Nozzle device

A nozzle device and nozzle technology, applied in the component field of casting equipment, can solve problems such as affecting operation, adhesion, casting failure, etc., and achieve the effect of changing the ability of spraying molten metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

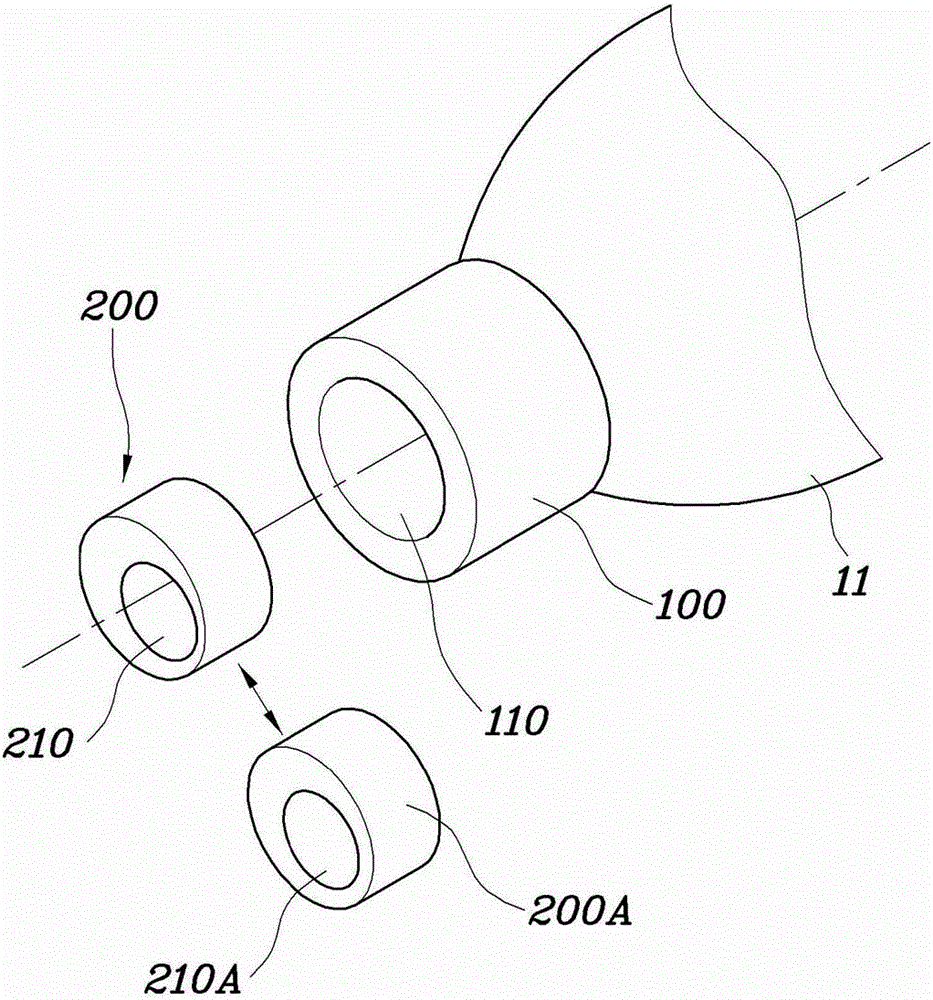

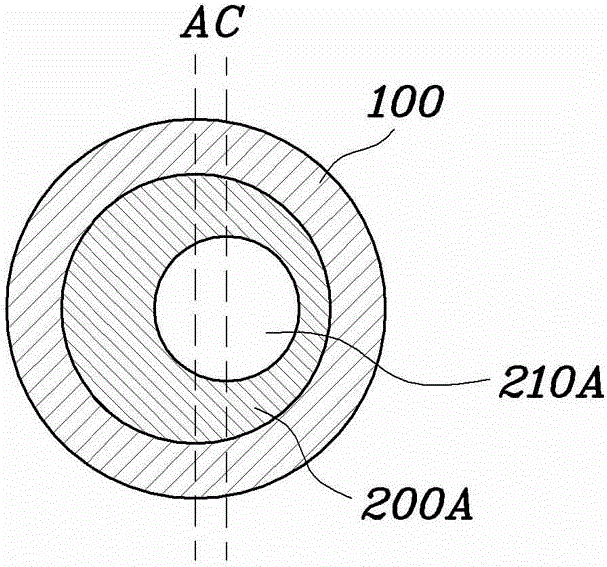

[0023] figure 1 , figure 2 and Figure 4 The reference signs include: nozzle device 11, molding die 4, injection port 15, molten metal 13, nozzle port inner wall 110, nozzle port 100, nozzle body 11, first nozzle body 220, first eccentric through hole 210, second Nozzle body 200A, second eccentric through hole 210A.

[0024] Such as figure 1 As shown, the nozzle device includes a nozzle body. The front end of the nozzle body 11 is provided with a nozzle opening 100;

[0025] A first nozzle body 220 and a second nozzle body 200A are installed in the nozzle opening, and the cross-sections of the outer walls of the two nozzle bodies are circular in shape matching the shape of the inner wall of the nozzle opening. The two nozzle bodies are respectively inserted into the nozzle opening according to the relationship of shape matching. The first nozzle body 220 is provided with a first eccentric through hole 210 , and the second nozzle body 200A is provided with a second eccen...

Embodiment 2

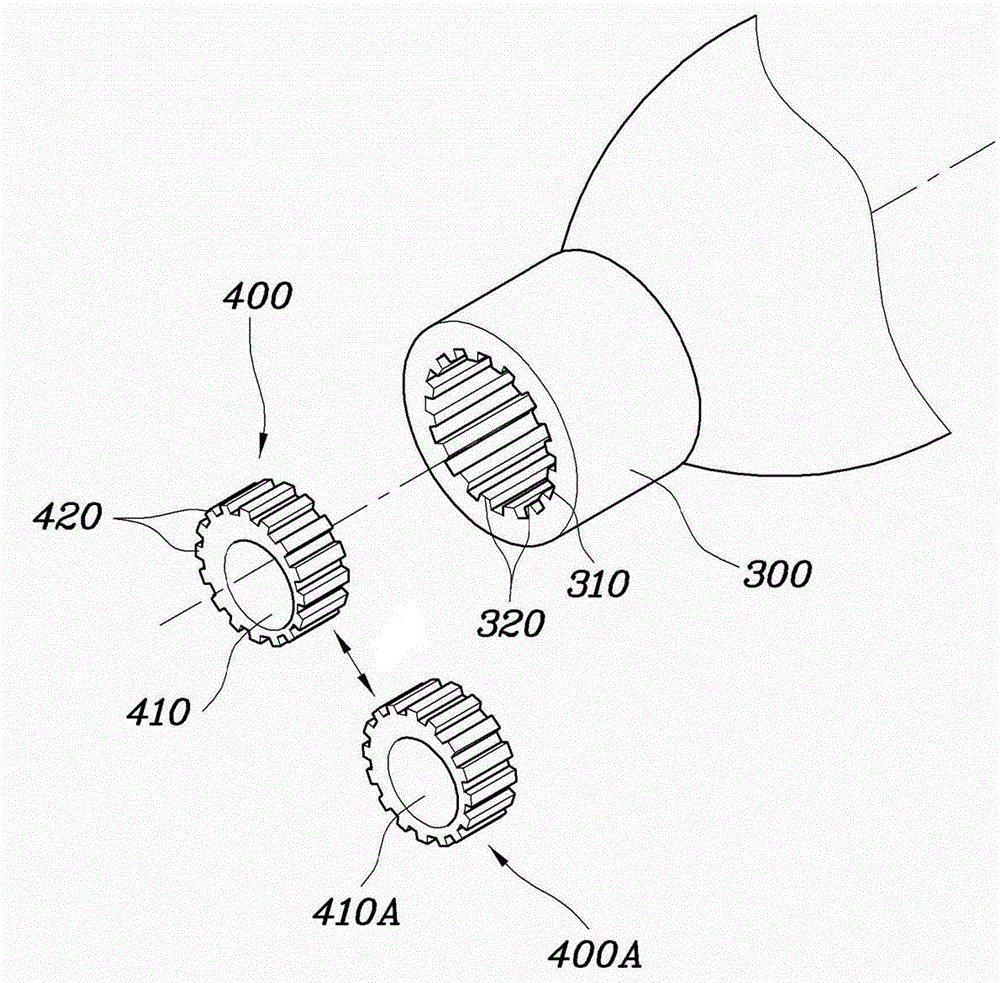

[0029] image 3 The reference numerals include: the inner wall of the nozzle mouth 310, the spline groove 320, the nozzle mouth 300, the first nozzle body 400, the first eccentric through hole 410, the second nozzle body 400A, the second nozzle body 200A, the second eccentric through hole 410A , Spline 420.

[0030] Such as image 3 As shown, the nozzle device of this embodiment includes a nozzle body, and the front end of the nozzle body is provided with a nozzle opening 300; the nozzle opening is a cylindrical structure with two ends open, and the cross section of the inner wall 310 of the nozzle opening is circular.

[0031] A first nozzle body 400 and a second nozzle body 400A are installed in the nozzle opening. The two nozzle bodies are respectively inserted into the nozzle opening according to the relationship of shape matching. The first nozzle body 400 is provided with a first eccentric through hole 410 , and the second nozzle body 400A is provided with a second ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com