Refining method of cefathiamidine

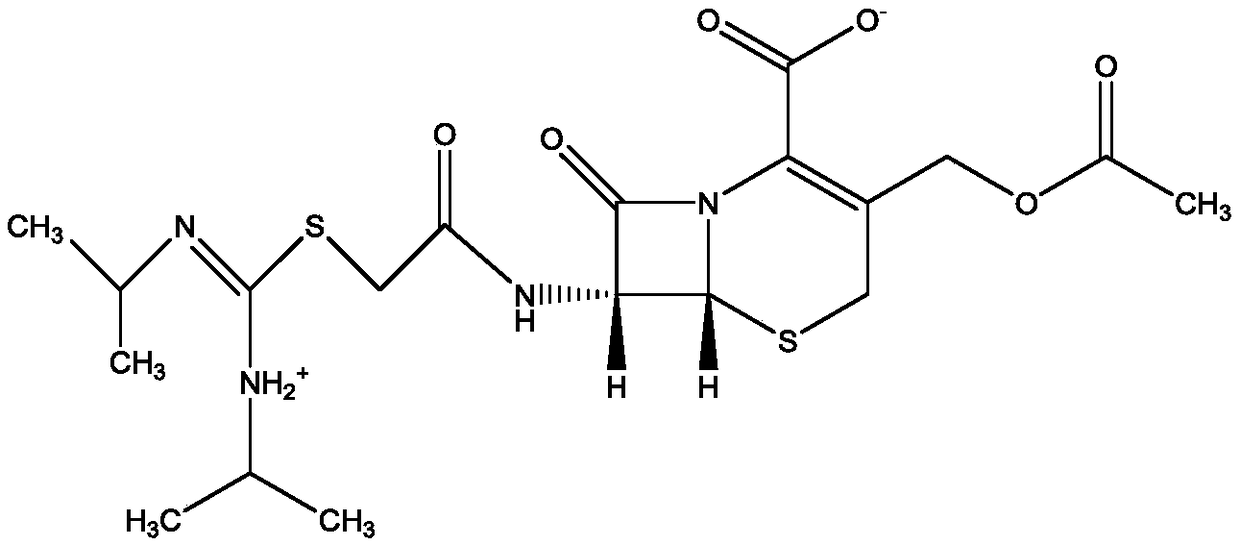

A cefathiamidine and purification method technology, applied in the field of chemical pharmacy, can solve the problems of affecting the yield of cefathiamidine crystals, low purity of cefathiamidine crystals, unable to meet the requirements for use, etc., to improve the effect of dissolution, filtration and decolorization, and the preparation method. Simple and easy to control, the effect of high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

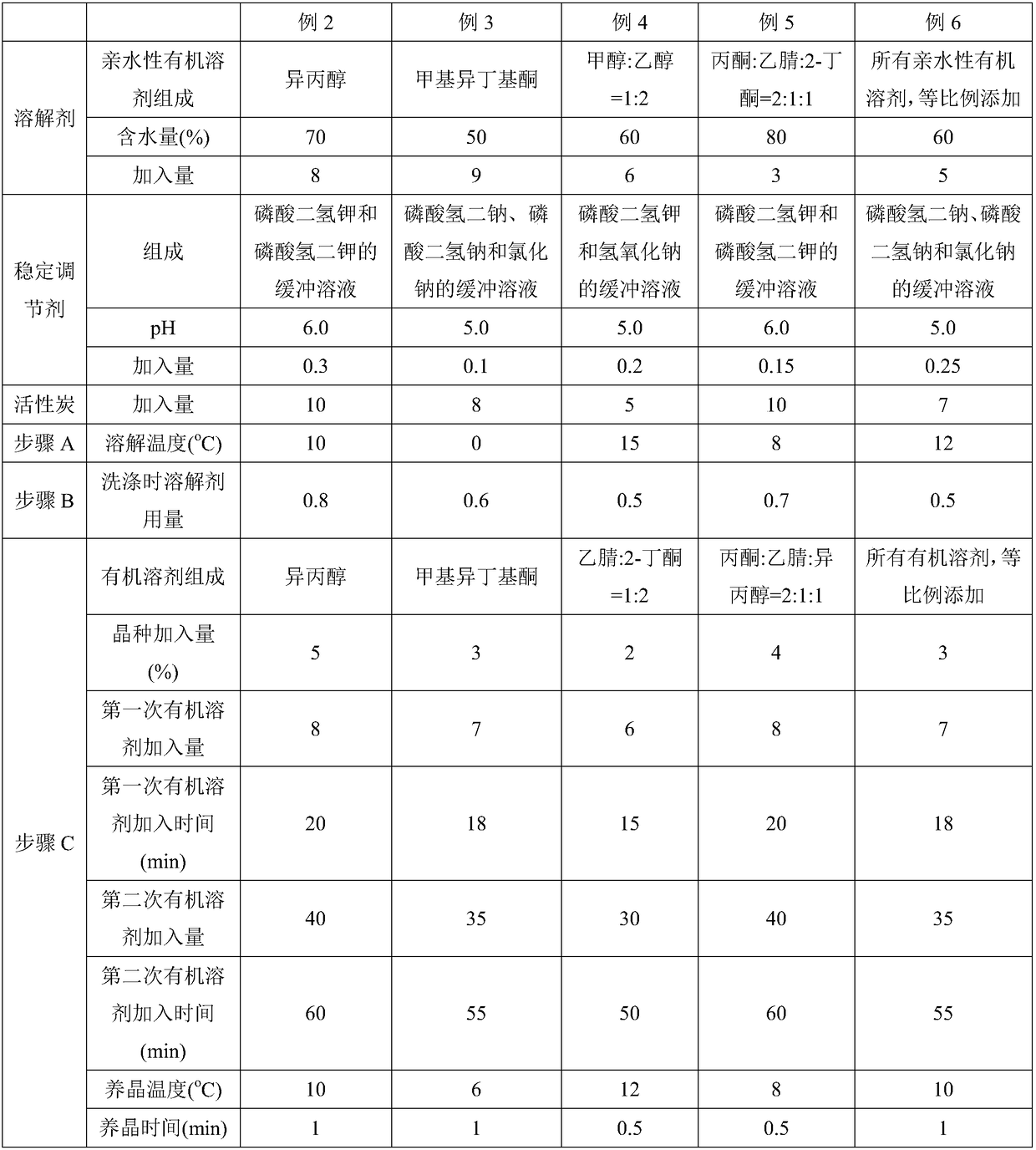

[0034] The preparation method comprises the following steps:

[0035]A. Add 3 to 9 times the dissolving agent of the cefathiamidine crude product quality in the reaction tank, then slowly add the cefathiamidine crude product, stir and dissolve at 0 to 15° C. to dissolve, and obtain the cefathiamidine crude product solution; the dissolving agent is Hydrophilic organic solvent containing water, the content of water in the dissolving agent is 40-80%; the hydrophilic organic solvent is acetone, methyl isobutyl ketone, isopropanol, methanol, ethanol, acetonitrile or 2-butanone any one or a combination of several;

[0036] B. Add 0.05 to 0.3 times of the cefathiamidine crude product quality stabilizer to the cefathiamidine crude product solution, stir evenly, then add 5 to 10% activated carbon of the cefathiamidine crude product quality, filter after stirring, and pass the filtrate into γ-type acidic alumina adsorption column, adjust the flow rate, collect the effluent, then wash t...

Embodiment 1

[0042] A method for refining cefathiamidine comprises the steps of dissolving crude cefathiamidine with a dissolving agent, adding a stabilizing regulator, and performing secondary decolorization by using an alumina adsorption column.

[0043] The preparation method comprises the following steps:

[0044] A. Add 40 mL of acetone containing 40% water in the reaction tank, and the dissolution temperature is 5° C., slowly add 10 g of cefathiamidine crude product, stir until dissolved, and obtain cefathiamidine crude product solution;

[0045] B. Add 0.5 mL of potassium dihydrogen phosphate and sodium hydroxide buffer solution with pH 5.0 to the crude cefathiamidine solution, stir evenly, then add 0.5 g of activated carbon, stir for 1 hour, filter, and pass the filtrate into γ-type acidic alumina For the adsorption column, adjust the flow rate to 2 mL / min, collect the effluent, then wash the alumina adsorption column with a dissolving agent, then wash with 4 mL of acetone containi...

Embodiment 7

[0053] This example is a comparative example. Prepare cefathiamidine according to the method described in the patent document CN102532165A. At -2°C, dissolve 20 g of cefathiamidine crude product in 180 mL of anhydrous methanol and 150 mL of anhydrous isopropanol, add 20 g of molecular sieves and 2 g of activated carbon after dissolution, and stir for dehydration , decolorize for 20min, filter, stir 60r / min, add 600mL of anhydrous isopropanol to the filtrate, add 4.5h, filter, wash twice with 80mL of anhydrous isopropanol, wash three times with 120mL of anhydrous acetone, 35 Cefathiamidine was dried under vacuum for 28 hours to obtain 15.13 g of cefathiamidine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com