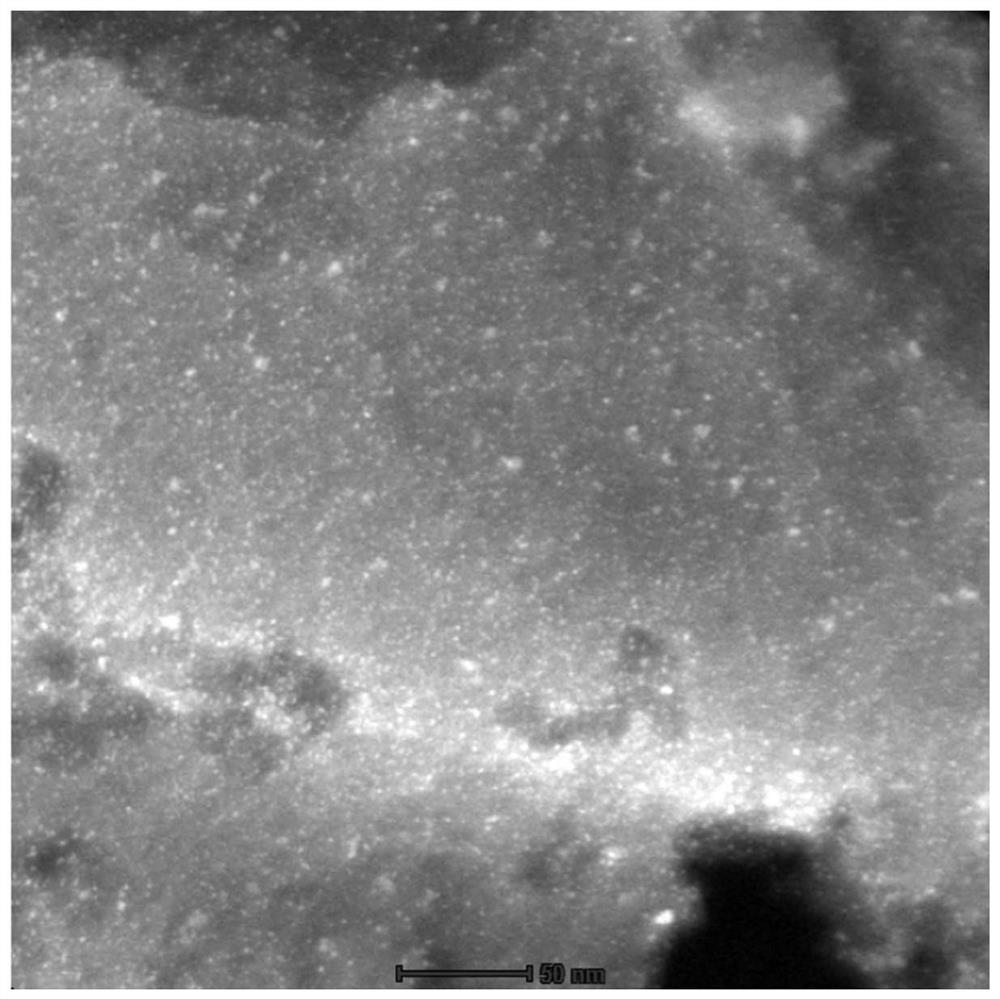

[0071] Weigh 50.00 g of pretreated activated carbon, add it to 300 mL of aqueous solution containing 5.56 g of ruthenium trichloride hydrate and stir for 3.0 h, then use 1.0 mol L -1 Adjust the pH of the mixed slurry to 9.0 with aqueous sodium hydroxide solution, continue to stir for 4.0 h, let it stand for 2.0 h, filter, wash the filter cake with water until it is neutral and free of chloride ions, and then dry it at 100°C for 4.0 h. 2 Calcined at 250° C. for 3.0 h under atmosphere, then added to an aqueous solution containing 4.84 g of zinc nitrate hexahydrate and continued to stir for 2.0 h. The pH adjustment and drying process were the same as above. in N 2 In the atmosphere, it was fired at 150°C for 4.0h, then at 400°C for 4.0h, and finally in H 2 :N 2 = 1:9 (v / v) reduction at 200° C. for 3.0 h in an atmosphere to obtain a nano-ruthenium carbon catalyst with a dispersion of 79.5%, a ruthenium loading of 4.0%, and a zinc loading of 2.0%. The HADDF-STEM figure of the ob...

Embodiment 2

[0073] Weigh 50.00 g of pretreated activated carbon, add it to 300 mL of aqueous solution containing 6.10 g of ruthenium acetylacetonate and stir for 0.5 h, then use 1.0 mol L -1 Adjust the pH of the mixed slurry to 12.0 with sodium carbonate aqueous solution, continue to stir for 1.0 h, let it stand for 2.0 h, filter, wash the filter cake with water until it is neutral and free of chloride ions, then dry it at 120 ° C for 4.0 h, and then dry it under N 2 Calcined at 400°C for 4.0 hours under atmosphere, then added to an aqueous solution containing 4.00 g of copper nitrate trihydrate and continued to stir for 4.0 hours, and the pH adjustment and drying process were the same as above. in N 2 In the atmosphere, first bake at 300°C for 2.0h, then at 600°C for 2.0h, and finally in H 2 :N 2 =3:7 (v / v) reduction at 120° C. for 10.0 h in an atmosphere to obtain a nano-ruthenium carbon catalyst with a dispersion of 72.2%, a ruthenium loading of 3.0%, and a copper loading of 2.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com