Folding turnaround car

A revolving vehicle and folding technology, which is applied in the direction of trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of space occupation, inability to store large quantities, frequent transportation of parts and tooling, etc., to save space, facilitate hoisting operations, and facilitate stacking stored effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

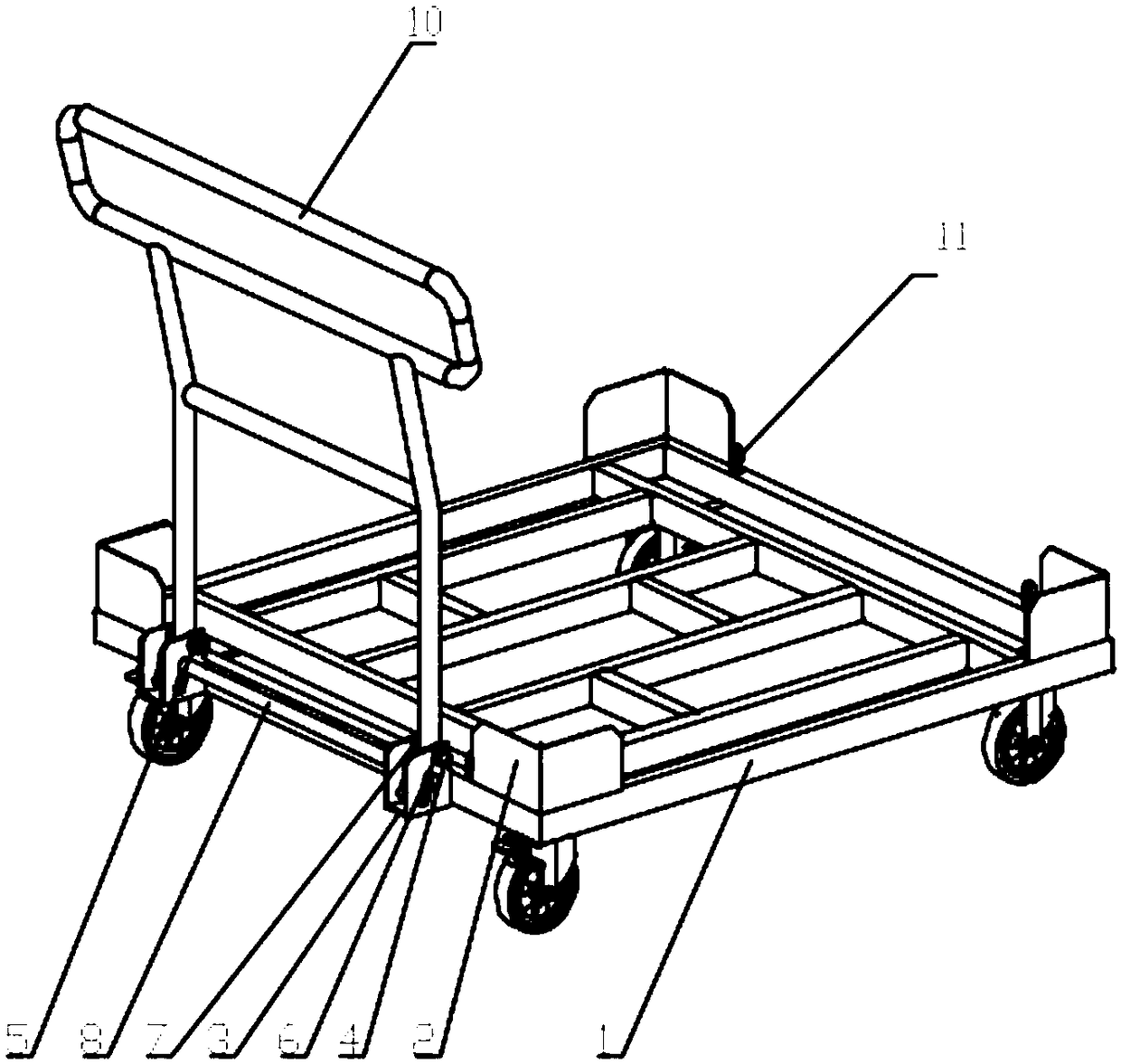

[0027] like figure 1 As shown, the foldable turnover vehicle of the present invention is mainly composed of a pallet 1, an armrest 10, an armrest support plate 3, a rotating mechanism, and a folding mechanism.

[0028] Introduce respectively below.

[0029] One: Tray 1

[0030] The pallet 1 is assembled by welding a plurality of rectangular tubes. The frame of the tray 1 is surrounded by four rectangular tubes, and several rectangular tubes are arranged in the middle of the enclosed area to form a supporting surface for lifting objects. The size of each rectangular tube can be 30*50MM.

[0031] The present invention does not limit the structure of the support surface. The structure of the tray 1 is not limited to the above-mentioned forms, and can be set according to actual needs, as long as it satisfies the stability of the objects being held.

[0032] Two: Rotating mechanism

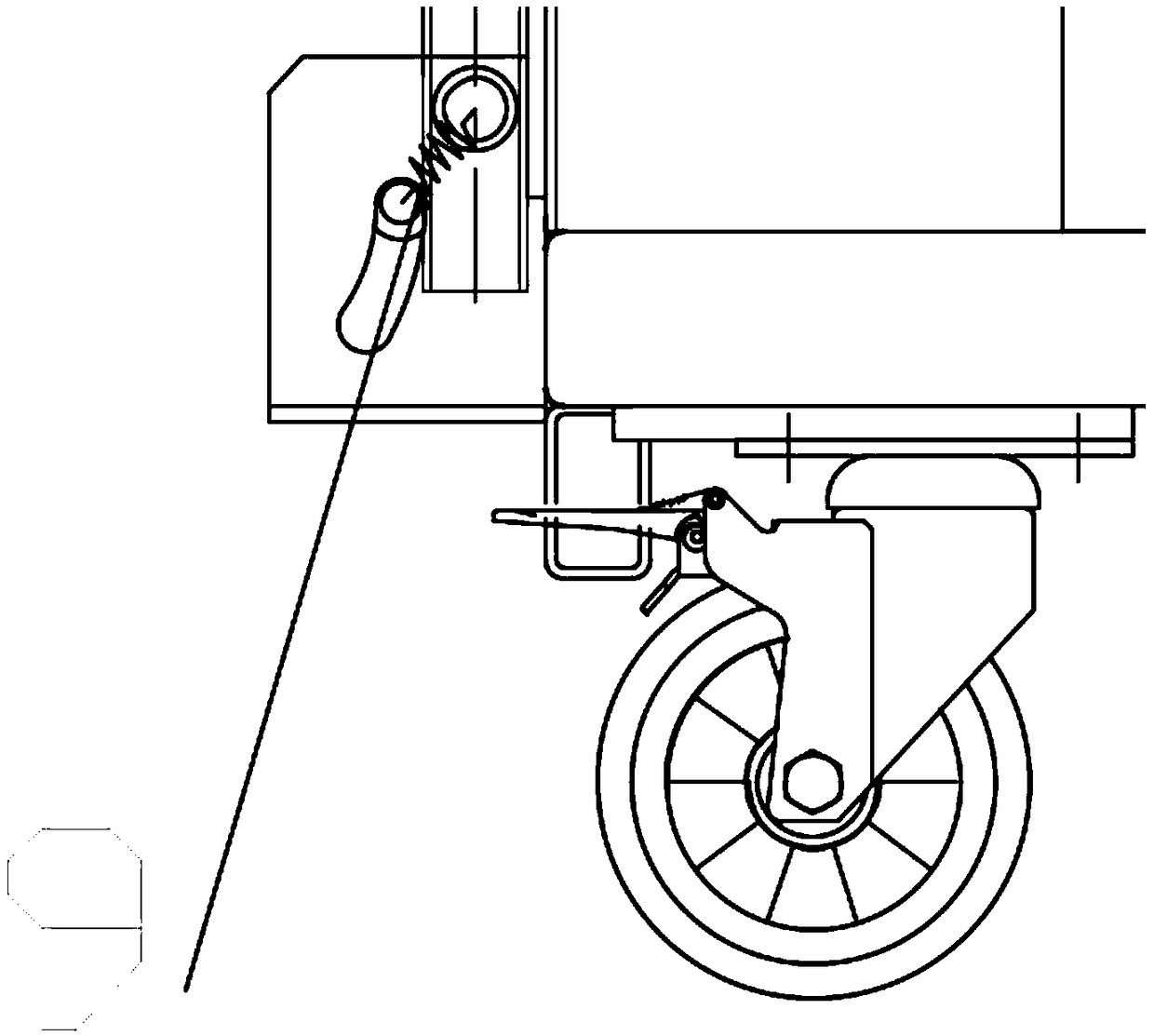

[0033] The turning mechanism includes two universal wheels and two directional wheels. Prefe...

specific Embodiment 2

[0047] In addition to the structure of Embodiment 1, a nylon washer 7 is also provided. The nylon washer 7 is sleeved on the screw 4 and located between the end of the support tube and the armrest support plate 3 . Nylon washer 7 is inner diameter 14MM, the nylon washer 7 of outer diameter 28MM.

specific Embodiment 3

[0048] In addition to the structure of Embodiment 1 or Embodiment 2, a washer 6 is provided, and the washer 6 is sleeved on the screw 4 and located between the lock nut 5 and the armrest support plate 3 . The washer 6 is a flat washer 6 with an inner diameter of 14 and an outer diameter of 28MM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com