Environment-friendly synthetic ester air compressor oil and preparation method thereof

An air compressor oil, synthetic ester technology, applied in the petroleum industry, lubricating composition, fatty acid chemical modification and other directions, can solve the problems of poor high temperature oxidation stability, short service life, high operating cost, and achieve good high temperature resistance. The effect of oxidation performance, cost saving, high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

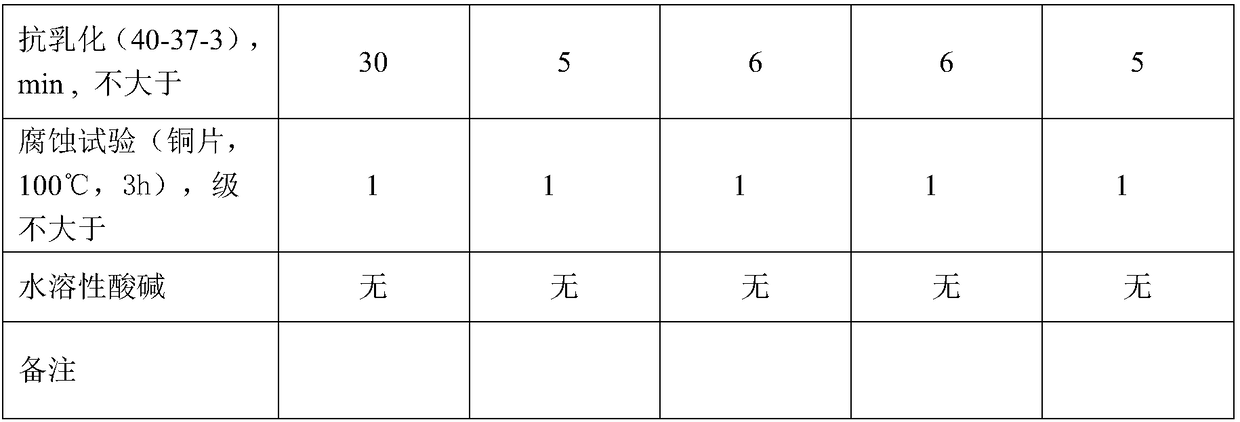

Embodiment 1

[0021] The invention provides an air compressor oil, which is composed of modified vegetable oil, synthetic ester, high temperature antioxidant, antirust agent, antiwear agent, pour point depressant and antifoaming agent.

[0022] The mass percent of the modified vegetable oil in the air compressor oil is 46.995%, and the modified vegetable oil is composed of rapeseed oil and peanut oil. The mass percent of the rapeseed oil in the vegetable oil is 50%, and the mass percent of the peanut oil in the vegetable oil is 50%. The reaction pressure is 8MPa, the reaction temperature is 300°C, the total space velocity of oil feed is 0.8 / h, the reaction hydrogen to oil volume ratio is 700, and the catalyst in the hydrofinishing process is Ni-W / AL 2 o 3 , followed by atmospheric and vacuum distillation. The vacuum distillation process is a residual pressure of 1-65 mmHg, and the atmospheric distillate oil at 350-450° C. is cut to obtain hydrogenated vegetable oil. Then earlier use the N...

Embodiment 2

[0030] The invention provides an air compressor oil, which is composed of modified vegetable oil, synthetic ester, high temperature antioxidant, antirust agent, antiwear agent, pour point depressant and antifoaming agent.

[0031] The mass percent of the modified vegetable oil in the air compressor oil is 49.994%, and the modified vegetable oil is mixed with rapeseed oil, peanut oil and soybean oil. The mass percent of the rapeseed oil in the vegetable oil is 40%, the mass percent of the peanut oil in the vegetable oil is 40%, and the mass percent of the soybean oil in the vegetable oil 20%, first carry out hydrofinishing, the reaction pressure of the reactor in the hydrofinishing process is 10MPa, the reaction temperature is 350°C, the total space velocity of the oil feed is 0.6 / h, and the reaction hydrogen oil volume ratio is 650. The catalyst in the hydrofining process is Ni-Mo-Co / AL 2 o 3 , followed by atmospheric and vacuum distillation. The vacuum distillation process ...

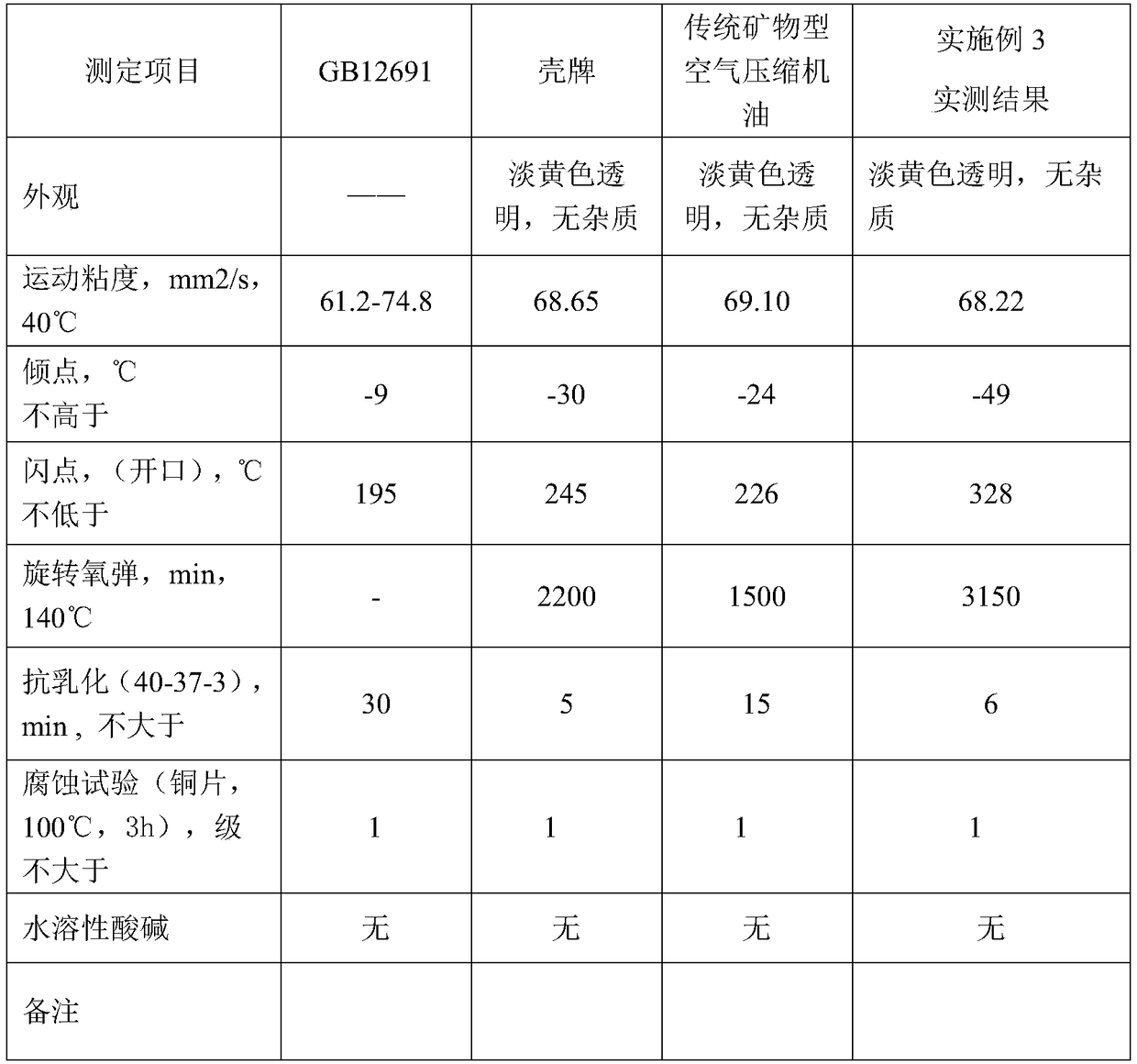

Embodiment 3

[0040] The invention provides an air compressor oil, which is composed of modified vegetable oil, synthetic ester, high temperature antioxidant, antirust agent, antiwear agent, pour point depressant and antifoaming agent.

[0041] The mass percent of the modified vegetable oil in the air compressor oil is 45.993%, and the modified vegetable oil is mixed with rapeseed oil, peanut oil, soybean oil and olive oil. The mass percent of the rapeseed oil in the vegetable oil is 25%, the mass percent of the peanut oil in the vegetable oil is 25%, and the mass percent of the soybean oil in the vegetable oil is 25%, and the mass percentage of the olive oil in the vegetable oil is 25%. Hydrofining is carried out first. During the hydrofining process, the reaction pressure of the reactor is 12MPa, the reaction temperature is 400°C, the total space velocity of the oil feed is 0.7 / h, and the reaction hydrogen oil volume ratio is 750. The hydrofining process described above The catalyst in i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com