A kind of graphite processing automatic tool change CNC machine tool

A CNC machine tool and automatic tool change technology, which is applied to stone processing equipment, stone processing tools, metal processing machinery parts, etc., can solve the problems of inconvenient tool replacement and achieve the effects of ensuring reliability, reducing wear and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

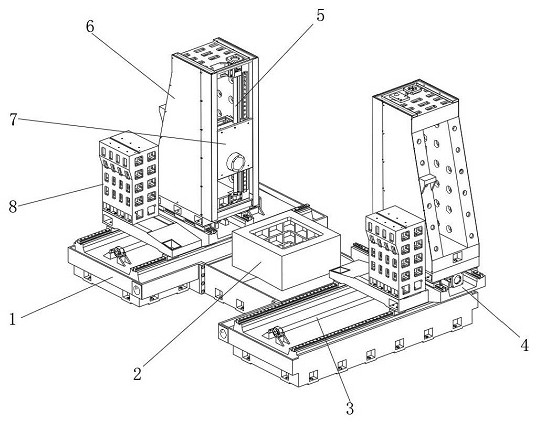

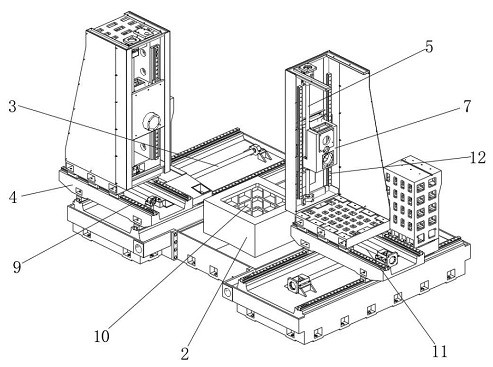

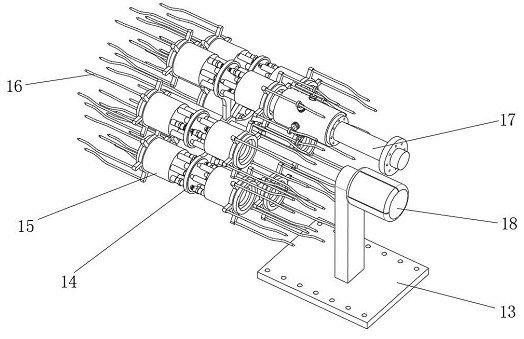

[0036] A kind of graphite processing automatic tool change CNC machine tool, such as figure 1 As shown, it includes an automatic tool changing mechanism and a multi-directional movable support frame. The automatic tool changing mechanism includes a mounting frame 13 and a motor 18. The motor 18 is fixed to the outer wall of one side of the mounting frame 13 by screws, and the output end of the motor 18 is connected by a drive There is a turret 14, the outer walls on both sides of the turret 14 are provided with housing seats 15 distributed evenly around the circumference, the housing seat 15 accommodates a tool 28, the tool 28 is matched with a tool fixing cylinder 19, and the outer wall of one side of the tool fixing cylinder 19 is provided. The mounting rod 17 is fixed with bolts, the circumferential outer wall of the tool fixing cylinder 19 is movably mounted with the fixing pin 25 through the first spring 33, and the fixing pin 25 is slidably connected with the cutting tool...

Embodiment 2

[0045] A kind of graphite processing automatic tool change CNC machine tool, such as figure 1 As shown, in order to facilitate the adjustment of the position of the accommodating seat 15; this embodiment makes the following improvements on the basis of Embodiment 1: the outer wall of one side of the accommodating seat 15 is integrally provided with a connecting head 37, and the outer wall of the connecting head 37 is rotatably connected with a Adjusting screw barrel 29, a threaded column 30 is fixed on the outer wall of one side of the turret 14, and the adjusting screw barrel 29 is adjustable on the outer wall of the threaded column 30 through threads; The distance between the tool fixing cylinder 19 and the turret 14 changes the moving distance when changing the tool, so as to meet different tool changing requirements and improve the practicability.

[0046] To improve reliability, such as Figure 8 As shown, a pressing block 38 is installed on the inner wall of one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com