An analysis method of the influence of ultrasonic shock treatment on the residual stress of a metal component formed by laser selective melting

A laser selective melting and ultrasonic impact technology, applied in the field of additive manufacturing, can solve the problem of not considering initial stress and deformation, and achieve the effect of optimizing impact process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

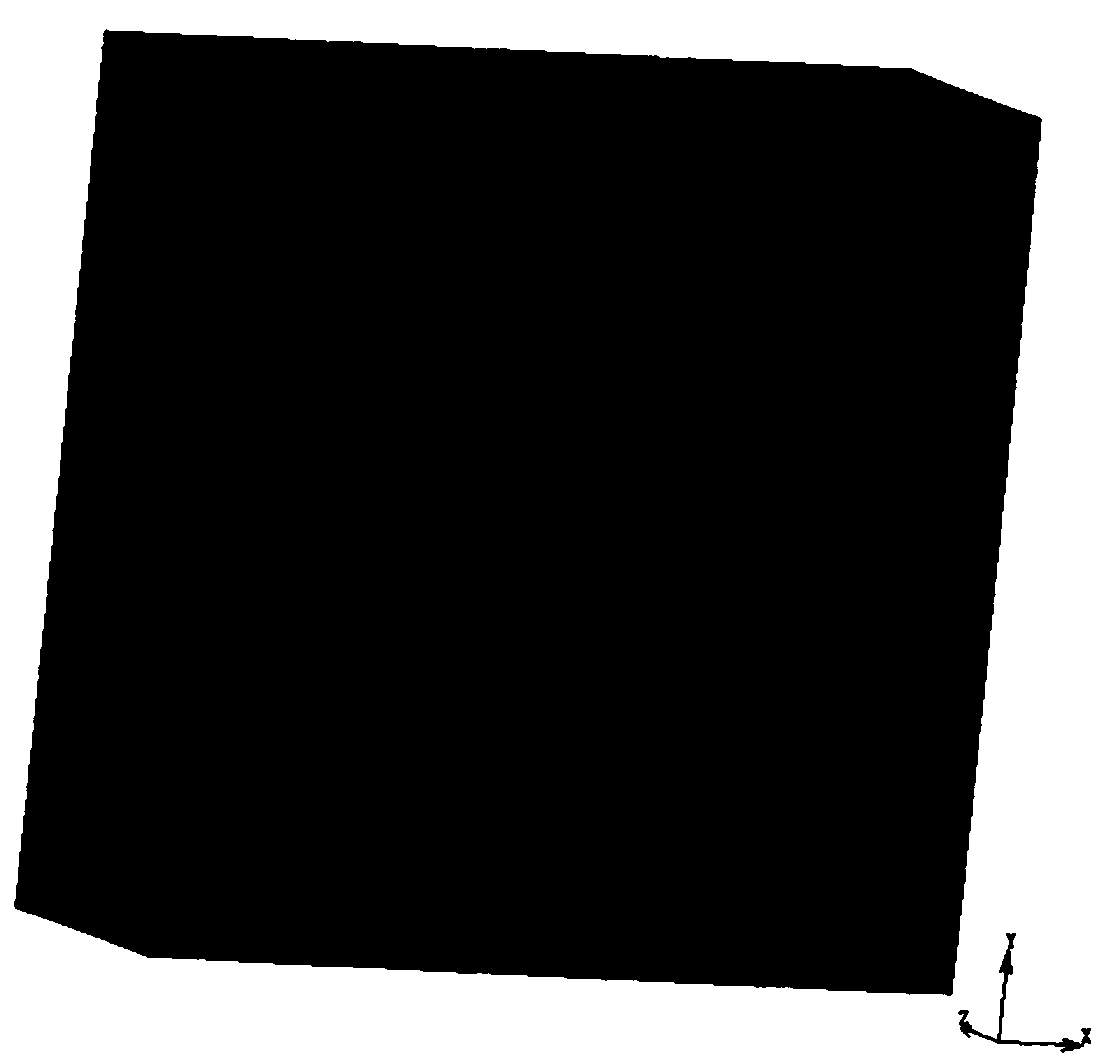

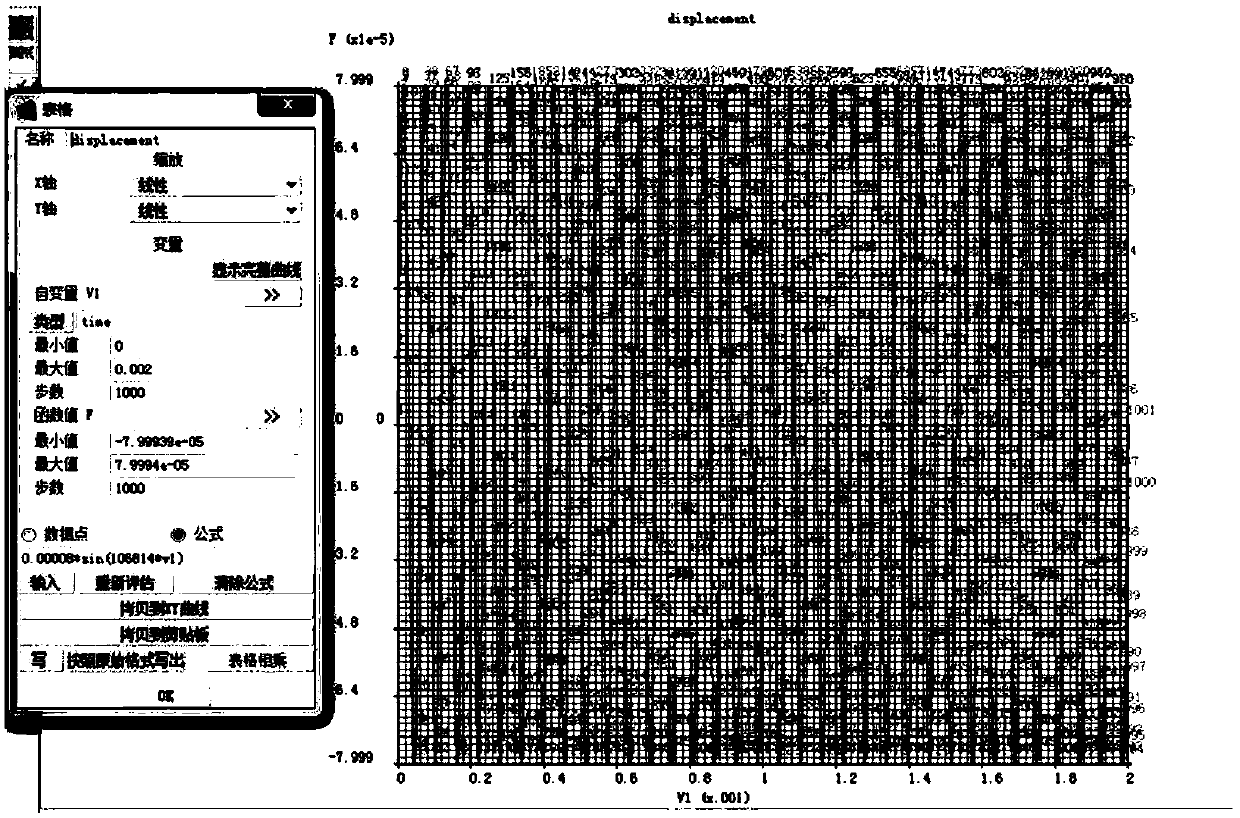

[0027] figure 1 is the finite element mesh division diagram of the impacted member; figure 2 The overall assembly diagram after meshing the punch, impact pin and impacted member; image 3 is the displacement load curve loaded on the punch; Figure 4 It is the lateral direction displacement diagram cut along the centerline longitudinal section of the component after laser selective melting and forming; Figure 5 is the transverse stress distribution after the component is cut along the longitudinal section of the centerline after selective laser melting; Figure 6 is the transverse stress distribution after the impact treatment is cut along the longitudinal section of the centerline; Figure 7 After the impact treatment, the transverse displacement distribution of the component is cut along the longitudinal section of the center line.

[0028] The first is the sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com