Enzyme membrane reactor and method of using enzyme membrane reactor to treat wastewater

An enzyme membrane reactor and waste water technology, applied in chemical instruments and methods, biological treatment devices, biological water/sewage treatment, etc., to achieve the effects of high reactivity, long service life and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of immobilized enzyme membrane:

[0033] First prepare 0.25g / L sodium alginate aqueous solution, 2000u / ml horseradish peroxidase phosphate buffer, and the phosphate concentration is 10mM. Take 1.5mL of the prepared sodium alginate solution and horseradish peroxidase solution and mix evenly, and then coat the mixed solution on both sides of the nylon diaphragm (the diameter of the diaphragm is Φ100mm, and the aperture is 0.22μm), and let it stand 10min, then put into 0.1mol / L calcium chloride solution and let stand for 20min. Finally, stand in deionized water for 2.5 h before use.

[0034] 2) Enzyme membrane reactor to treat low-concentration phenol wastewater:

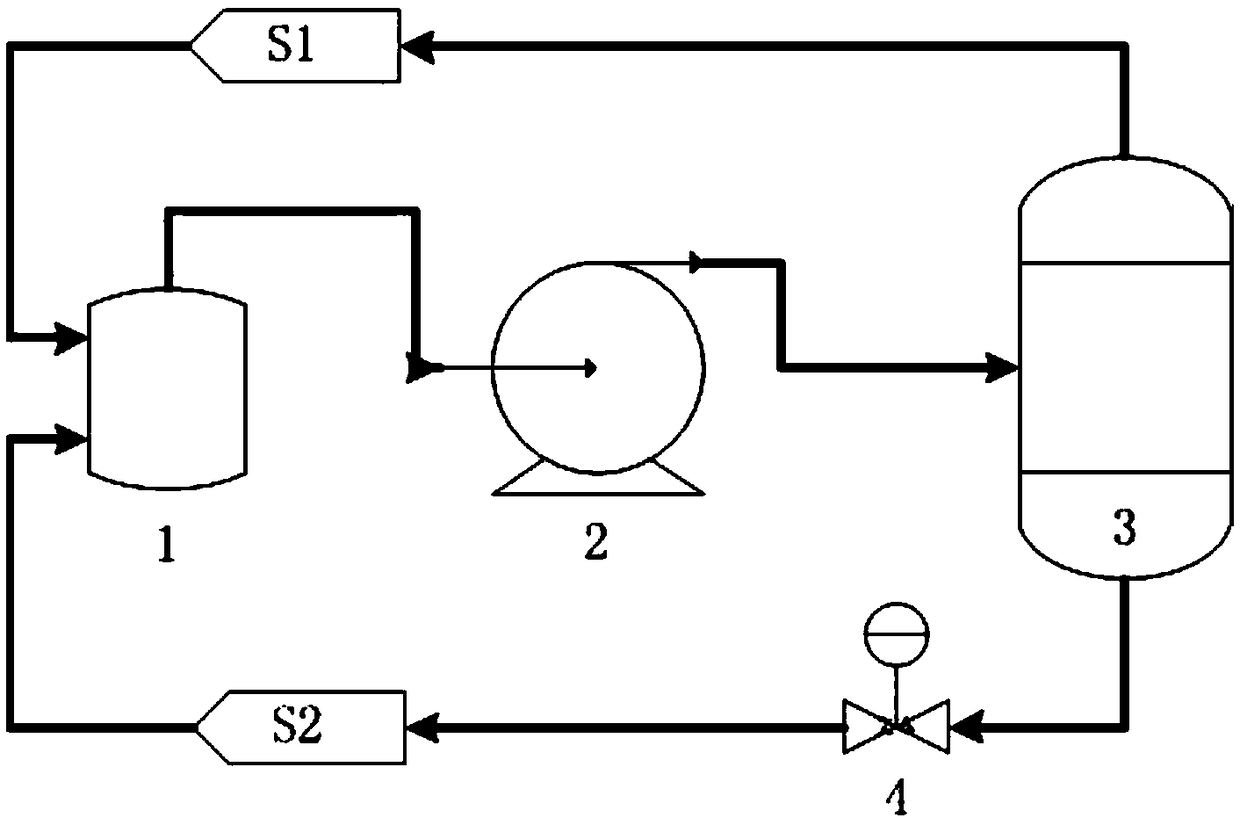

[0035] Treatment equipment composed of enzyme membrane reactors such as figure 1 , including an enzyme membrane reactor 3, a peristaltic pump 2, a beaker 1 containing 100mL of waste water, a water inlet pipe, a return water pipeline S1, and a final water outlet pipeline S2; the beaker 1 is conn...

Embodiment 2

[0040] 1) Preparation of immobilized enzyme membrane:

[0041] First prepare 0.5g / L sodium alginate aqueous solution, 3000u / ml horseradish peroxidase phosphate buffer, and the phosphate concentration is 10mM. Mix 1.5ml each of the prepared sodium alginate solution and horseradish peroxidase solution evenly, and then coat the mixed solution on a nylon diaphragm (Φ100mm, pore size 0.22μm), let it stand for 10min, and then put it in the Stand in 0.1mol / l calcium chloride solution for 20min. Finally, stand in deionized water for 2.5 h before use.

[0042] 2) Enzyme membrane reactor degrades bisphenol A, including:

[0043] The equipment structure for treating wastewater is the same as in Example 1, and the enzyme membrane reactor is made in step 1) of this example.

[0044] The immobilized enzyme membrane is placed in the reactor, and the peristaltic pump is started to flow the bisphenol A through the reactor, so that the bisphenol A fully reacts with the enzyme. The bisphenol...

Embodiment 3

[0047] 1) Preparation of immobilized enzyme membrane:

[0048]First prepare 0.125g / L sodium alginate aqueous solution, 1000u / ml horseradish peroxidase phosphate buffer, and the phosphate concentration is 10mM. Take 1.5ml of the prepared sodium alginate solution and horseradish peroxidase solution and mix evenly, then coat the mixed solution on a nylon diaphragm (Φ100mm, pore size 0.22μm), let it stand for 10min, and then put it in the Stand in 0.1mol / l calcium chloride solution for 20min. Finally, stand in deionized water for 2.5 h before use.

[0049] 2) Enzyme membrane reactor degrades rhodamine B, including:

[0050] The equipment structure for treating wastewater is the same as in Example 1, and the enzyme membrane reactor is made in step 1) of this example.

[0051] The immobilized enzyme membrane is placed in the reactor, and the peristaltic pump is started to flow the rhodamine B through the reactor, so that the rhodamine B fully reacts with the enzyme. The rhodamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com