Stirring barrel and method for preparing environmentally-friendly cutting oil by using stirring barrel

A technology of mixing barrels and cutting oil, which is applied to mixers with rotary mixing devices, chemical instruments and methods, and dissolution, etc., can solve problems such as poor mixing effect, and achieve the effects of improving mixing effect, stirring strength and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

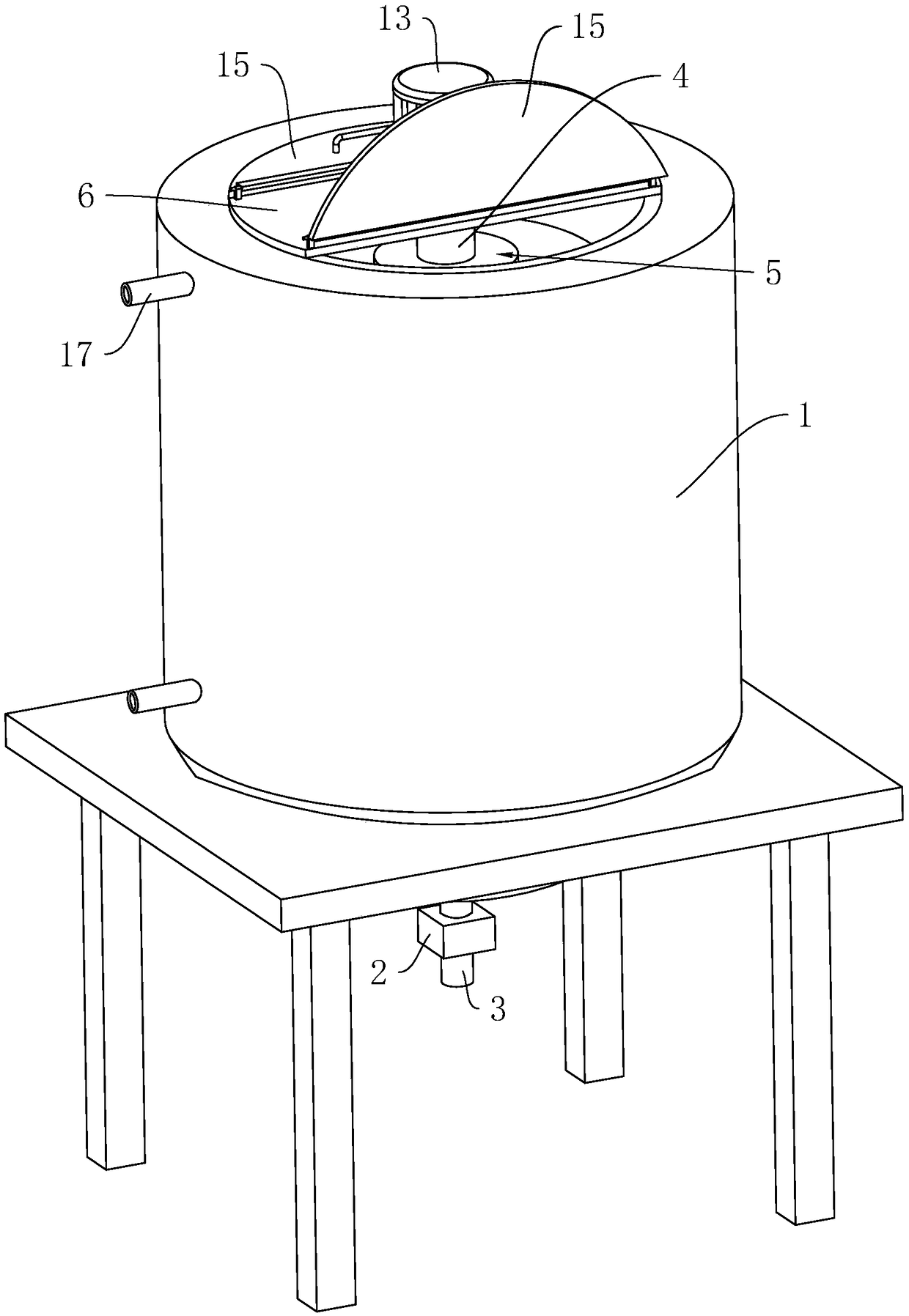

[0047] Embodiment 1: a kind of mixing bucket, as figure 1 As shown, it includes a cylinder-shaped barrel 1 with an open upper end. At the same time, a discharge pipe 3 is installed at the lower end of the above-mentioned barrel 1, and a valve 2 is installed on the above-mentioned discharge pipe 3. The operator can pass through the above-mentioned valve. 2 Manually open and close the discharge pipe 3, so that it is convenient for the operator to extract the cutting oil in the barrel body 1.

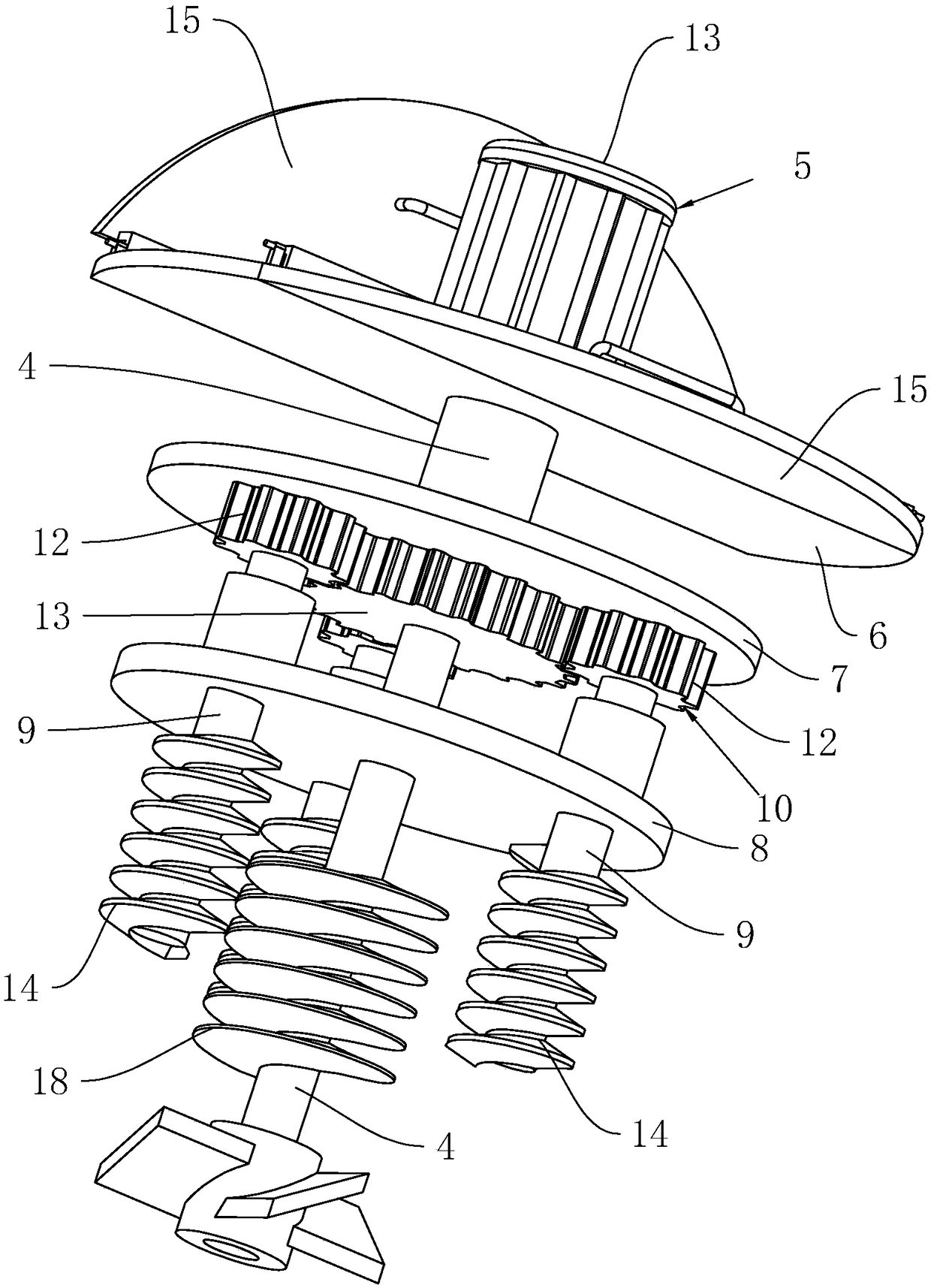

[0048] In order to improve the mixing effect of cutting oil, such as figure 1 and figure 2 As shown, a mounting base 6 is provided at the center of the upper end of the barrel body 1, and a cylindrical rotating shaft 4 is connected to its inner bearing. Wherein, the lower end of the rotating shaft 4 extends into the bucket body 1 and is provided with a stirring assembly 5 . Above-mentioned agitating assembly 5 comprises the shaft sleeve disc 7 welded on the mount 6, the fixed disc 8 we...

Embodiment 2

[0054] Embodiment 2: a kind of method that uses the preparation environment-friendly cutting oil of mixing tank, and above-mentioned mixing tank is the mixing tank stated in embodiment 1, and it comprises following operation steps:

[0055] Step S1 , filling a large amount of protective gas from one side of the barrel body 1 to exhaust the air in the barrel body 1 .

[0056] Step S2, while filling the protective gas, add the raw materials for preparing environmentally friendly cutting oil into the barrel body 1 sequentially from the opening, then stop the inflation and close the cover body 15, seal and stir evenly.

[0057] Wherein, environment-friendly cutting oil, according to the components in parts by weight, includes:

[0058] Base oil 100 parts

[0059] Fatty acid methyl ester 25-30 parts

[0060] Nano titanium dioxide 5-8 parts

[0061] Alcohol liquid 15-32 parts

[0062] 8-10 parts of triethanolamine

[0063] 8-10 parts of boric acid.

[0064] At the same time, t...

Embodiment 3

[0068] Embodiment 3: A method for preparing environmentally friendly cutting oil using a mixing tank, the above mixing tank is the mixing tank stated in Example 1, and the difference from Example 2 is that the environmentally friendly cutting oil also includes extreme pressure wear-resistant additives ZDDP. Among them, the main component of the extreme pressure wear-resistant additive ZDDP is zinc dialkyldithiophosphate, and the molecular formula is C 28 h 6 0O 4 P 2 S 4 Zn, it is a compound synthesized from alcohol, phosphorus pentasulfide and zinc salt. The extreme pressure and wear-resistant additive ZDDP can prevent the oxidation of cutting oil and reduce the wear and tear of machinery, thereby improving the anti-oxidation and anti-oxidation properties of environmentally friendly cutting oil. Anti-wear effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com