Hydrogen sensor for detecting dissolved gas in oil

A technology of dissolved gas and sensors in oil, which is applied in the field of hydrogen sensors, can solve the problems of service life limitation, delayed equipment fault identification and diagnosis, etc., and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings, but it should be noted that these embodiments are not limitations on this patent, and those of ordinary skill in the art based on the functions, methods, or structures made by these embodiments Equivalent transformation or substitution all fall within the scope of protection of this patent.

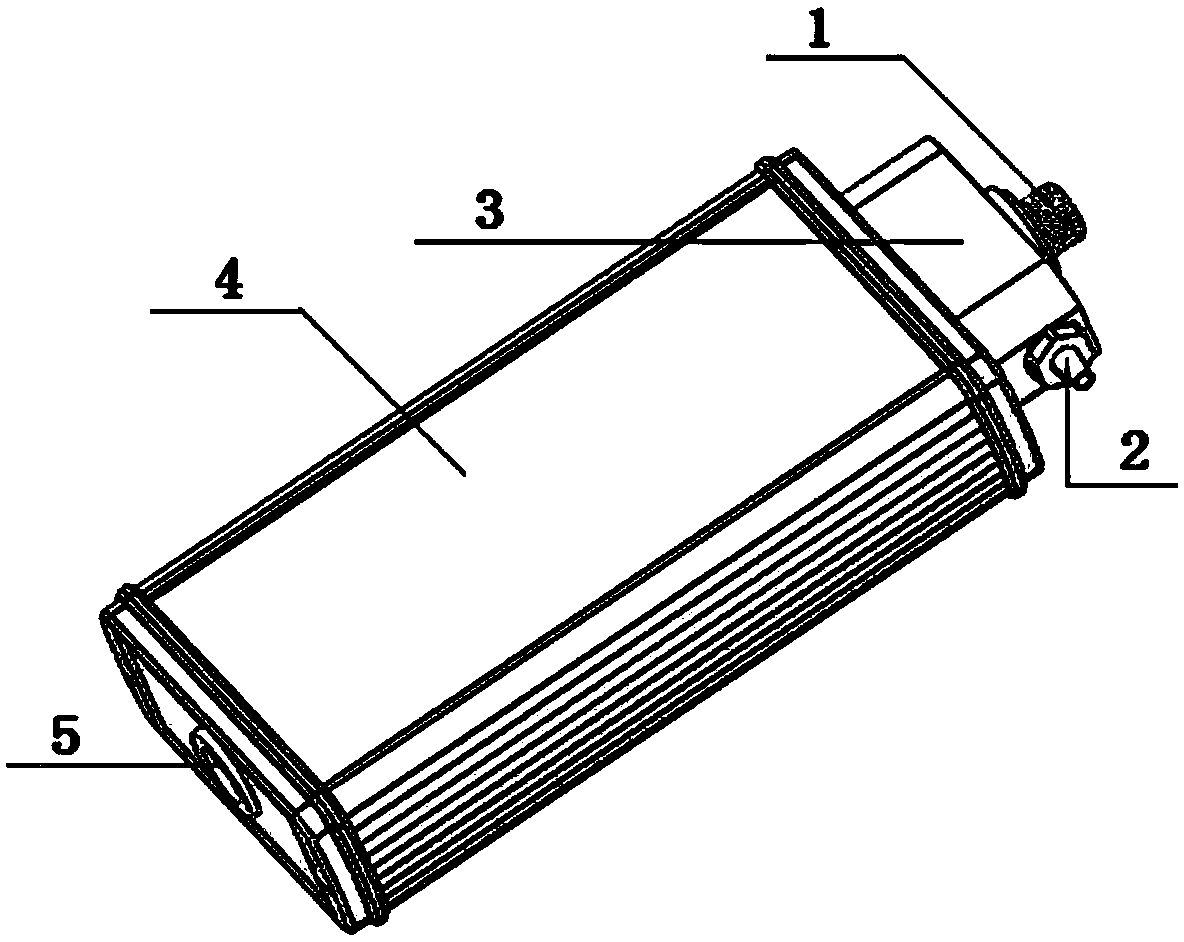

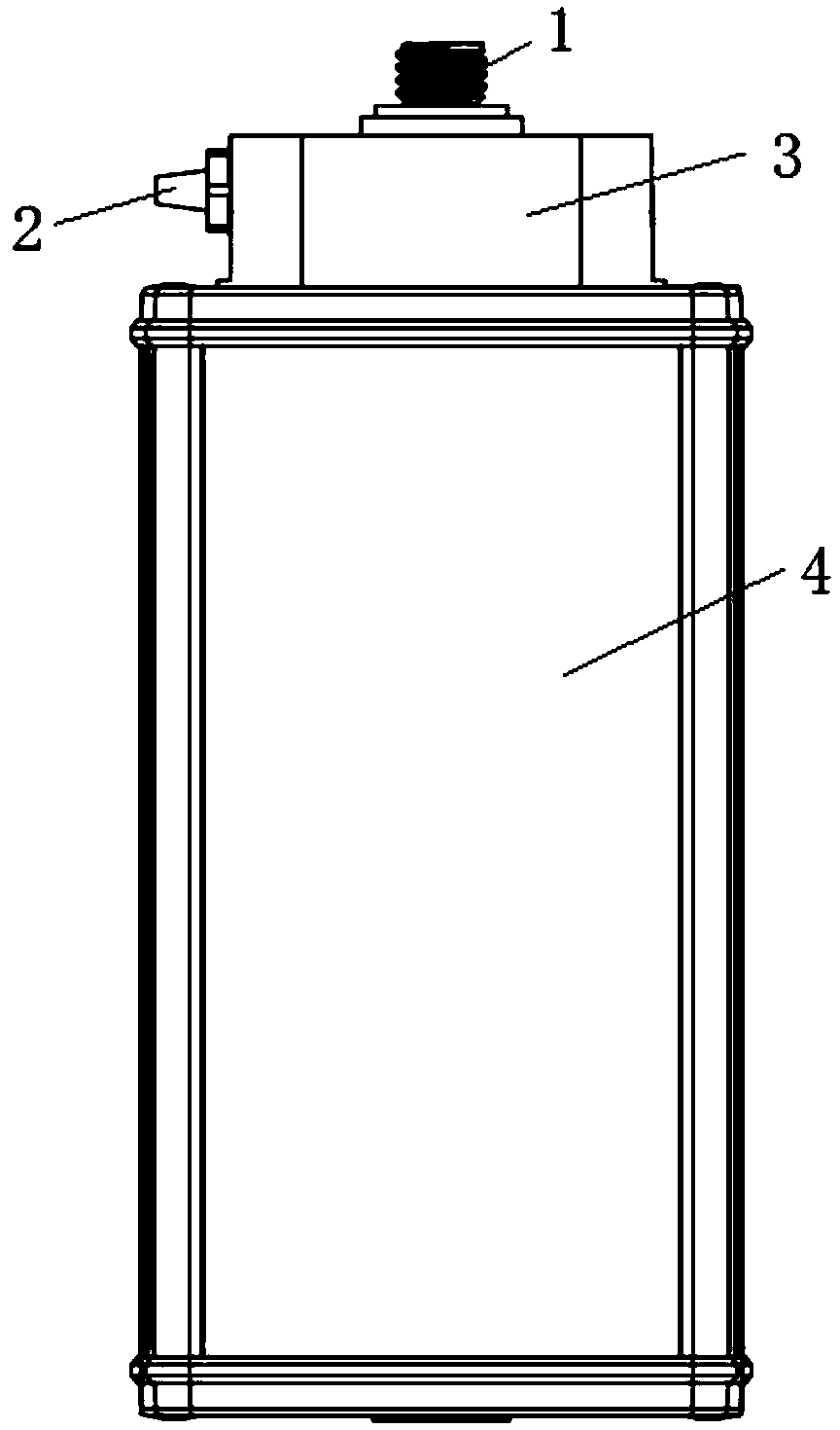

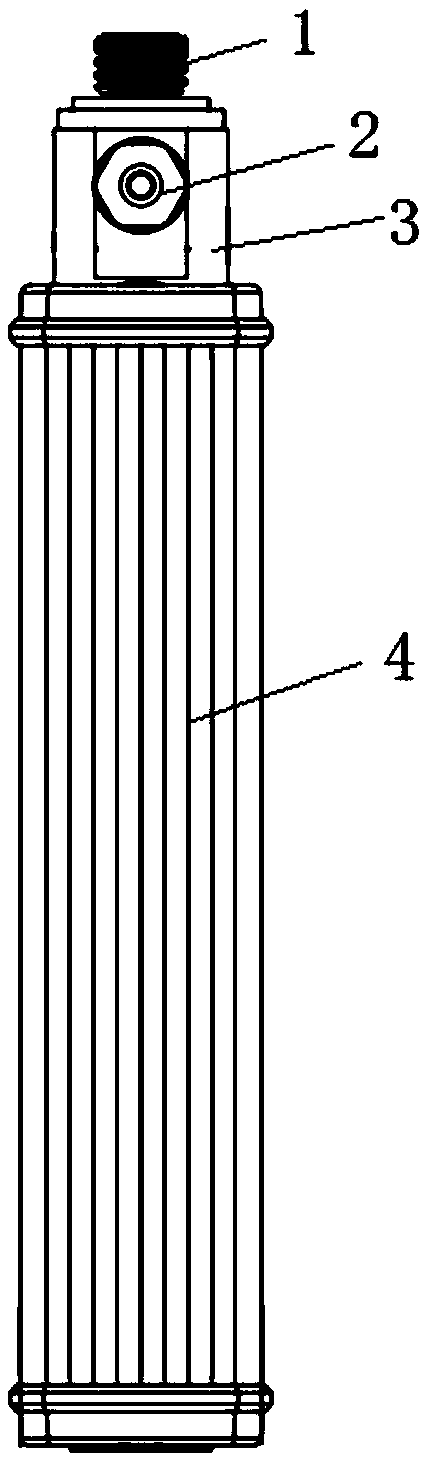

[0023] Such as Figure 1 to Figure 4 As shown, a hydrogen sensor for detecting dissolved gas in oil includes an adapter interface 1, an oil valve 2, a hydrogen sensor module 3 and a conversion circuit module 4, and the hydrogen sensor module 3 and the conversion circuit module 4 are plugged together file connection.

[0024] The hydrogen sensing module 3 includes a hydrogen sensitive chip and a temperature controller packaged in the first casing, the hydrogen sensitive chip is connected to the processor module of the conversion circuit module 4, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com