Carbon nanotube/polypyrrole composite fiber and its preparation method and its application in transistor sensors

A carbon nanotube and composite fiber technology, applied in the field of biosensors, can solve the problems of narrow detection range and high production cost of flexible lactic acid sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

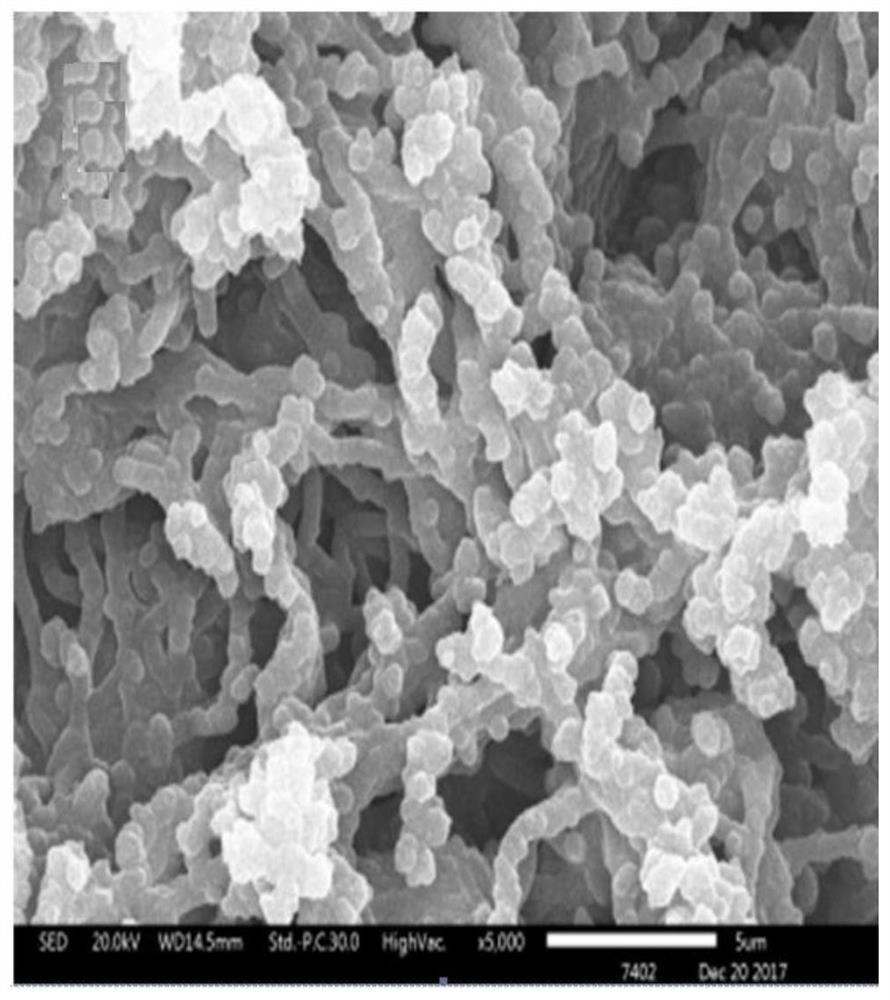

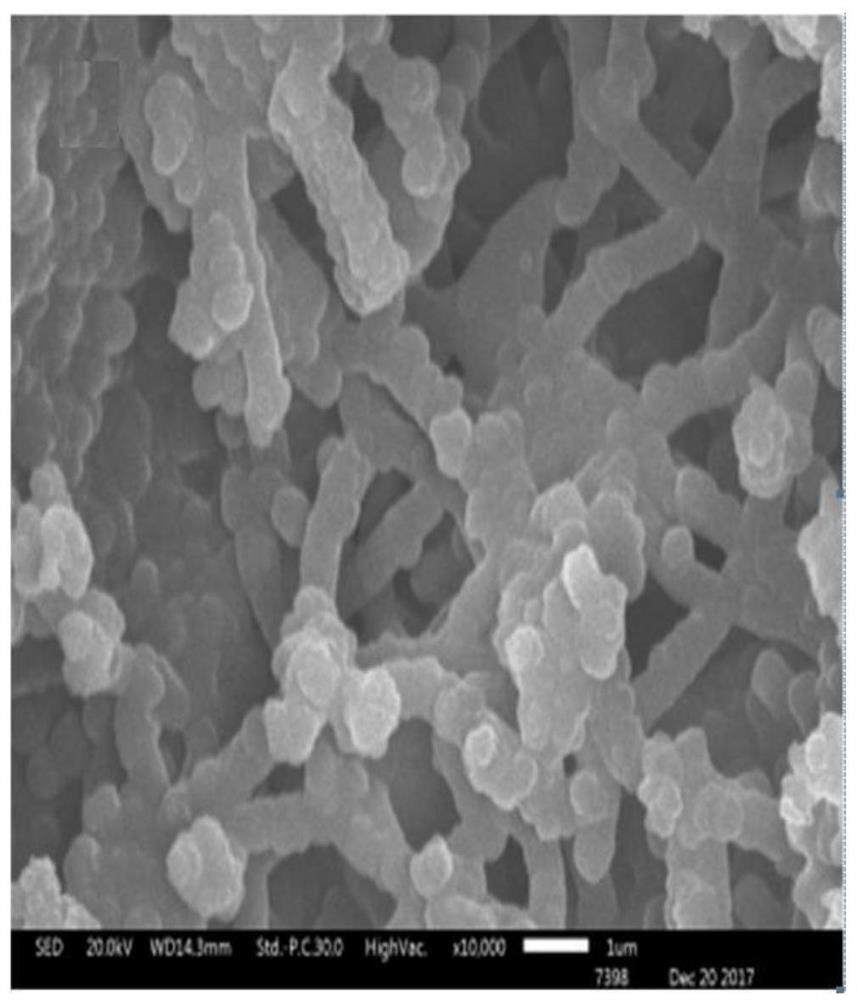

[0078] This embodiment provides a method for preparing a carbon nanotube / polypyrrole composite fiber-based transistor sensor, which includes the following steps:

[0079] 1) Configure carbon nanotube dispersion: take the mass of 1g carbon nanotubes, 1g sodium dodecyl sulfate and 100g deionized water, respectively, and ultrasonically treat for 1 hour after mixing to obtain carbon nanotube dispersion;

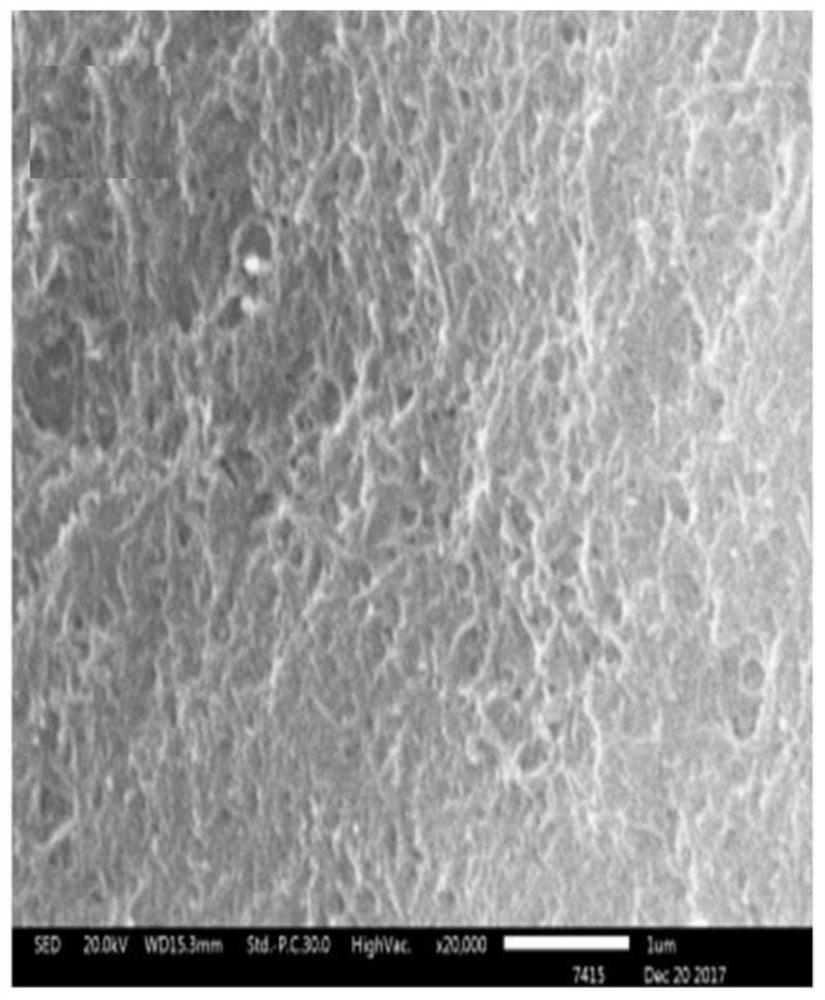

[0080] 2) Preparation of flexible fibers coated with carbon nanotube layers: take the PA6 nylon fibers whose surfaces have been ultrasonically cleaned with ethanol, and place them in the carbon nanotube dispersion in step 1) for repeated immersion for 4 h, take out, wash with water, and dry. A flexible fiber coated with a carbon nanotube layer is obtained;

[0081] 3) Configure mixed solution A: take 0.15 g of anthraquinone-2-sulfonic acid sodium salt, and dissolve 1.8 g of pyrrole monomer into deionized water to obtain 150 mL of mixed solution A;

[0082] 4) configure mixed sol...

Embodiment 2

[0091] This embodiment provides a method for preparing a carbon nanotube / polypyrrole composite fiber-based transistor sensor, which includes the following steps:

[0092] 1) Configure carbon nanotube dispersion: take the mass of 1g carbon nanotubes, 1g sodium dodecyl sulfate and 100g deionized water, respectively, and ultrasonically treat for 1 hour after mixing to obtain carbon nanotube dispersion;

[0093] 2) Preparation of flexible fibers coated with carbon nanotube layers: take the silk fibers whose surfaces have been ultrasonically cleaned with ethanol, place them in the carbon nanotube dispersion in step 1) and soak them for 4 hours, take out, wash with water, and dry to obtain Flexible fibers coated with carbon nanotube layers;

[0094] 3) Configure mixed solution A: take 0.15 g of anthraquinone-2-sulfonic acid sodium salt and 1.8 g of pyrrole monomer in deionized water to obtain 150 mL of mixed solution A;

[0095] 4) configure mixed solution B: get 30g of 9-hydrated ...

Embodiment 3

[0104] This embodiment provides a method for preparing a carbon nanotube / polypyrrole composite fiber-based transistor sensor, which includes the following steps:

[0105] 1) Configure carbon nanotube dispersion: take the mass of 1g carbon nanotubes, 1g sodium dodecyl sulfate and 100g deionized water, respectively, and ultrasonically treat for 1 hour after mixing to obtain carbon nanotube dispersion;

[0106] 2) Preparation of flexible fibers coated with carbon nanotube layers: take polyester fibers whose surfaces have been ultrasonically cleaned with ethanol, soak them in the carbon nanotube dispersion in step 1) for 4 hours, take out, wash with water, and dry to obtain Flexible fibers coated with carbon nanotube layers;

[0107] 3) Configure mixed solution A: take 0.15 g of anthraquinone-2-sulfonic acid sodium salt and 1.8 g of pyrrole monomer in deionized water to obtain 150 mL of mixed solution A;

[0108] 4) configure mixed solution B: get 30g of 9-hydrated ferric nitrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com