Amphiphilic chitosan-macadamia oil nano microcapsules and preparation method and application thereof

A technology of nano-microcapsules and chitosan, which is applied in the direction of micro-capsules, application, capsule delivery, etc., can solve the problems of restricting the application and development of macadamia nut oil, the instability of macadamia nut oil, and poor skin absorption effect, so as to achieve convenient storage Transportation and application, reducing volatility and photothermal instability, delaying the effect of volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

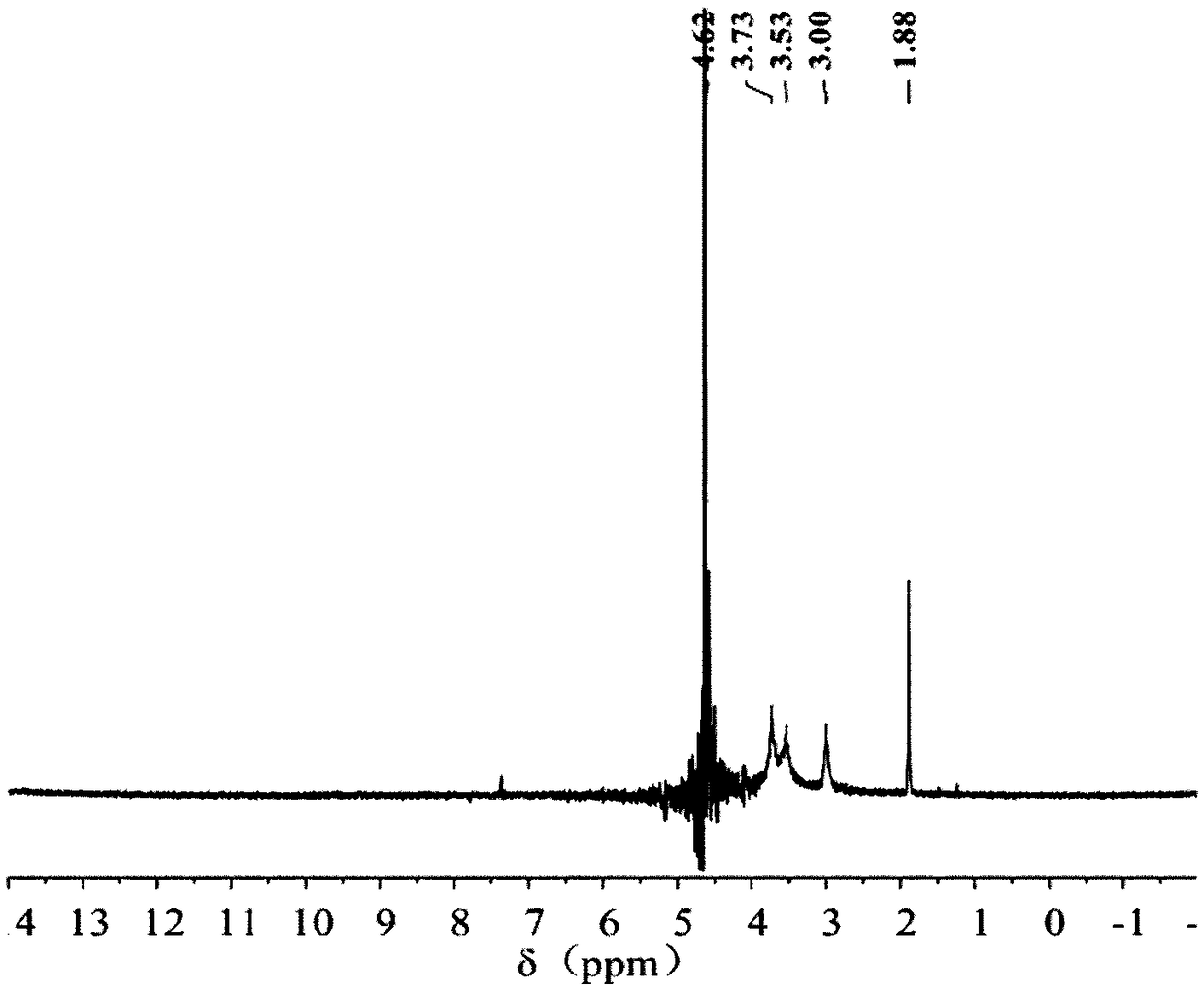

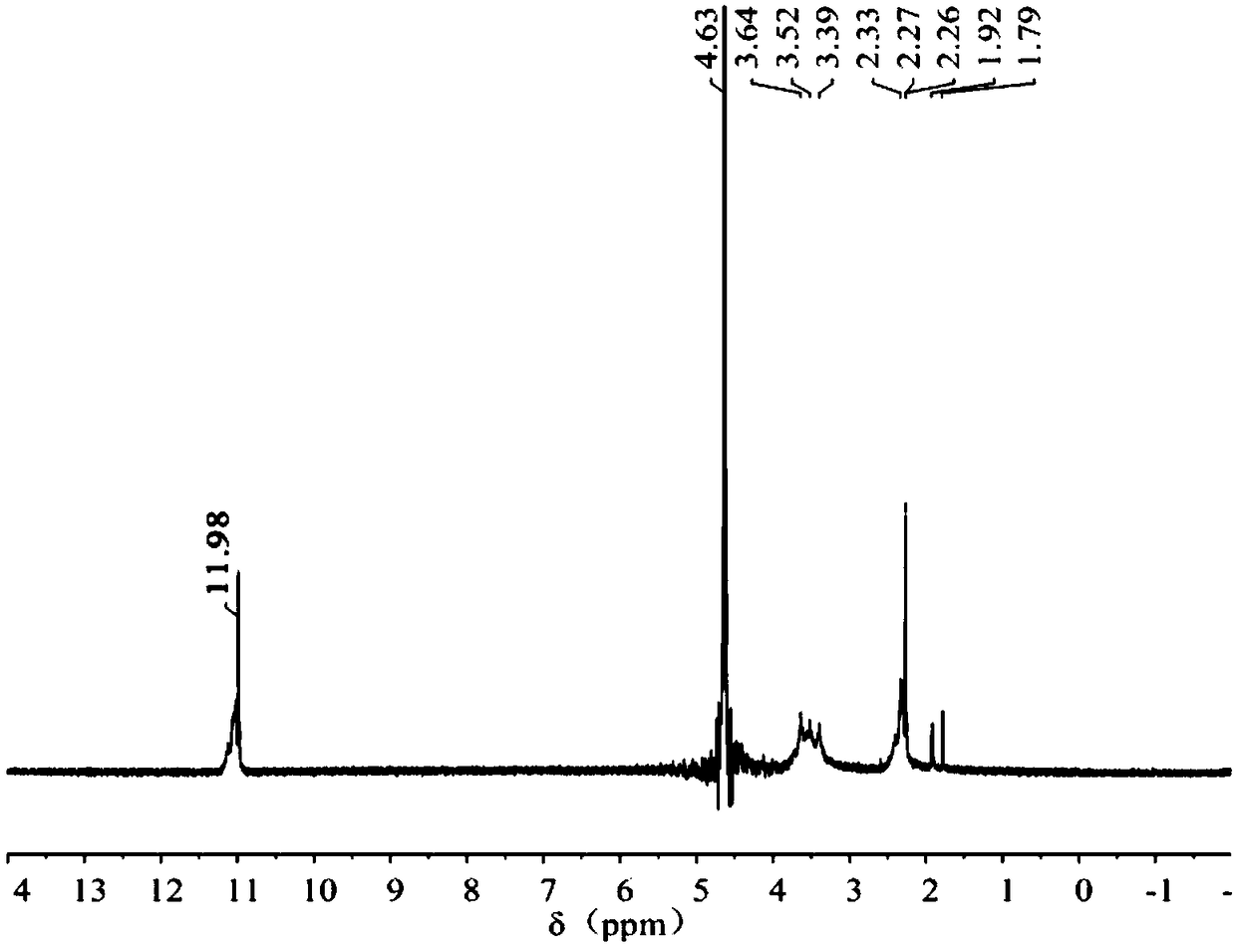

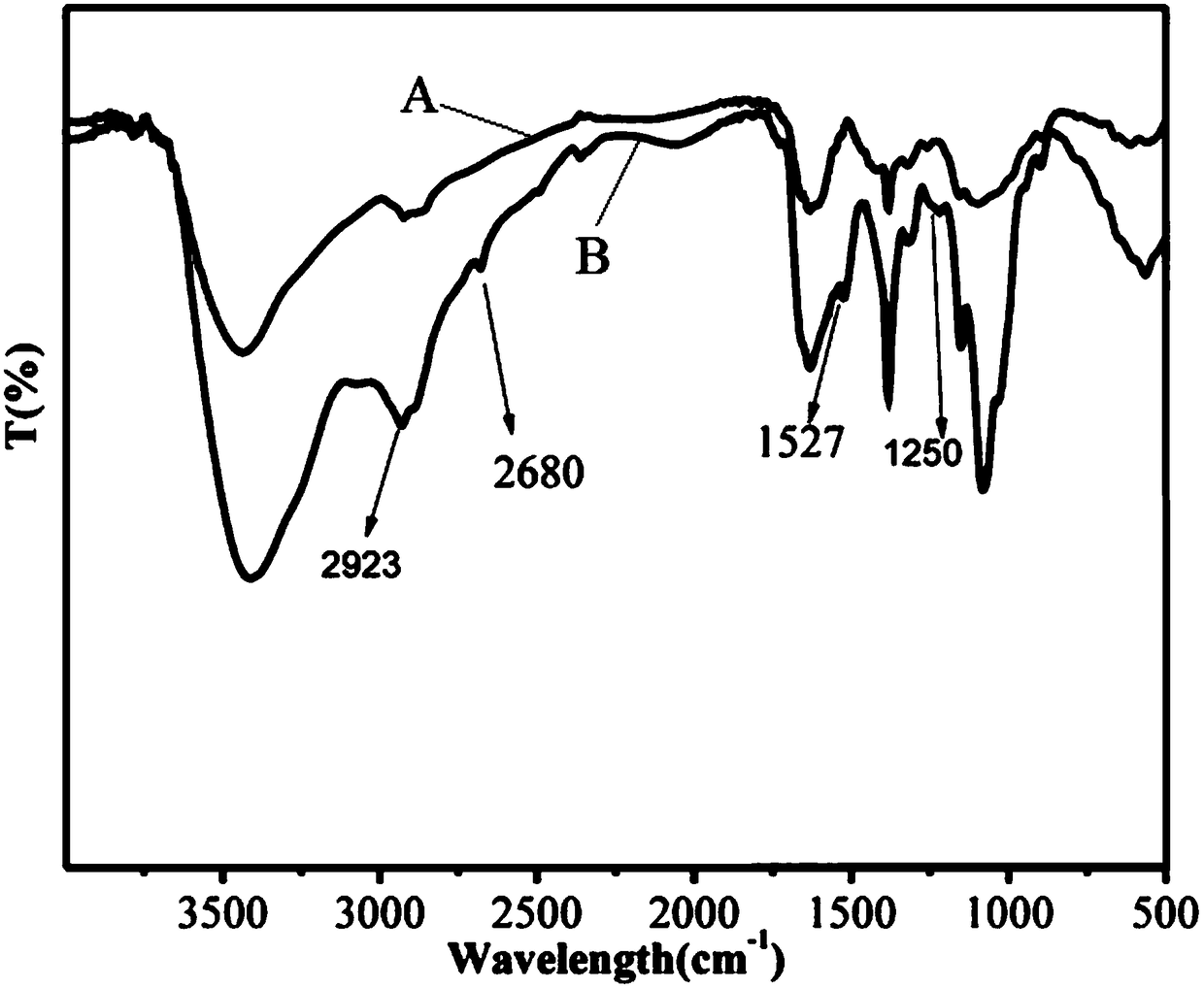

[0042] The preparation of embodiment 1 amphiphilic chitosan

[0043] (1) Get the chitosan that viscosity is not more than 200mPa.s, be configured into the chitosan aqueous solution that mass concentration is 1.0% with the glacial acetic acid aqueous solution of 1.0% with mass concentration; Get stearic acid, be configured with dehydrated alcohol into mass concentration Concentration is the ethanol solution of stearic acid of 2.0%;

[0044] (2) getting 1kg of the above-mentioned mass concentration of 1.0% chitosan aqueous solution and 1kg of the above-mentioned mass concentration of 2.0% stearic acid ethanol solution, mix, stir and add 10g of 1-ethyl-3-(3-di Methylaminopropyl) carbodiimide hydrochloride, at a temperature of 80°C and a stirring speed of 3000rpm, stirring and reacting for 3h, grafting stearic acid into chitosan molecules as a hydrophobic group to obtain hard Stearic acid grafted chitosan with fatty acid hydrophobic group grafting ratio of 5%;

[0045] (3) Step ...

Embodiment 2

[0048] The preparation of embodiment 2 amphiphilic chitosan

[0049] (1) Get the chitosan that viscosity is not more than 200mPa.s, be configured into the chitosan aqueous solution that mass concentration is 3.0% with the glacial acetic acid aqueous solution of 1.0% with mass concentration; Get stearic acid, be configured with dehydrated alcohol into mass concentration Concentration is the ethanol solution of stearic acid of 5.0%;

[0050] (2) getting 1kg of the above-mentioned mass concentration of 3.0% chitosan aqueous solution and 1kg of the above-mentioned mass concentration of 5.0% stearic acid ethanol solution, mix, stir and add 100g of 1-ethyl-3-(3-di Methylaminopropyl) carbodiimide hydrochloride, at a temperature of 80°C and a stirring speed of 1000rpm, stirring and reacting for 5h, grafting stearic acid into the chitosan molecule as a hydrophobic group to obtain hard Stearic acid grafted chitosan with fatty acid hydrophobic group grafting ratio of 20%;

[0051] (3) ...

Embodiment 3

[0052] The preparation of embodiment 3 amphiphilic chitosan

[0053] (1) Get the chitosan that viscosity is not more than 200mPa.s, be configured into the chitosan aqueous solution that mass concentration is 2.0% with the glacial acetic acid aqueous solution of 1.0% with mass concentration; Get stearic acid, be configured with dehydrated alcohol into mass concentration Concentration is the stearic acid ethanol solution of 3.0%;

[0054] (2) get 1kg above-mentioned mass concentration and be that the chitosan aqueous solution of 2.0% and 1kg above-mentioned mass concentration are the stearic acid ethanol solution of 3.0%, mix, add 80g of 1-ethyl-3-(3-di Methylaminopropyl) carbodiimide hydrochloride, at a temperature of 80°C and a stirring speed of 2000rpm, stirring and reacting for 4h, grafting stearic acid into the chitosan molecule as a hydrophobic group to obtain hard Stearic acid grafted chitosan with fatty acid hydrophobic group grafting ratio of 10%;

[0055] (3) Add 140...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com