Environment-friendly air purification device

An air purification device and environmental protection technology, applied in the field of air purification, can solve problems such as accumulation of impurities, difficulty in purification, failure to meet environmental protection requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

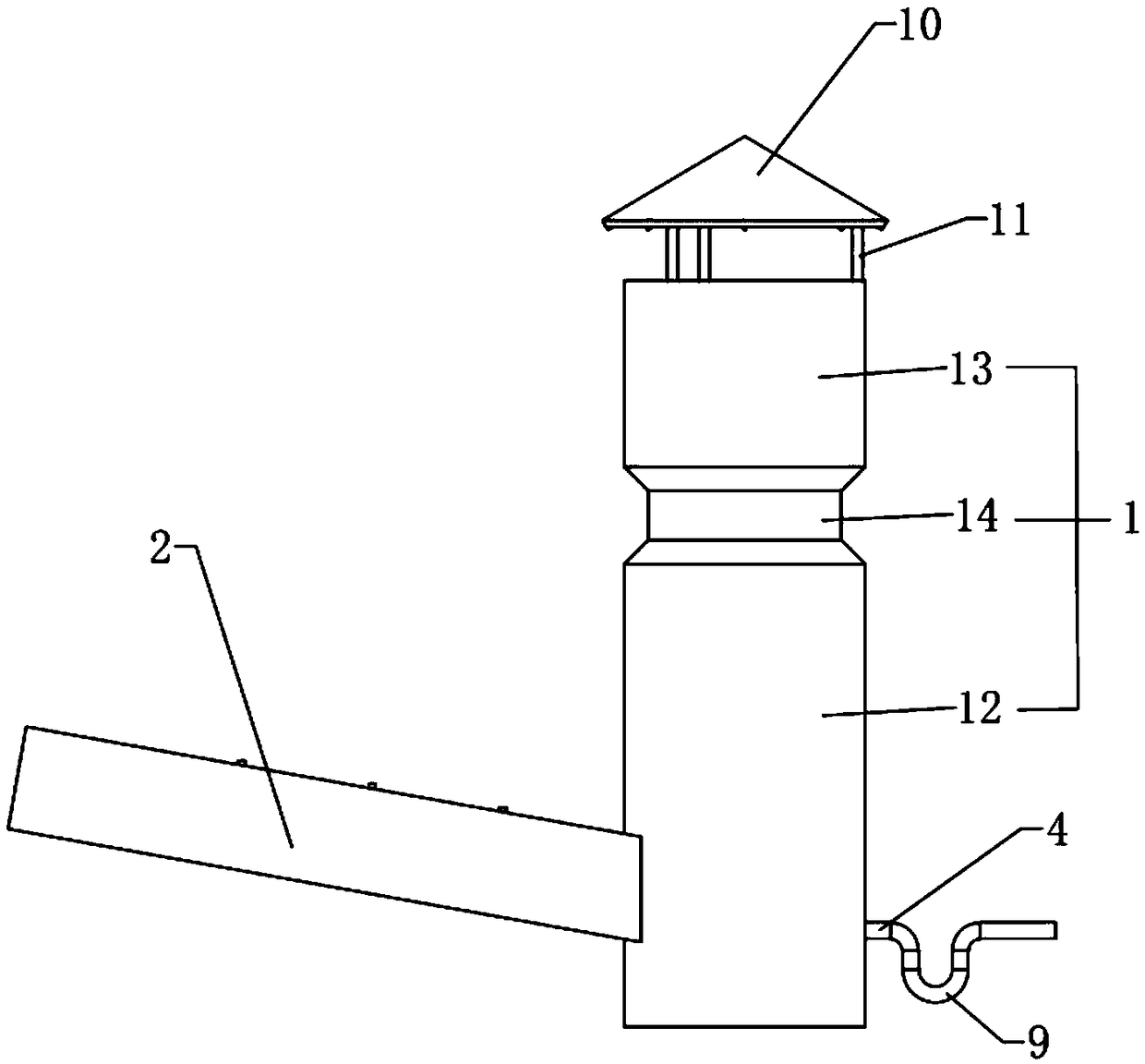

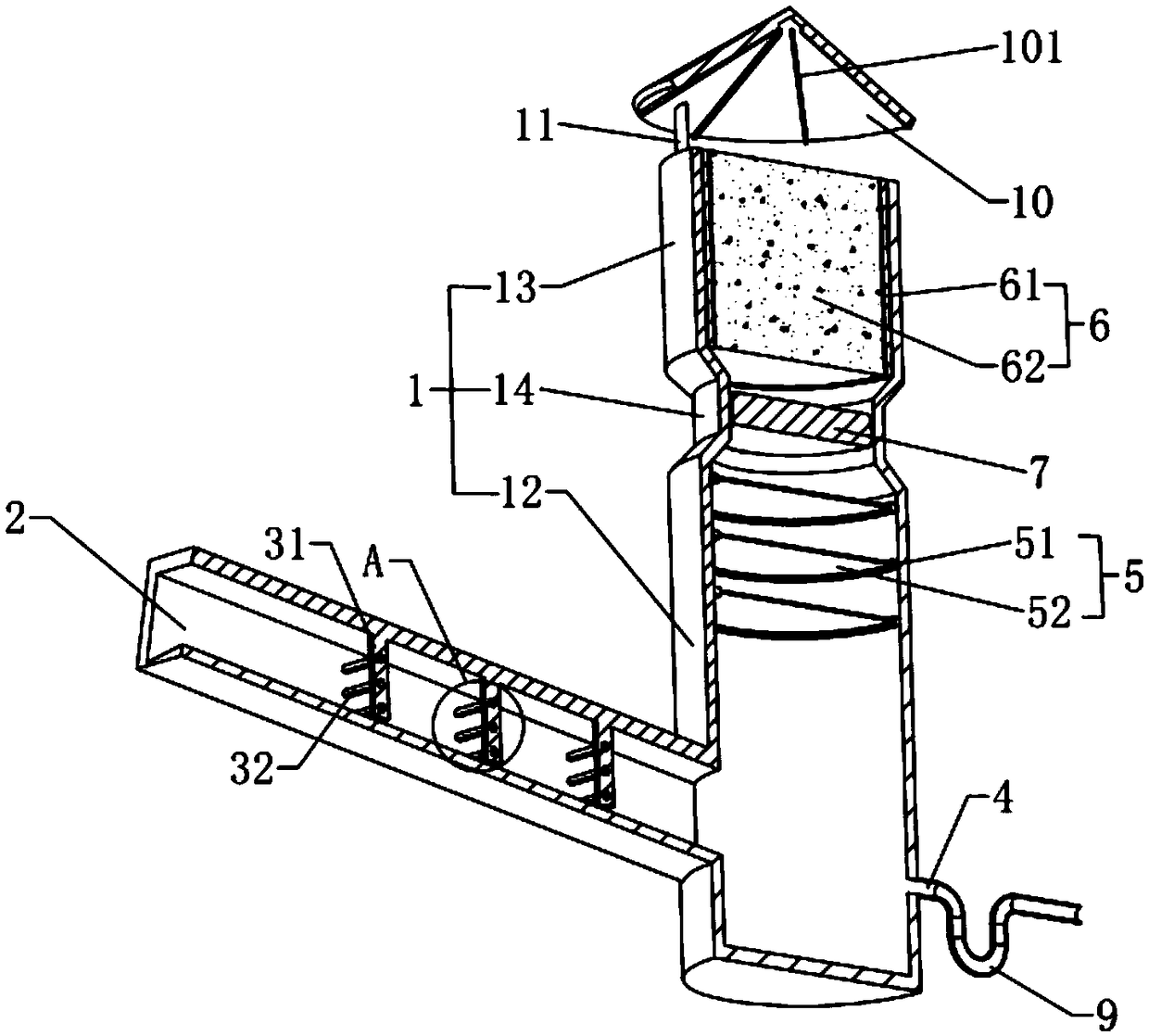

[0039] refer to figure 1 , an environment-friendly air purification device, used to treat the waste gas produced in the painting workshop, including a main tower 1, the main tower 1 is a hollow structure, the side of the main tower 1 is provided with an air inlet pipe 2, and the air inlet pipe 2 is connected to the main tower 1. The exhaust gas enters from the air inlet pipe 2 and is discharged from the top of the main tower 1.

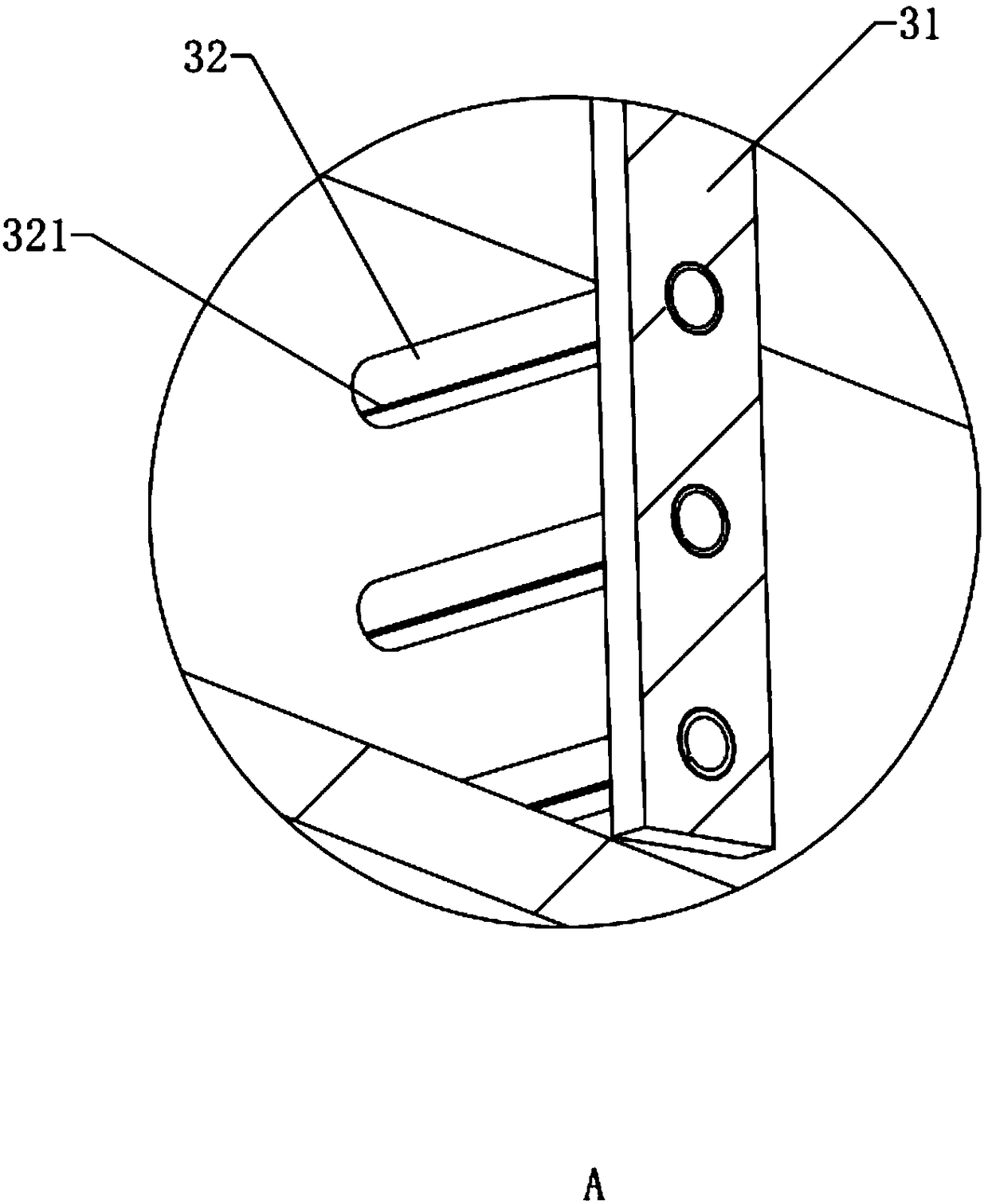

[0040] refer to figure 2 and image 3 , some water curtain devices 3 are arranged in the air inlet pipe 2, and the water curtain devices 3 are used to produce a water curtain. slit 321, the nozzle 32 is used to connect with the water pipe, and the water pipe passes water into the nozzle 32 and sprays out from the nozzle 321 to form a water curtain. When the exhaust gas passes through, the water curtain blocks and dissolves the large particles of impurities in the exhaust gas Remove water-soluble impurities and toxic gases such as ammonia nitrogen ...

Embodiment 2

[0052] The difference with embodiment 1 is the preparation of anti-adhesion coating, and its preparation method is as follows:

[0053] Take the following components by weight for later use: 32 parts of epoxy resin, 25 parts of polytetrafluoroethylene, 16 parts of polyvinyl chloride, 64 parts of acetone, 22 parts of ether, 6 parts of ethyl acetate, and 8 parts of polymethacrylate 5 parts, 5 parts of hydroxyalkyl methacrylate, 6 parts of ethyl methacrylate;

[0054] S1. Prepare the first prefabricated solution: add epoxy resin, polytetrafluoroethylene, and polyvinyl chloride into acetone to dissolve, stir evenly, heat the overall temperature to 58° C., and heat-preserve for 25 min to obtain the first prefabricated solution;

[0055] S2. Preparation of the second prefabricated solution: mix ethyl acetate, polymethacrylate, hydroxyalkyl methacrylate, ethyl methacrylate and diethyl ether evenly, heat the overall temperature to 44°C, heat preservation for 35min, Obtain the second ...

Embodiment 3

[0060] The difference with embodiment 1 is the preparation of anti-adhesion coating, and its preparation method is as follows:

[0061] Take the following components by weight for later use: 32 parts of epoxy resin, 25 parts of polytetrafluoroethylene, 16 parts of polyvinyl chloride, 70 parts of acetone, 24 parts of ether, 6 parts of ethyl acetate, 8 parts of polymethacrylate 5 parts, 5 parts of hydroxyalkyl methacrylate, 6 parts of ethyl methacrylate;

[0062] S1. Prepare the first prefabricated solution: add epoxy resin, polytetrafluoroethylene, and polyvinyl chloride into acetone to dissolve, stir evenly, heat the overall temperature to 58° C., and heat-preserve for 25 min to obtain the first prefabricated solution;

[0063] S2. Preparation of the second prefabricated solution: mix ethyl acetate, polymethacrylate, hydroxyalkyl methacrylate, ethyl methacrylate and diethyl ether evenly, heat the overall temperature to 44°C, heat preservation for 35min, Obtain the second pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com