Surface coating used for low reflective index color steel plate

A surface coating and reflectivity technology, applied in anti-corrosion coatings, fire-resistant coatings, radiation-absorbing coatings, etc., can solve the problems of insufficiency of salt corrosion, poor surface performance, etc., and achieve low pollution hazards, good compatibility, electromagnetic Good shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment relates to a surface coating for a color steel plate with low reflectance and a preparation method thereof. The coating consists of the following raw materials in parts by weight:

[0054] 47 parts of acrylic resin;

[0055] 22 parts of furan resin;

[0056] 4 parts red stone fat;

[0057] 6 parts of periclase powder;

[0058] 8 parts of isopropanol;

[0059] 3.5 parts of snail mucus;

[0060] 1 part of cellulose acetate butyrate;

[0061] 2.5 parts of ultrafine hexagonal boron nitride nanoparticles;

[0062] Accelerator 0.6 parts;

[0063] 0.9 parts of crosslinking agent;

[0064] 0.5 parts of coupling agent;

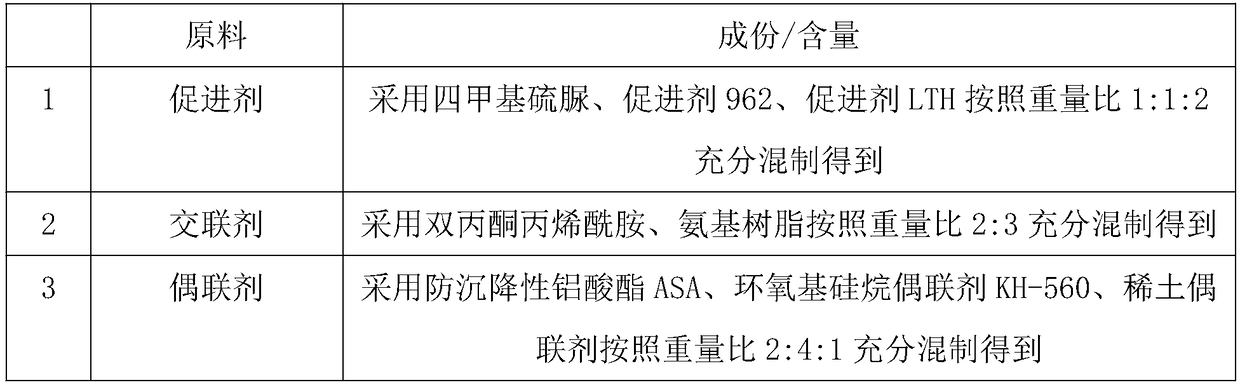

[0065] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 1 below:

[0066] Table 1

[0067]

[0068] The preparation method of present embodiment coating is carried out according to the following steps:

Embodiment 2

[0074] This embodiment relates to a surface coating for a color steel plate with low reflectance and a preparation method thereof. The coating consists of the following raw materials in parts by weight:

[0075] 49 parts of acrylic resin;

[0076] 24 parts of furan resin;

[0077] 4.5 parts of red stone fat;

[0078] 6.5 parts of periclase powder;

[0079] 9 parts of isopropanol;

[0080] 4 parts snail slime;

[0081] 1.2 parts of cellulose acetate butyrate;

[0082] 2.8 parts of ultrafine hexagonal boron nitride nanoparticles;

[0083] Accelerator 0.65 parts;

[0084] 0.95 parts of crosslinking agent;

[0085] 0.55 parts of coupling agent;

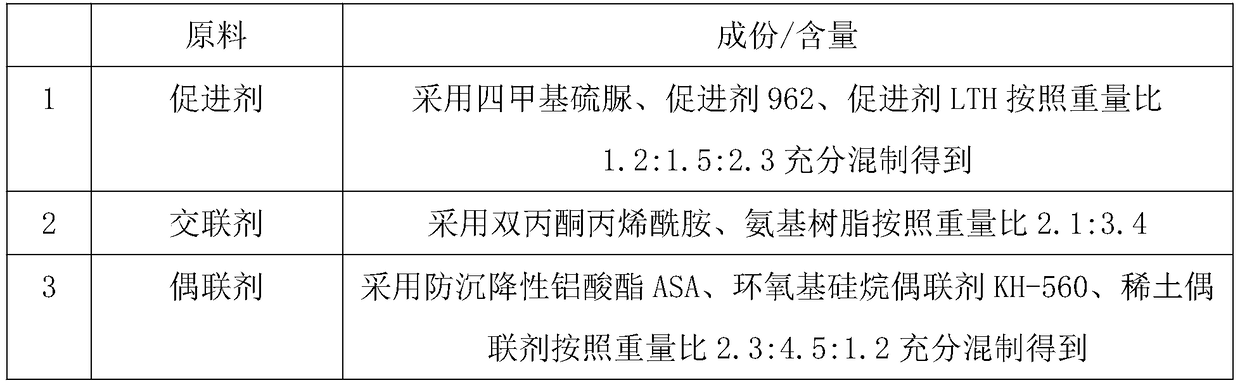

[0086] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 2 below:

[0087] Table 2

[0088]

[0089] The preparation method of present embodiment coating is carried out according to the following steps:

[0090] Ⅰ: Take red stone fat and periclas...

Embodiment 3

[0095] This embodiment relates to a surface coating for a color steel plate with low reflectance and a preparation method thereof. The coating consists of the following raw materials in parts by weight:

[0096] Acrylic resin 51 parts;

[0097] 25 parts of furan resin;

[0098] 5 parts red stone fat;

[0099] 7 parts of periclase powder;

[0100] 10 parts of isopropanol;

[0101] 4.5 parts of snail mucus;

[0102] 1.4 parts of cellulose acetate butyrate;

[0103] 3.2 parts of ultrafine hexagonal boron nitride nanoparticles;

[0104] Accelerator 0.7 part;

[0105] 1.0 parts of crosslinking agent;

[0106] 0.6 parts of coupling agent;

[0107] 1 part anti-cracking agent;

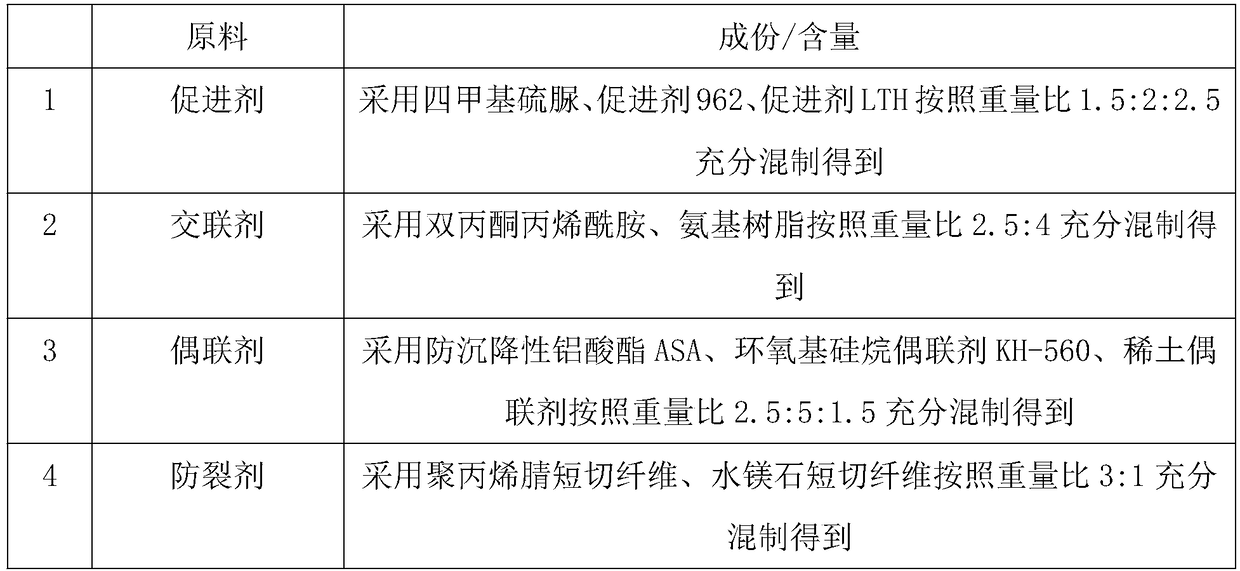

[0108] The selection and preparation of accelerator, cross-linking agent, coupling agent and anti-cracking agent in the present embodiment are shown in Table 3 below:

[0109] table 3

[0110]

[0111] The preparation method of present embodiment coating is carried out according to the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com