Lithium battery code spraying and loading device

A lithium battery, coding technology, applied in transportation, packaging, conveyors, etc., can solve the problems of reduced coding accuracy and quality, easy adhesion of dust on the coding surface, unclear coding, etc., to improve accuracy and quality, Simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

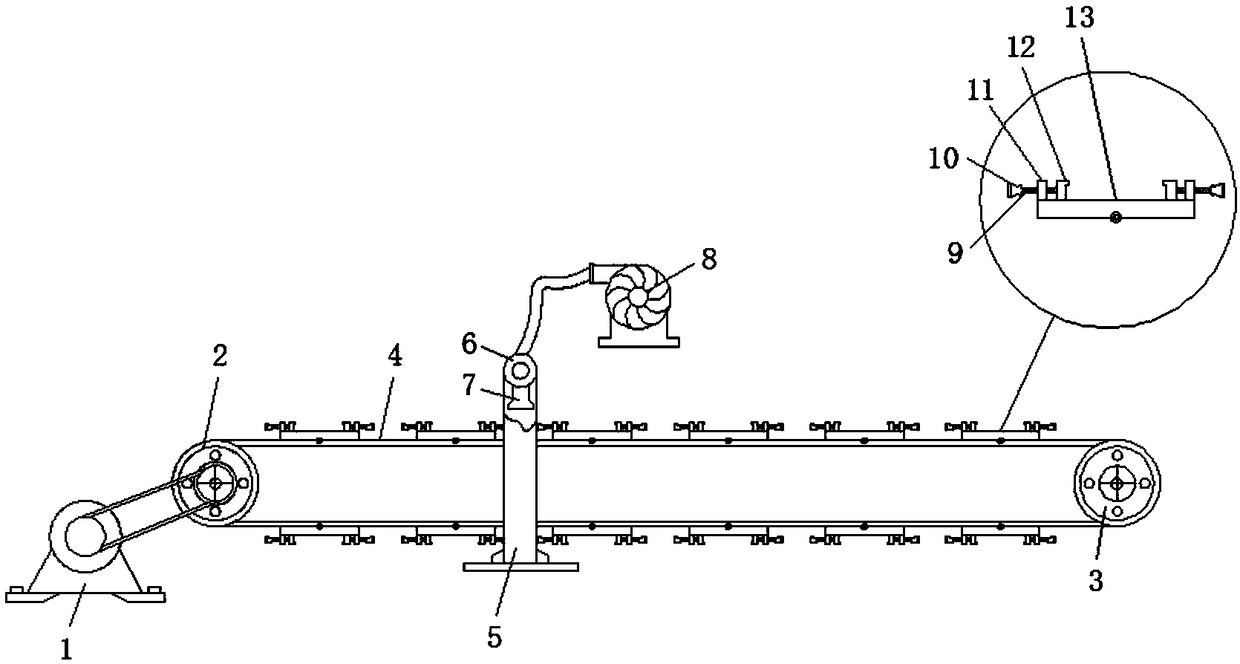

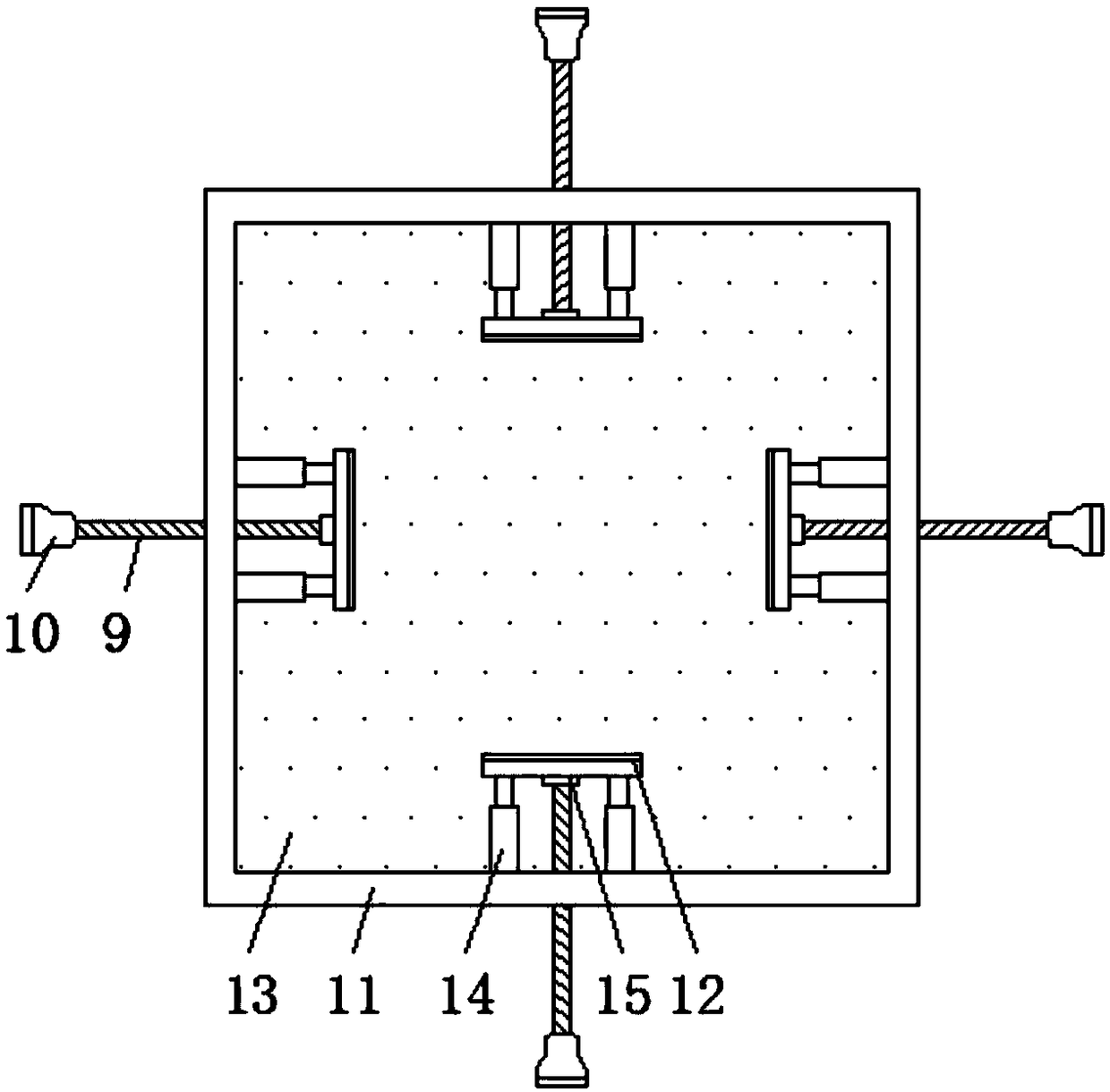

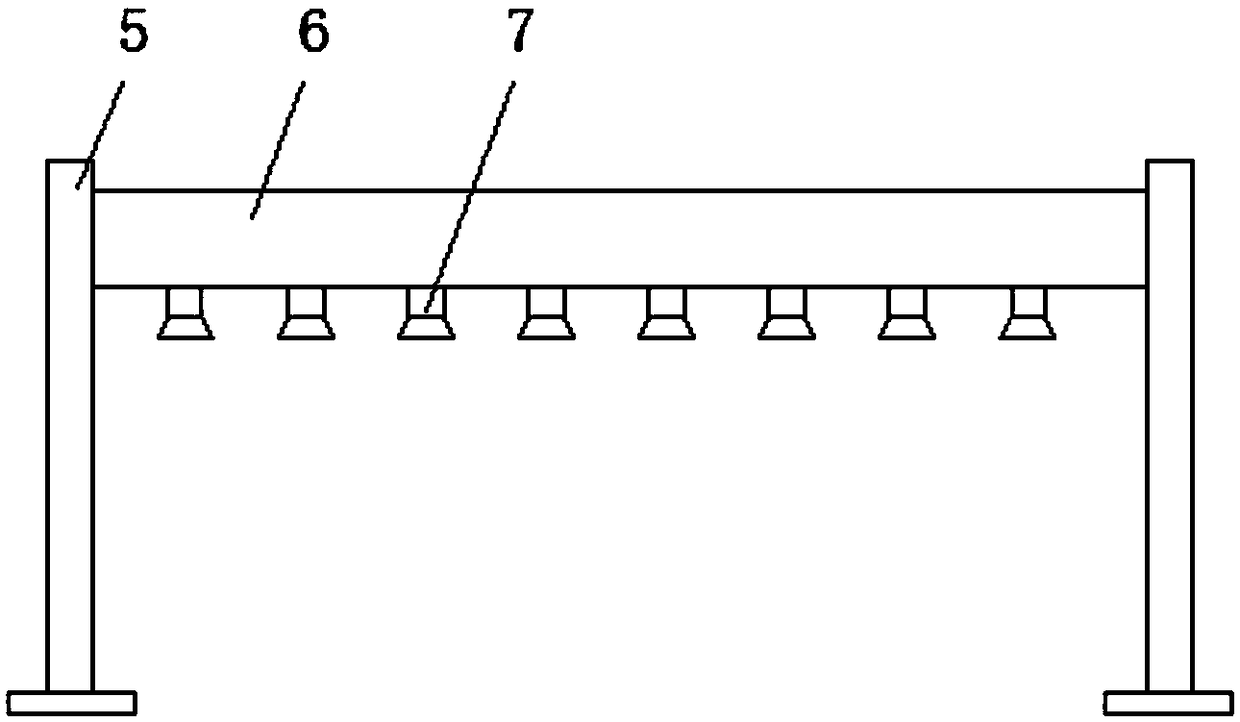

[0024] refer to Figure 1-3 , a lithium battery inkjet code feeding device, including a driving wheel 2, a driven wheel 3 and a conveyor belt 4, and the driving wheel 2 and the driven wheel 3 are connected through a transmission belt 4, and it is characterized in that the outer wall of the conveyor belt 4, etc. A plurality of fixed plates 13 are arranged at a distance, and the top edges of the plurality of fixed plates 13 are all welded with limit frame bars 11, and the insides of the four sides of the limit frame bars 11 are all provided with clamping plates 12 in parallel. One side of the position frame bar 11 is movably connected with a screw rod 9 through a fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com