Preparation method of double-layer artificial small-diameter blood vessel with modified inner layer

A small-diameter, inner-layer technology, applied in the manufacture of rayon, single-component polyurethane rayon, conjugated synthetic polymer rayon, etc. Compatibility and degradation performance, no inflammatory reaction, good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

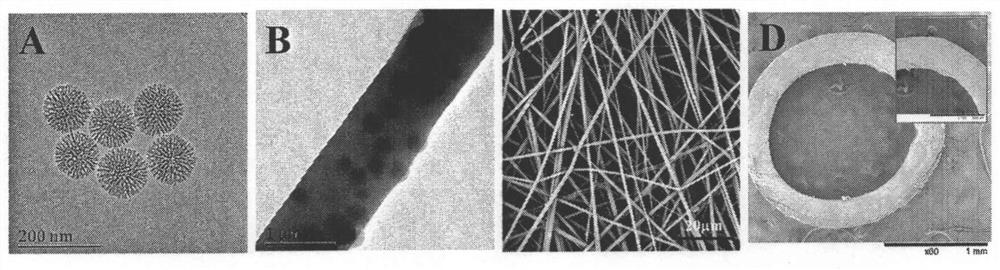

[0028] A method for preparing a composite double-layer artificial small-caliber blood vessel with an inner layer modified by MSN-PEG-Heparin:

[0029] (1) Ultrasonic disperse 40 mg of carboxylated mesoporous silicon (MSNs-COOH) into 20 mL of 0.01N NaOH, stir for 10 minutes and centrifuge for 20 minutes, and wash the MSNs with water for 3 times; then, MSNs are dispersed in 10 mL of 0.05M In the mixed solution of MES and 0.5M NaCl, after stirring for 1 hour, 0.12M EDC, 2mg / mL PEG and 0.06M NHS were added. The mixture solution was stirred at room temperature for 16 hours. The final product was washed with water for 3 times and centrifuged to obtain MSN-PEG;

[0030] (2) Disperse 40 mg of the prepared MSN-PEG in 10 mL of 15% heparin solution and stir for 24 hours. MSN-PEG-Heparin was obtained after centrifugation;

[0031] (3) Disperse the MSN-PEG-Heparin prepared in (2) in HFIP (3mg / mL), then sonicate for 30 minutes to ensure uniform dispersion;

[0032] (4) Prepare the inner...

Embodiment 2

[0036] A method for preparing a composite double-layer artificial small-caliber blood vessel with an inner layer modified by MSN-PEG-Heparin:

[0037] (1) Ultrasonic disperse 40 mg of carboxylated mesoporous silicon (MSNs-COOH) into 20 mL of 0.01N NaOH, stir for 10 minutes and centrifuge for 20 minutes, and wash the MSNs with water for 3 times; then, MSNs are dispersed in 10 mL of 0.05M In the mixed solution of MES and 0.5M NaCl, after stirring for 1 hour, 0.12M EDC, 2mg / mL PEG and 0.06M NHS were added. The mixture solution was stirred at room temperature for 16 hours. The final product was washed with water for 3 times and centrifuged to obtain MSN-PEG;

[0038] (2) Disperse 40 mg of the prepared MSN-PEG in 10 mL of 15% heparin solution and stir for 24 hours. MSN-PEG-Heparin was obtained after centrifugation;

[0039](3) Disperse the MSN-PEG-Heparin prepared in (2) in HFIP (3mg / mL), then sonicate for 30 minutes to ensure uniform dispersion;

[0040] (4) Prepare the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com