Neutron measurement method for studying microstructure of brittle material

A measurement method and microstructure technology, which is applied to the use of wave/particle radiation for material analysis, measurement devices, and analysis of materials. It can solve problems such as inability to carry out, cameras blocking neutron beams, etc., to reduce position errors and ensure consistency. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

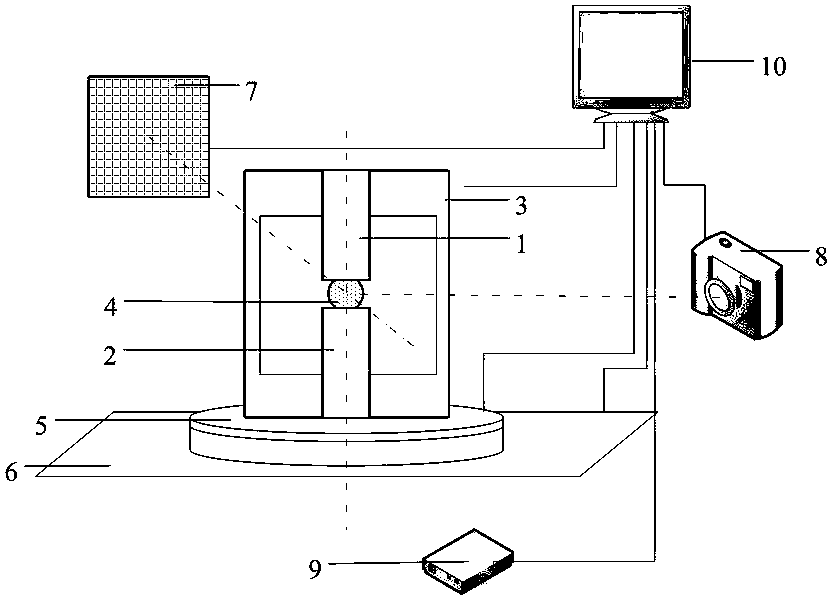

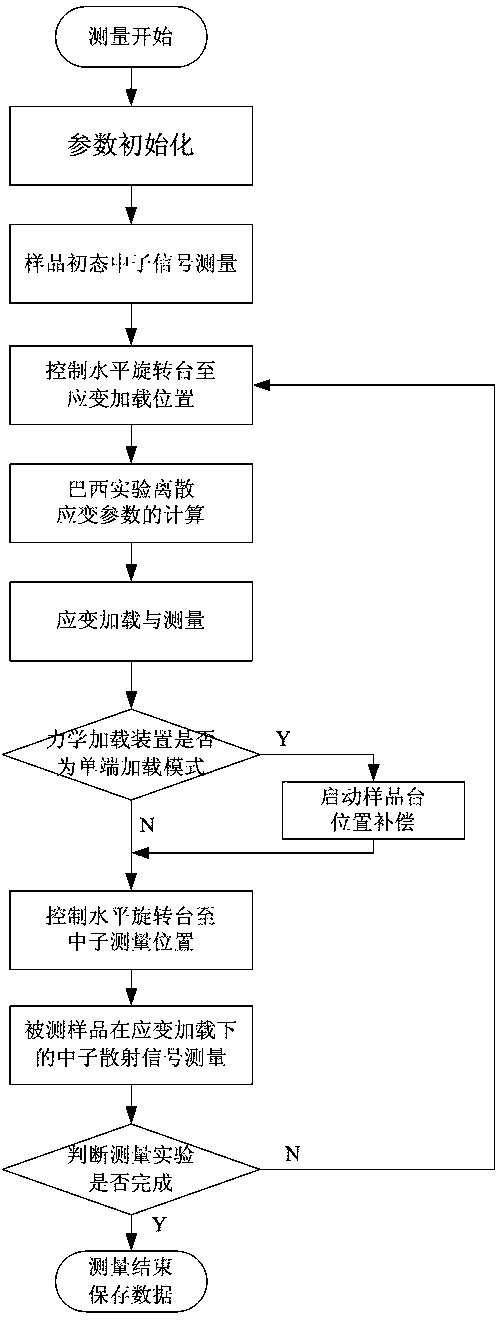

[0025] Such as figure 2 As shown, the mechanical loading device 3 of the neutron measurement method used for the microstructure research of brittle materials in this embodiment is the upper end fixed lower end loading mode, and the sample stage 6 has a lifting function. The measurement method includes the following steps:

[0026] a. Parameter initialization and sample initial state measurement: set the number of single-step neutron measurements measured by the neutron small-angle scattering spectrometer, and the sample diameter D s The sample information parameter and the sample thickness, initialize the current strain parameter T of the measured sample 4 c and control the current position A of the horizontal turntable 5 r be zero; start the neutron monitor 9 to count the measured neutrons, start the neutron detector 7 to measure the scattering signal of the tested sample 4, and obtain the measurement result of the initial state of the sample;

[0027] b. Control the hor...

Embodiment 2

[0036] The neutron measurement method used in the study of the microstructure of brittle materials in this embodiment is basically the same as that in Embodiment 1, except that the camera 8 of the speckle strain gauge in this embodiment is placed on the right side of the sample stage 6 , The mechanical loading device 3 is a loading mode with the lower end fixed and the upper end loaded.

[0037] Step b is: control the horizontal rotary table 5 to the strain loading position: control the horizontal rotary table 5 to rotate to the right at a fixed angle θ, so that the sample surface faces the lens of the camera 8 of the speckle strain gauge;

[0038] Step d is: strain loading and measurement: set T c The value of is assigned to the nearest dependent variable T c-last ; Control the mechanical loading device 3 to perform mechanical loading on the tested sample 4, and the loading displacement is L Δ , during the loading process, the speckle strain gauge measures and feeds back th...

Embodiment 3

[0040] The implementation of the neutron measurement method for studying the microstructure of brittle materials in this embodiment is basically the same as that in Embodiment 1, except that the mechanical loading device is a double-end simultaneous loading method.

[0041] Step d is: strain loading and measurement: set T c The value of is assigned to the nearest dependent variable T c-last ; Control the mechanical loading device 3 to perform mechanical loading on the tested sample 4, and the loading displacement is L Δ , during the loading process, the speckle strain gauge measures and feeds back the actual deformation L of the tested sample 4 r ; After the loading is complete, update the current strain T c parameter, the calculation formula is: T c = T c-last +L r / D s .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com