System for transferring silicon single crystal rods

A single crystal silicon rod and detection unit technology, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of increasing labor intensity of operators, chipping of single crystal silicon rods, increasing losses, etc., and achieve labor saving Cost and labor intensity, enhanced stability, and reduced chipping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

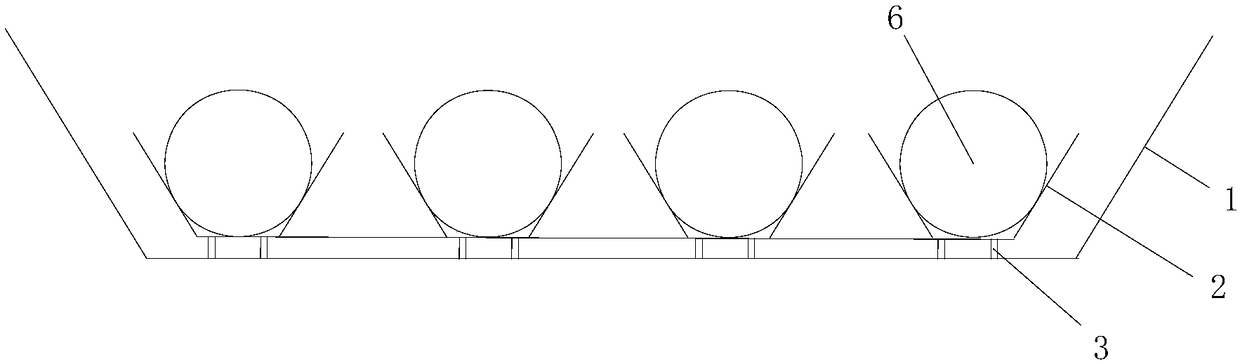

[0037] like Figure 1 to Figure 5 As shown, a monocrystalline silicon rod transfer system includes: a supporting unit, the supporting unit is used to support at least one single crystal silicon rod 6; a lifting unit, the lifting unit is used to lift the The supporting unit is hoisted from the first position to the second position; and the clamping and conveying unit is used to clamp the single crystal silicon rod 6 in the supporting unit and transport it to the third position .

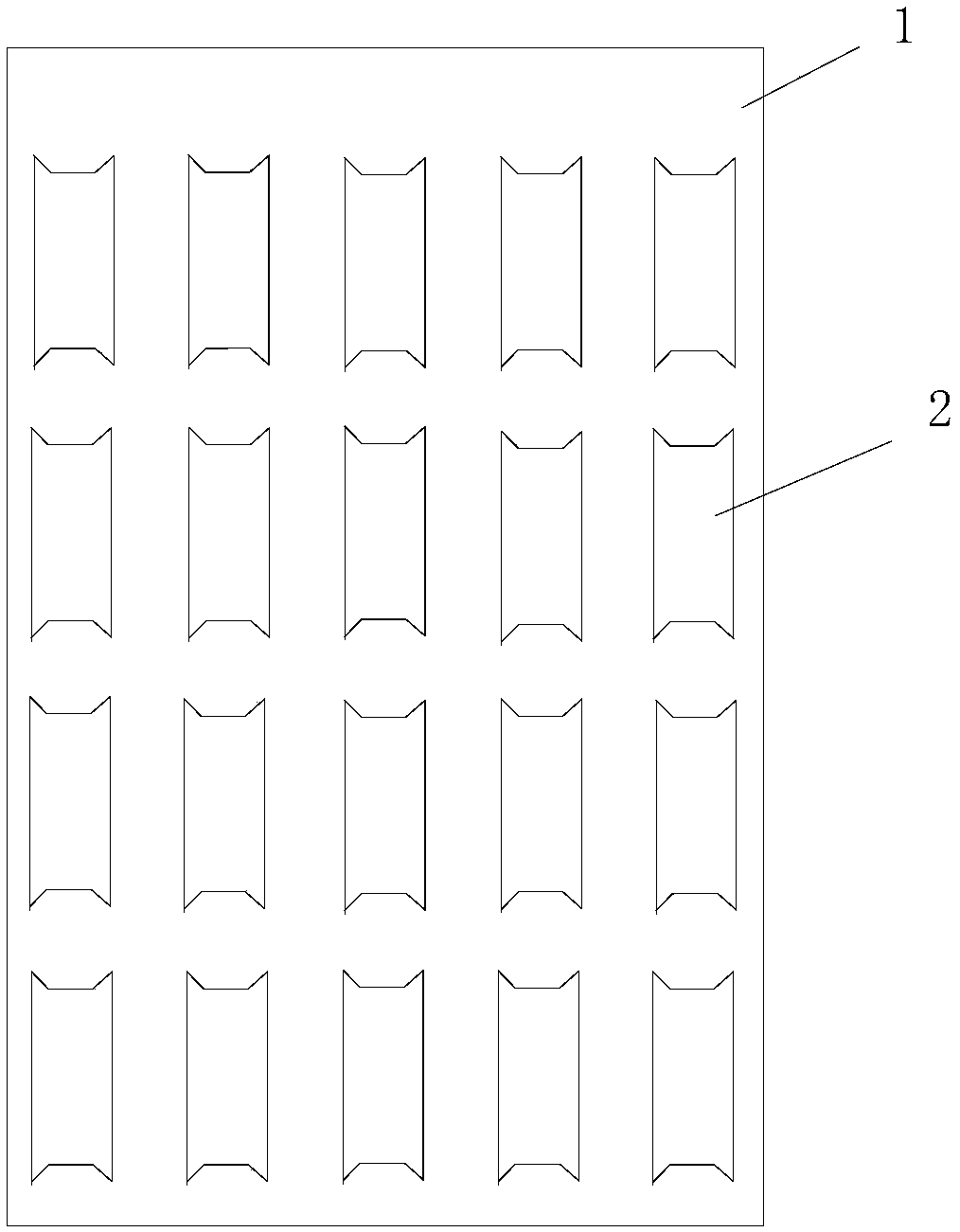

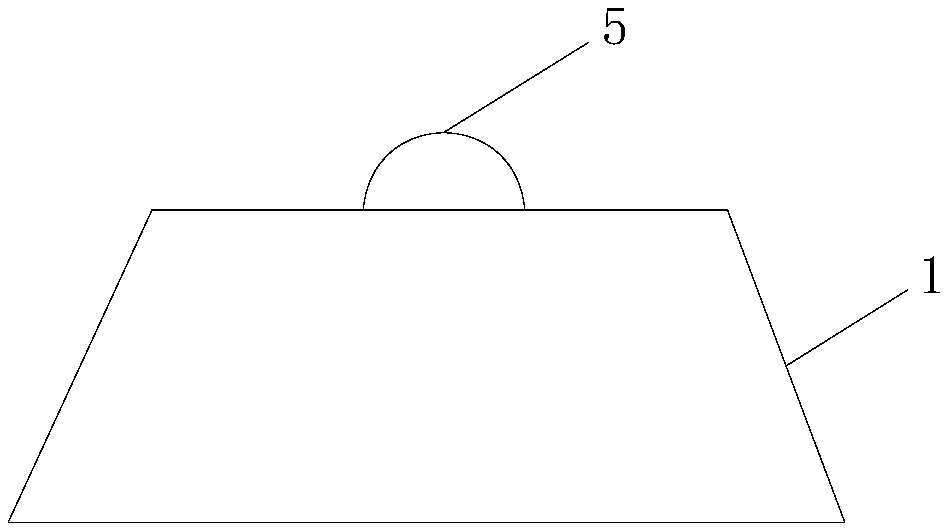

[0038] The supporting unit includes a box body 1 with an open top, and at least one bracket 2 is arranged in the box body 1 . In order to improve the transfer efficiency of the single crystal silicon rods 6 , preferably, a plurality of the holders 2 are arranged in the box 1 , each of the holders 2 is in the shape of an inverted trapezoidal groove.

[0039] In order to adapt to the transfer of monocrystalline silicon rods 6 of different lengths and diameters, the application has multiple sets of sup...

Embodiment 2

[0060] The structure of this embodiment and embodiment 1 is basically the same as before, the difference is:

[0061] Different from the manner in which the lifting unit and the supporting unit are hooked and connected through hooks and lugs in Embodiment 1, the lifting unit and the supporting unit in this application are connected through electromagnetic adsorption.

[0062] Specifically, a plurality of iron blocks can be respectively arranged on both sides of the top of the box, and the lifting unit includes electromagnets with the same number as the iron blocks, and when the electromagnets are energized, a strong adsorption force is generated to complete the pairing. For the hoisting of most boxes, when the box moves to the second position, the electromagnet is powered off, and the adsorption force disappears, thereby realizing the separation of the lifting unit from the supporting unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com