Polymer drag reducer swelling treatment method for shortening onset time of drag reducer

A technology of onset time and treatment method, applied in the production of bulk chemicals, pipeline systems, mechanical equipment, etc., can solve the problems of difficulty in injecting drag reducing agents, reducing drag reducing efficiency, and decreasing the dissolution rate of drag reducing agent particles. Quickly reduce drag and increase the effect, shorten the swelling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

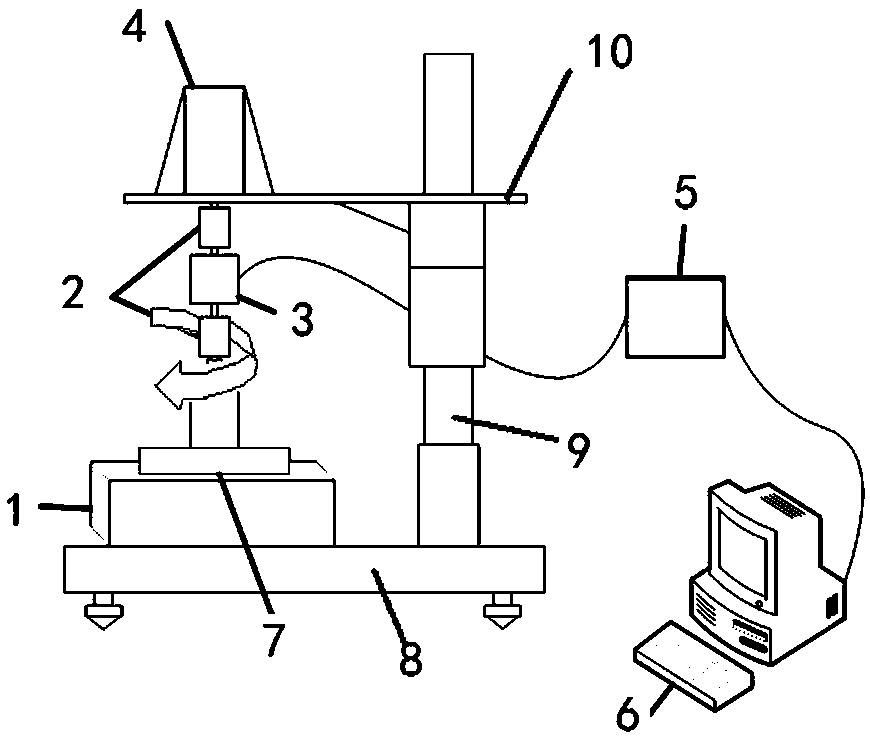

Image

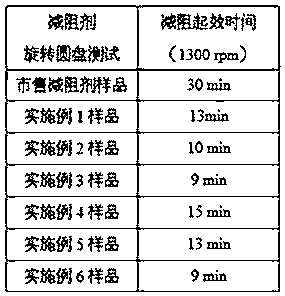

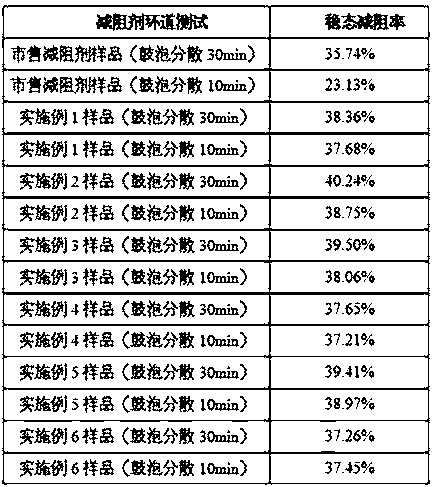

Examples

Embodiment 1

[0033] Embodiment 1: A kind of polymer drag reducer particle swelling treatment method for shortening the onset time of drag reducer mentioned in the present invention, its preparation method is as follows:

[0034] First, cut the dry bulk drag-reducing polymer solid into 5 cm square pieces, weigh 1 kg, place it in a pressure-resistant and heat-retaining reactor and seal it; then fill the reactor with CO 2 , to reach 6.0MPa, control the temperature at 10 ℃ within 30 minutes, and then refill CO 2 To the set pressure of 7.5MPa (CO at 10°C 2 Critical pressure 7.2MPa), at this time the CO in the kettle 2 It is supercritical and kept for 12 h; after the polymer swells, the CO in the kettle is removed 2 And take out the sample, weigh the weight of the marked sample within 2 minutes to be 1.123 kg; put the swollen drag-reducing polymer into the freezing bucket, then fill it with liquid nitrogen to submerge the polymer, and keep it for 30 minutes. After the liquid nitrogen evaporate...

Embodiment 2

[0035] Embodiment 2: A kind of polymer drag reducer particle swelling treatment method for shortening the onset time of the drag reducer mentioned in the present invention, its preparation method is as follows:

[0036] First, cut the dry bulk drag-reducing polymer solid into 5 cm square pieces, weigh 1 kg, place it in a pressure-resistant and heat-retaining reactor and seal it; then fill the reactor with CO 2 , reach 2.0MPa, control the temperature at -10 ℃ within 30 minutes, and then refill CO 2 To set pressure 4.0MPa (CO at 10°C 2 Critical pressure 4.5MPa), at this time the CO in the kettle 2 It is supercritical and kept for 4 h; after the polymer swells, the CO in the kettle is removed 2 And take out the sample, weigh the weight of the marked sample to be 1.086kg within 2 minutes; put the swollen drag-reducing polymer into the freezing bucket, then fill it with liquid nitrogen to submerge the polymer, and keep it for 10 minutes. After the liquid nitrogen evaporates, Then ...

Embodiment 3

[0037] Embodiment 3: A kind of polymer drag reducer particle swelling treatment method for shortening the onset time of drag reducer mentioned in the present invention, its preparation method is as follows:

[0038] First, cut the dry massive drag-reducing polymer solid into small pieces of 5 cm square, weigh 1 kg, place it in a pressure-resistant and heat-retaining reactor and seal it; then fill the reactor with methanol to reach 0.1 MPa, and then Control the temperature at 0°C within 30 minutes, and then refill methanol to the set pressure of 0.1MPa (the critical pressure of methanol at 10°C is 0.003MPa). At this time, the methanol in the kettle is supercritical and kept for 4 hours; After swelling, remove the methanol in the kettle (pay attention to the recovery of methanol) and take out the sample, weigh the marked sample weight within 2 minutes to 1.026kg; put the swollen drag-reducing polymer into a freezing bucket, and then fill it with liquid nitrogen to Submerge the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com