Manufacturing method of pressure sensor for scraper test platform of painted sheet metal parts

A technology of pressure sensor and test platform, which is applied in the measurement of the property and force of piezoelectric devices, etc., and can solve the problems of low work efficiency, cumbersome operation and troublesome operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

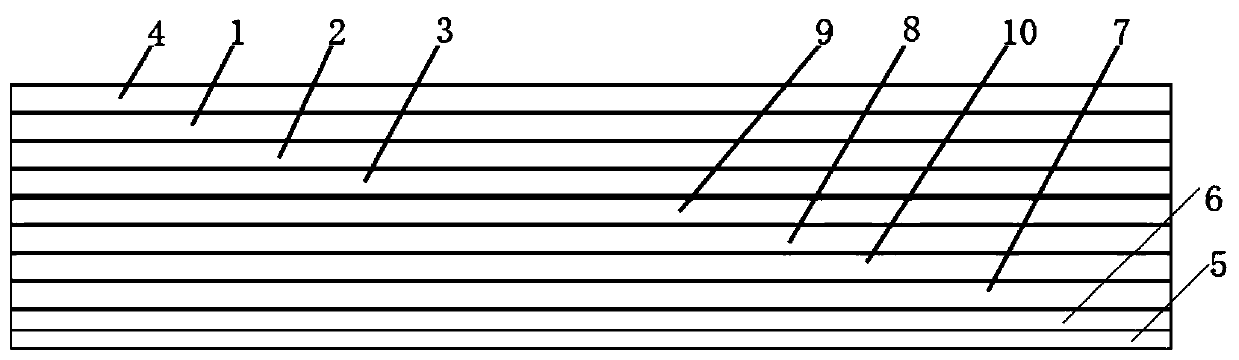

[0056] The schematic cross-sectional view of the pressure sensor used for the scraper test of painted sheet metal parts in this embodiment is shown in figure 1 , for the convenience of understanding, the figure does not follow the thickness ratio of each layer. The pressure sensor is a thin-film sensor; the thin-film sensor from top to bottom is PET substrate single-sided adhesive 4, upper line PET substrate layer 1, high-resistance carbon film layer 2, anisotropic conductive adhesive film layer 3, blue Upper protective film 9, PET substrate double-sided adhesive tape 8, blue lower protective film 10, insulating protective film layer 7, high conductivity silver film layer 6, lower line PET substrate layer 5. Upper line PET substrate layer 1, high resistance carbon film layer 2, anisotropic conductive adhesive film layer 3 constitute the upper circuit layer; insulating protective film layer 7, high conductivity silver film layer 6, and lower circuit PET substrate layer 5 The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com