Novel coper paper pulping method

A technology for copying paper and pulping, which is applied to pulp beating methods, papermaking, and papermaking machines, etc., can solve problems such as affecting the production efficiency of papermaking machines, large damage to the grinding discs of the grinding machine, and unstable slurry concentration, so as to reduce the beating time, The effect of improving production efficiency and shortening adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

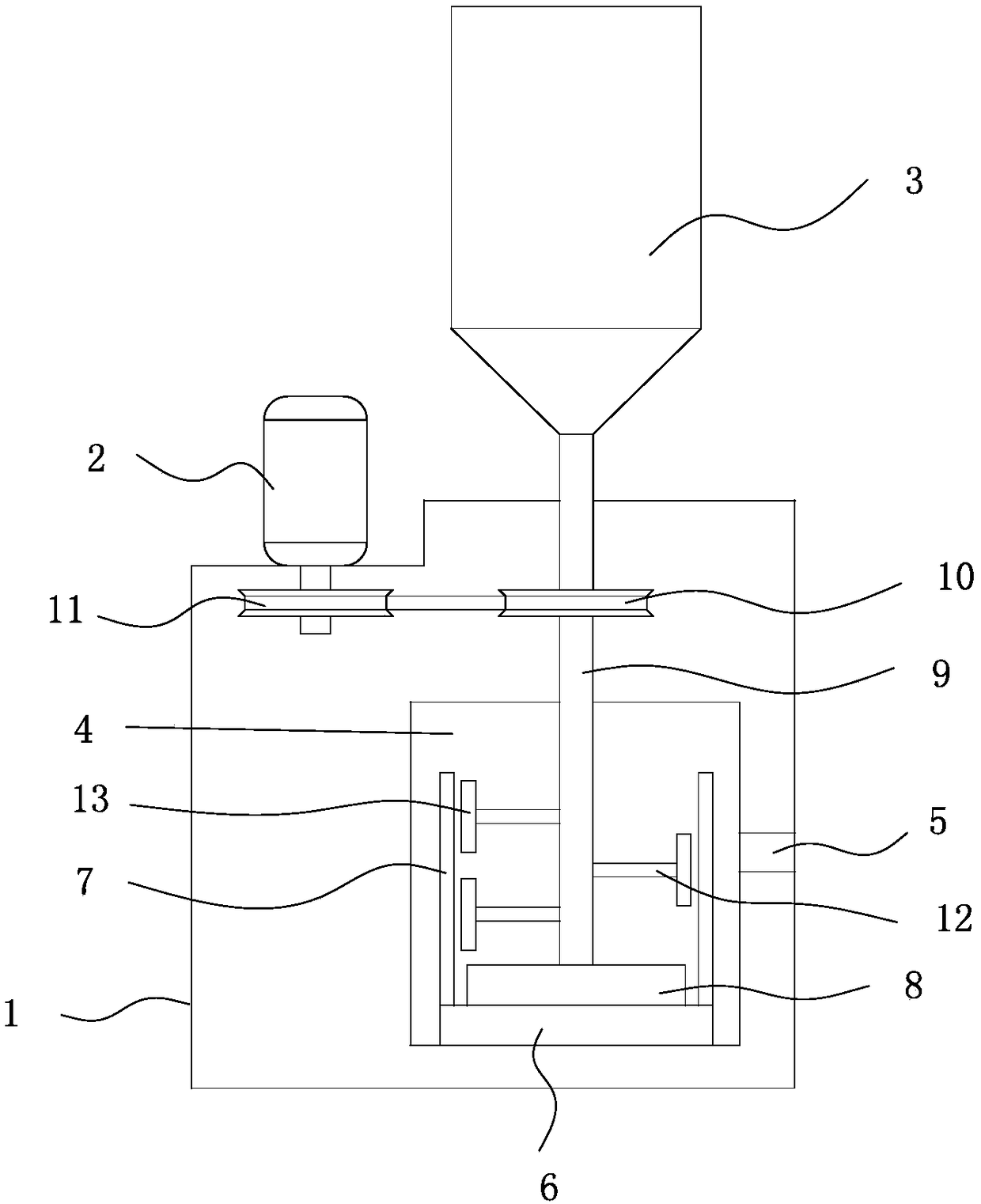

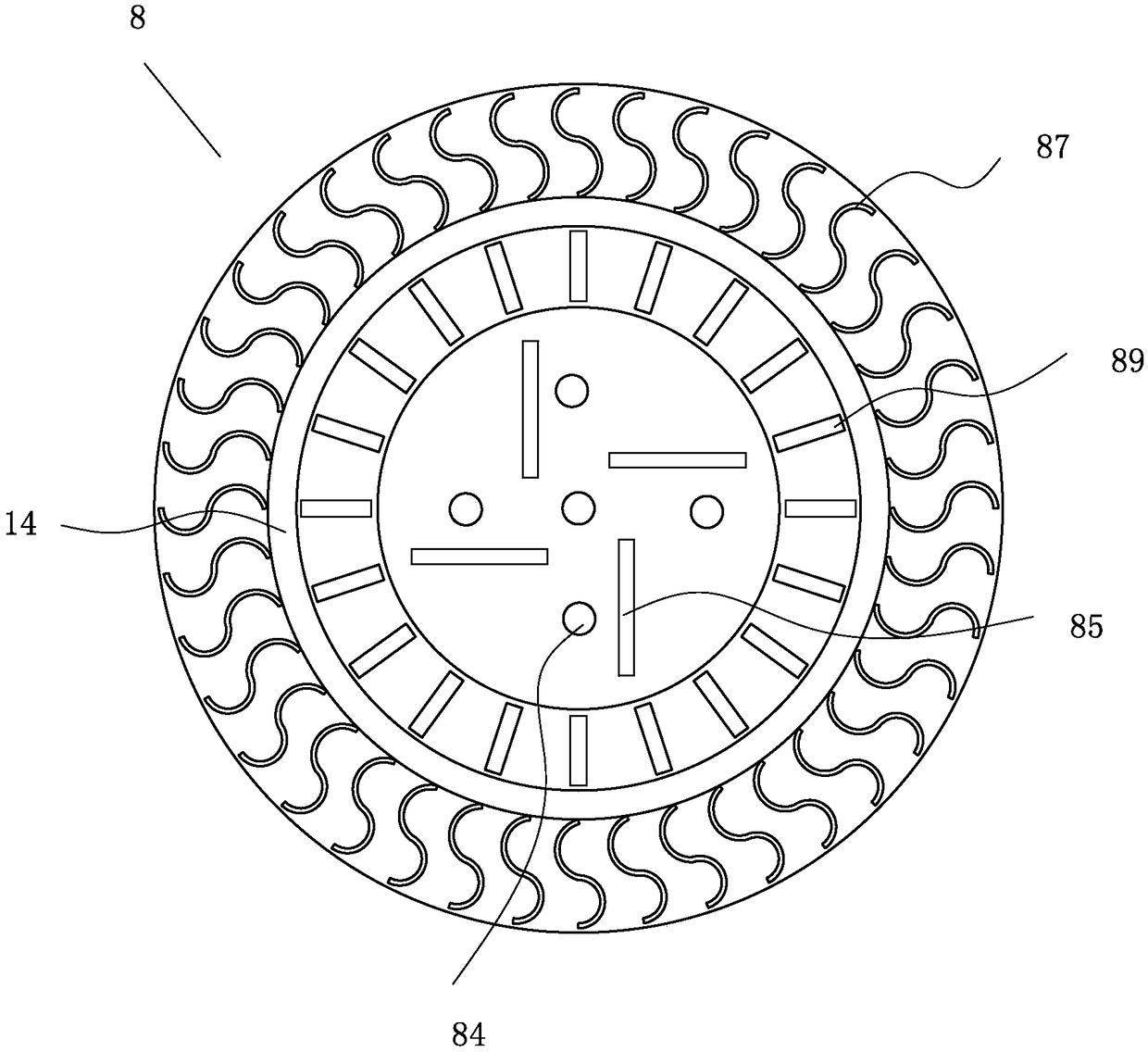

[0026] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0027] Embodiments of the invention are:

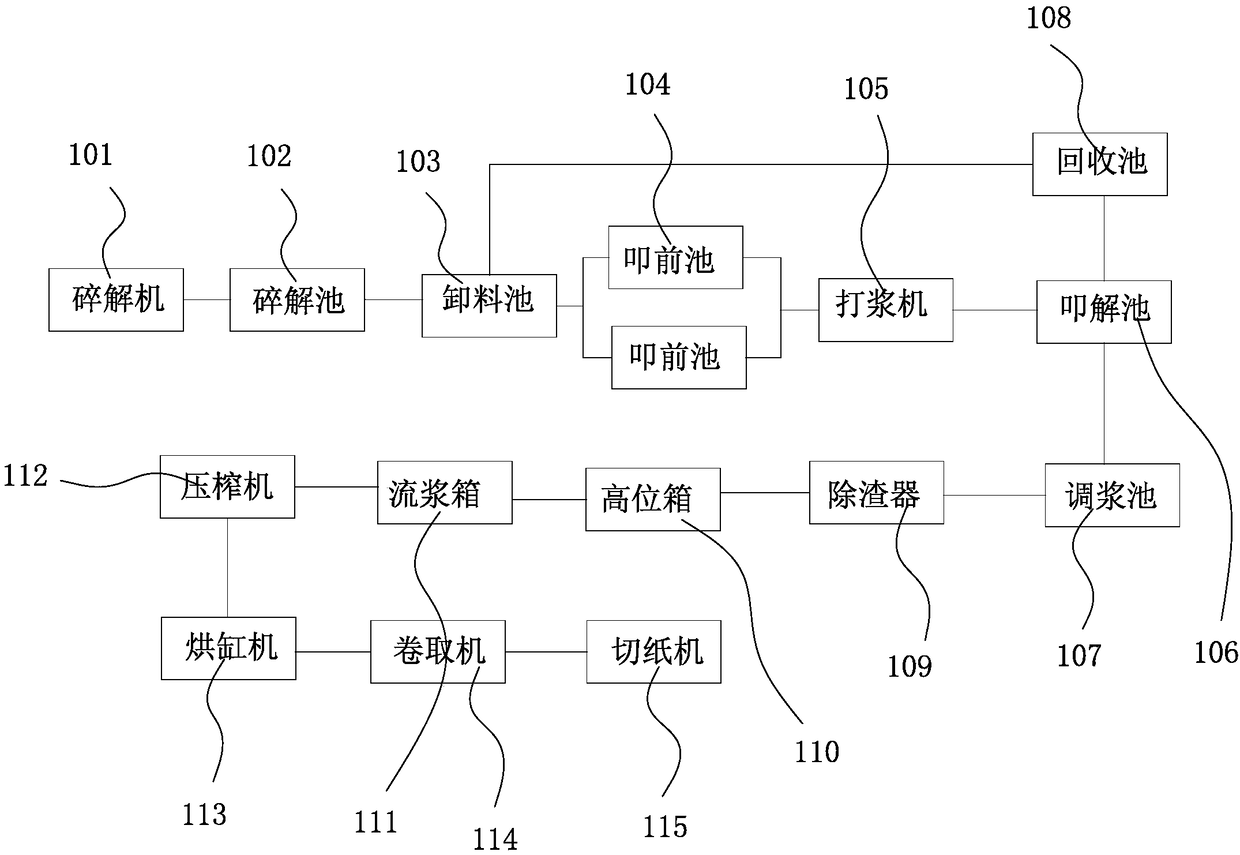

[0028] refer to figure 1 , a new copy paper pulping method, including a disintegrator 101, a disintegration tank 102, a discharge tank 103, two knocking pools 104, a beater 105, a knocking tank 106, a mixing tank 107, a recovery tank 108, Slag remover 109, head box 110, headbox 111, press machine 112, dryer machine 113, coiler 114, paper cutter 115, the pulping method is as follows:

[0029] 1) The waste paper is disintegrated by the disintegrator 101 to form a dry slurry and flows into the disintegration tank 102;

[0030] 2) Take 5 parts of dry slurry from the disintegration tank 102 and put it into the discharge tank 103, and simultaneously get 95 parts of water and add it to the discharge tank 103 for dilution, and prepare a slurry with a concentration of 5%;

[0031] 3) The slurry with a stable conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com