Amphiphilic chitosan-macadamia nut oil nano-microcapsules and its preparation method and application

A technology of nano-microcapsules and chitosan, applied in the directions of microcapsules, application, capsule delivery, etc., can solve the problems of short fragrance retention time, low antioxidant capacity, and oxidative deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

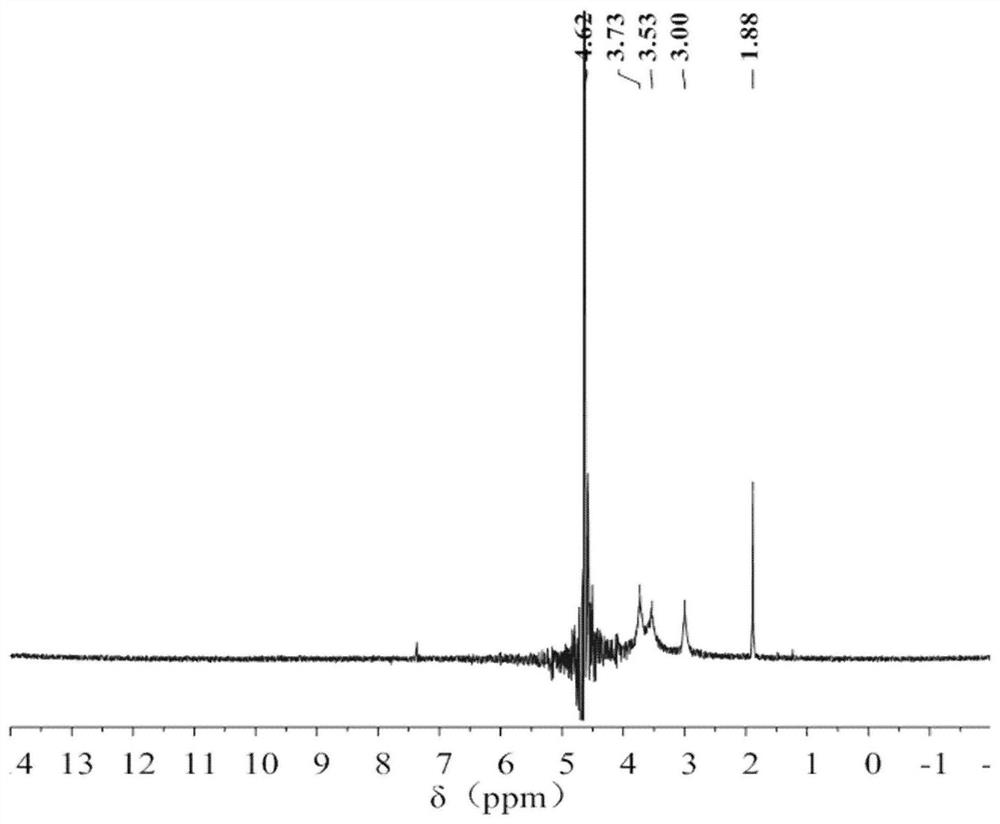

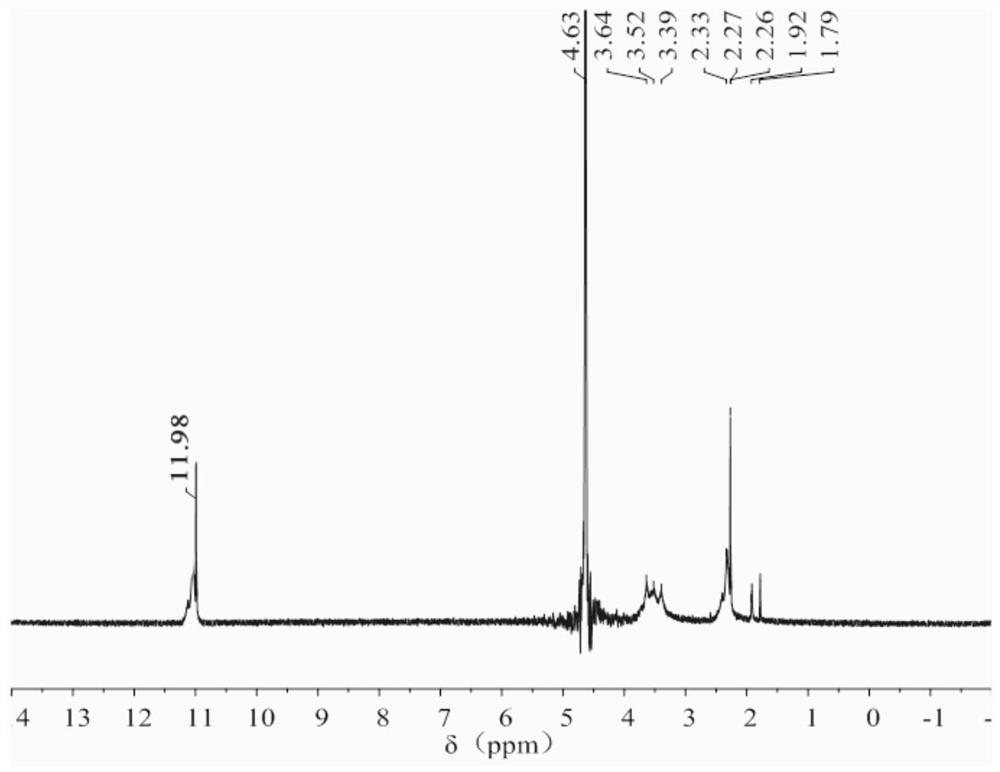

[0042] The preparation of embodiment 1 amphiphilic chitosan

[0043] (1) Get the chitosan that viscosity is not more than 200mPa.s, be configured into the chitosan aqueous solution that mass concentration is 1.0% with the glacial acetic acid aqueous solution of 1.0% with mass concentration; Get stearic acid, be configured with dehydrated alcohol into mass concentration Concentration is the ethanol solution of stearic acid of 2.0%;

[0044] (2) getting 1kg of the above-mentioned mass concentration of 1.0% chitosan aqueous solution and 1kg of the above-mentioned mass concentration of 2.0% stearic acid ethanol solution, mix, stir and add 10g of 1-ethyl-3-(3-di Methylaminopropyl) carbodiimide hydrochloride, at a temperature of 80°C and a stirring speed of 3000rpm, stirring and reacting for 3h, grafting stearic acid into chitosan molecules as a hydrophobic group to obtain hard Stearic acid grafted chitosan with fatty acid hydrophobic group grafting ratio of 5%;

[0045] (3) Step ...

Embodiment 2

[0048] The preparation of embodiment 2 amphiphilic chitosan

[0049] (1) Get the chitosan that viscosity is not more than 200mPa.s, be configured into the chitosan aqueous solution that mass concentration is 3.0% with the glacial acetic acid aqueous solution of 1.0% with mass concentration; Get stearic acid, be configured with dehydrated alcohol into mass concentration Concentration is the ethanol solution of stearic acid of 5.0%;

[0050] (2) getting 1kg of the above-mentioned mass concentration of 3.0% chitosan aqueous solution and 1kg of the above-mentioned mass concentration of 5.0% stearic acid ethanol solution, mix, stir and add 100g of 1-ethyl-3-(3-di Methylaminopropyl) carbodiimide hydrochloride, at a temperature of 80°C and a stirring speed of 1000rpm, stirring and reacting for 5h, grafting stearic acid into the chitosan molecule as a hydrophobic group to obtain hard Stearic acid grafted chitosan with fatty acid hydrophobic group grafting ratio of 20%;

[0051] (3) ...

Embodiment 3

[0052] The preparation of embodiment 3 amphiphilic chitosan

[0053] (1) Get the chitosan that viscosity is not more than 200mPa.s, be configured into the chitosan aqueous solution that mass concentration is 2.0% with the glacial acetic acid aqueous solution of 1.0% with mass concentration; Get stearic acid, be configured with dehydrated alcohol into mass concentration Concentration is the stearic acid ethanol solution of 3.0%;

[0054] (2) get 1kg above-mentioned mass concentration and be that the chitosan aqueous solution of 2.0% and 1kg above-mentioned mass concentration are the stearic acid ethanol solution of 3.0%, mix, add 80g of 1-ethyl-3-(3-di Methylaminopropyl) carbodiimide hydrochloride, at a temperature of 80°C and a stirring speed of 2000rpm, stirring and reacting for 4h, grafting stearic acid into the chitosan molecule as a hydrophobic group to obtain hard Stearic acid grafted chitosan with fatty acid hydrophobic group grafting ratio of 10%;

[0055] (3) Add 140...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com