A seedling raising device suitable for machine-transplanted older seedlings and its application

A seedling and older technology, which is applied in the field of agricultural cultivation, can solve the problems of increasing the difficulty of water management of seedlings, delaying the harvest time, aligning seedlings, and having a great impact on root packing, so as to reduce the risk of burning seedlings and dead seedlings, and improve the rate of full seedlings and strong seedlings , Increase the uniformity of seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

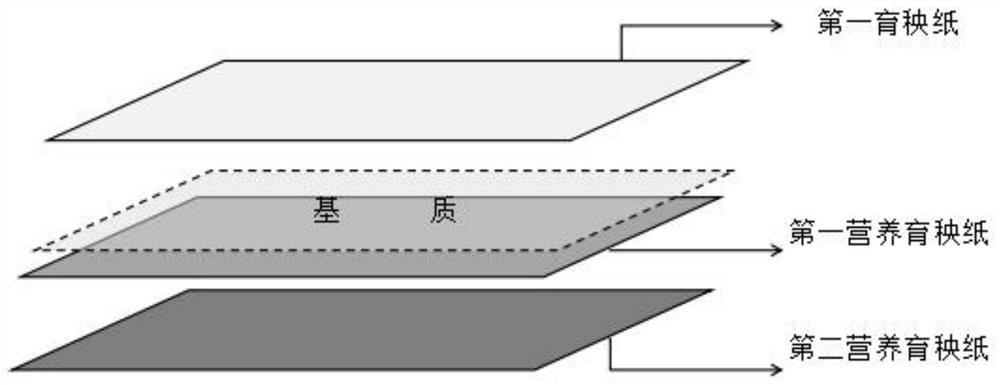

Image

Examples

preparation example Construction

[0029] The first nutritional seedling-raising paper and the second nutritional seedling-raising paper in the present invention are preferably seedling-raising papers from the same source, and the preparation methods of the first nutritional seedling-raising paper and the second nutritional seedling-raising paper include: using potassium sulfate solution to modify wheat straw Sexual treatment to obtain fiber gel; mix the fiber gel with water-absorbent resin, plastic absorber and cross-linking agent to obtain a mixed homogeneous slurry; the mixed homogeneous slurry is sequentially paved and formed, dried into paper and cut Winding, get nutritious seedling raising paper. In the present invention, when preparing the nutritional seedling-raising paper, potassium sulfate solution is used to modify wheat straw to obtain fiber gel. In the present invention, the wheat straw is preferably pretreated before use, and the pretreatment process is preferably cutting the wheat straw into 2-3 ...

Embodiment 1

[0040] The wheat straw was cut into 2 cm long segments with a guillotine, and then soaked in 4% potassium sulfate solution for 7 days; the soaked wheat straw was boiled in a pot for 30 minutes to obtain a fiber gel. Put the fiber gel into the beating tank, make the mass concentration of the fiber gel in the tank reach 65%, then add sodium polyacrylate, water-based polyurethane and polyvinyl alcohol respectively, and stir evenly; make the three in the homogenate The mass concentration of the mixture reached 2%, 3% and 1% in turn to obtain a mixed homogenate; the mixed homogenate was transported to the inclined wire former for molding treatment until the mixed homogenate was deposited into raw pulp wet paper, and then The raw pulp wet paper is dried at 100°C, so that the moisture content of the raw pulp wet paper is 15%, and the dried raw pulp paper is obtained; the dried raw pulp paper is cut into 280mm width with a guillotine The paper tape is then wound into nutrient seedling...

Embodiment 2

[0050] The wheat straw was cut into 2 cm long segments with a guillotine, and then soaked in 4% potassium sulfate solution for 7 days; the soaked wheat straw was boiled in a pot for 30 minutes to obtain a fiber gel. Put the fiber gel into the beating tank, make the mass concentration of the fiber gel in the tank reach 65%, then add sodium polyacrylate, water-based polyurethane and polyvinyl alcohol respectively, and stir evenly; make the three in the homogenate The mass concentration of the mixture reached 2%, 3% and 1% in turn to obtain a mixed homogenate; the mixed homogenate was transported to the inclined wire former for molding treatment until the mixed homogenate was deposited into raw pulp wet paper, and then The raw pulp wet paper is dried at 100°C, so that the moisture content of the raw pulp wet paper is 15%, and the dried raw pulp paper is obtained; the dried raw pulp paper is cut into 280mm width with a guillotine The paper tape is then wound into nutrient seedling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com