Metal product surface corrosion resistance processing process

A treatment process and corrosion-resistant technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of oxidation and blackening of sandblasting surface, and achieve the effect of improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A metal product surface corrosion-resistant treatment process, comprising the following steps:

[0033] 1) Put metal products in a heat treatment furnace, and carry out surface nickel infiltration in a high-pressure argon environment and keep it warm for 2 hours and then cool down to 30-50°C; the preparation method of surface nickel infiltration is to process the processed After the metal product is sealed, it is buried in the mixture of nano-nickel powder and nano-carbon powder, heated to 350°C under 3MPa argon atmosphere, and kept for 2 hours, then cooled to 30-50°C. The mass ratio of nano-nickel powder to nano-carbon powder is 1:20.

[0034] 2) Put the metal product treated in step 1) in 12% ethylenediaminetetraacetic acid disodium aqueous solution for 5 seconds, take it out and dry it directly.

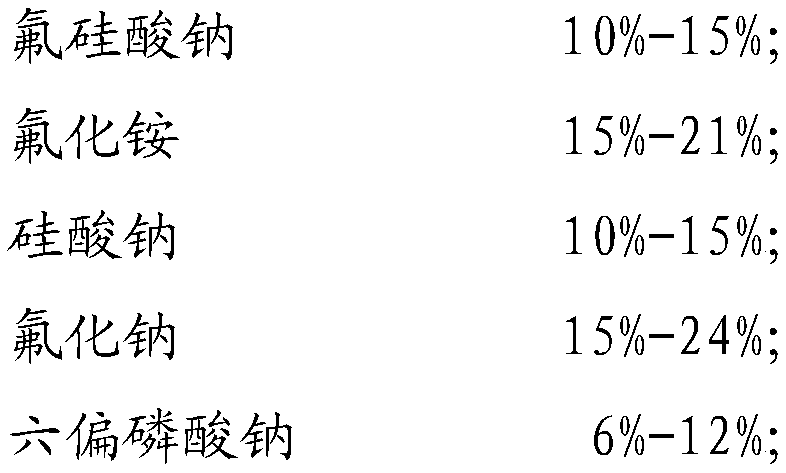

[0035] 3) Sandblasting the metal product after drying in step 2); the sandblasting treatment is ceramic sandblasting, and the surface roughness of the metal product is con...

Embodiment 2

[0039] A metal product surface corrosion-resistant treatment process, comprising the following steps:

[0040] 1) Put the metal product in a heat treatment furnace, and carry out surface nickel infiltration under high-pressure argon atmosphere and keep it warm for 4 hours and then cool down to 30-50°C; the preparation method of surface nickel infiltration is to process the processed After the metal product is sealed, it is buried in the mixture of nano-nickel powder and nano-carbon powder, heated to 380°C in an argon atmosphere of 5MPa, kept for 4 hours, and then cooled to 30-50°C. The mass ratio of nano nickel powder to nano carbon powder is 1:10.

[0041] 2) Put the metal product treated in step 1) in 12% disodium edetate aqueous solution for 10 seconds, take it out and dry it directly.

[0042] 3) Sandblasting the metal product after drying in step 2); the sandblasting treatment is ceramic sandblasting, and the surface roughness of the metal product is controlled at 40-60 ...

Embodiment 3

[0046] A metal product surface corrosion-resistant treatment process, comprising the following steps:

[0047] 1) Put metal products in a heat treatment furnace, and carry out surface nickel infiltration in a high-pressure argon environment and keep it warm for 3 hours and then cool down to 30-50°C; the preparation method of surface nickel infiltration is to process the processed After the metal product is sealed, it is buried in a mixture of nano-nickel powder and nano-carbon powder, heated to 360°C in a 4MPa argon atmosphere, kept for 3 hours, and then cooled to 30-50°C. The mass ratio of nano-nickel powder to nano-carbon powder is 1:15.

[0048] 2) Put the metal product treated in step 1) in 12% ethylenediaminetetraacetic acid disodium aqueous solution for 5 seconds, take it out and dry it directly.

[0049] 3) Sandblasting the metal product after drying in step 2); the sandblasting treatment is ceramic sandblasting, and the surface roughness of the metal product is contro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com