Grain storage horizontal warehouse and pouring method for grain storage horizontal warehouse wall body

A one-story warehouse and wall technology, which is applied to walls, buildings, building components, etc., can solve the problems of poor thermal insulation performance and air tightness, inability to meet the needs of grain storage, interference and damage of thermal insulation layers, etc., so as to improve thermal insulation performance. , Eliminate the reduction of thermal insulation effect and enhance the effect of load-bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

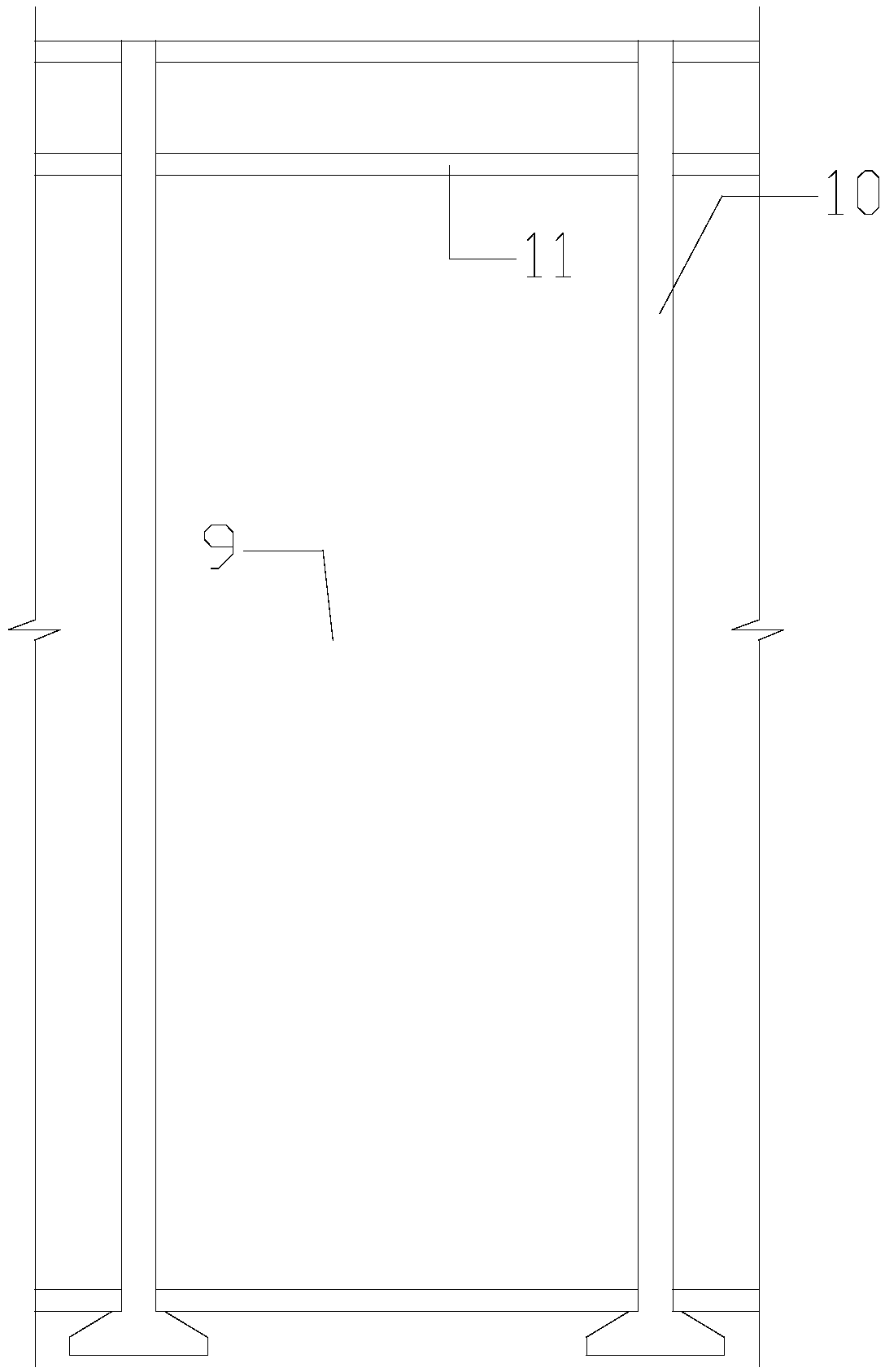

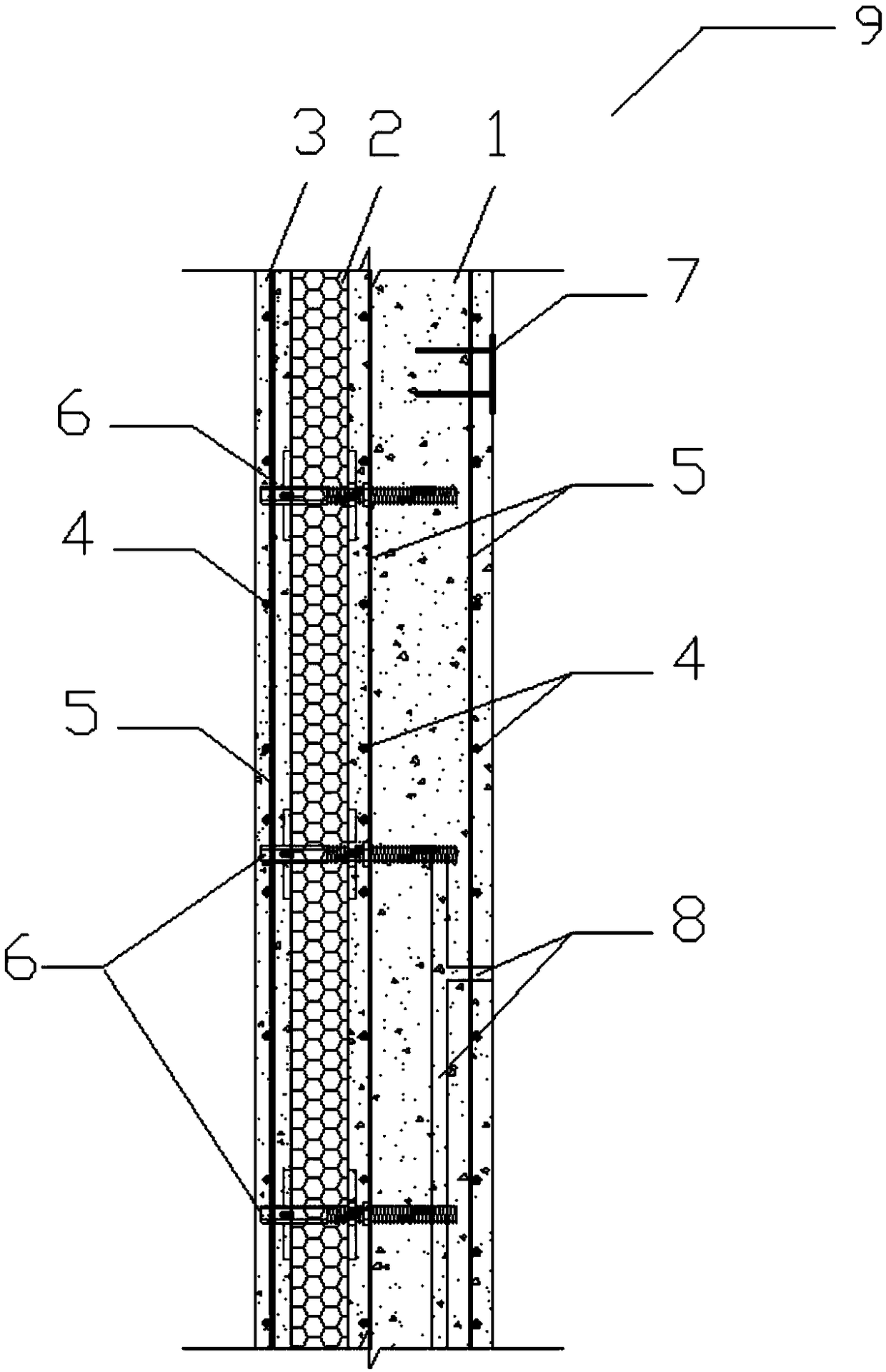

[0034] Example 1 - the wall of the grain storage bungalow

[0035]figure 1 A schematic diagram of the overall structure of the wall of the grain storage bungalow is shown. figure 2 It is a schematic cross-sectional view of the wall of the grain storage bungalow of the present invention. refer to figure 1 , there are a plurality of bent columns 10 ( figure 1 2 are shown in ), connecting beams 11 are provided between adjacent bent columns 10, thereby constituting the skeleton of the wall body 9 as a whole. refer to figure 2 , The wall body 9 of the flat grain storage warehouse of the present invention includes: an inner leaf wall 1 , an insulating layer 2 , an outer leaf wall 3 and a connector 6 . In general, the insulation layer 2 is located between the inner leaf wall 1 and the outer leaf wall 3, the connecting piece 6 is a rod structure with a certain length, the connecting piece 6 runs through the insulating layer 2, and one end of the connecting piece 6 is connected...

Embodiment 2

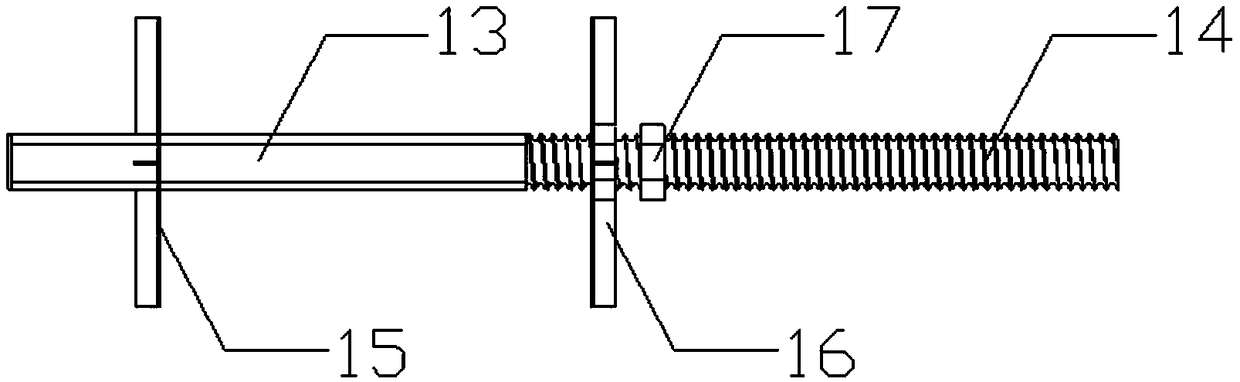

[0041] Example 2 - connector

[0042] image 3 The connecting piece 6 of the present invention is shown, and the connecting piece 6 includes: a rod, a fixed clip 15, a movable clip 16 and a positioning nut 17, wherein the rod includes a hollow round steel pipe 13 and a threaded steel 14, and the hollow round steel pipe 13 Connected with threaded steel 14, the two are welded together and can be regarded as an integral structure, and the size of the hollow round steel pipe 13 and the threaded steel 14 can also be adapted, so that one end of the threaded steel 14 can be accommodated inside the hollow round steel pipe 13, and the hollow The central axis of the circular steel pipe 13 coincides with the threaded steel 14. Further, the inner wall of the hollow round steel pipe 13 may have threads, which are adapted to the threads of the rebar 14, and the hollow round steel pipe 13 and the rebar 14 may form a threaded connection. When using, refer to figure 2 , the hollow round ...

Embodiment 3

[0050] Embodiment 3-Construction technology of grain storage one-story warehouse wall

[0051] The construction process of the wall of the grain storage bungalow of the present invention mainly adopts the cast-in-place method. First, the insulation layer 2 located in the middle layer, such as an extruded polystyrene insulation board, is fixed in place, and then the hollow circle of the connector 6 is fixed in place. The steel pipe 13 and the threaded steel 14 are inserted into the extruded polystyrene insulation board. One end of the connecting piece 6 is positioned due to the existence of the fixed clip 15, and the other end of the connecting piece 6 is positioned using the movable clip 16 and the positioning nut 17. The specific method is: screw the movable clip 16 into the threaded steel 14 and tighten it, so that the fixed clip 15 and the movable clip 16 clamp the extruded polystyrene insulation board, then screw in the positioning nut 17 and tighten it so that it is clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com