Debugging and measuring device and method for debugging and measuring resistance of thermal head

A technology of debugging devices and thermal heads, applied in measuring devices, printing, instruments, etc., can solve problems such as difficult to meet production efficiency, difficult to apply, low fault tolerance rate, etc., to improve product quality and production efficiency, easy to operate, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

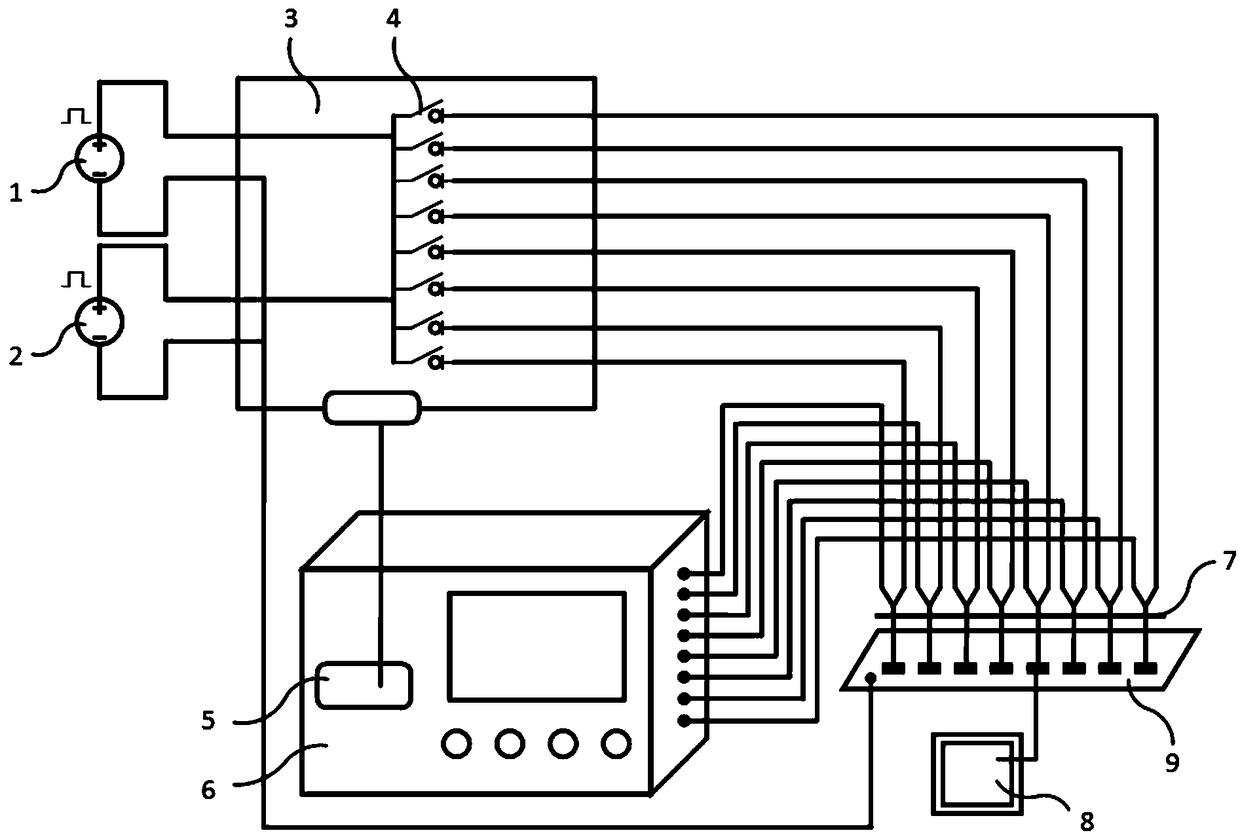

[0074] A testing device for heating resistors of thick film thermistors is proposed, including a high-voltage pulse power supply, a low-voltage pulse power supply, a controller, a resistance tester, a probe bank, and a temperature measurement module. Among them, the controller has multiple output interfaces, the relay group is set in the controller, the high-voltage pulse power supply is connected to the controller, the low-voltage pulse power supply is connected to the controller, the controller is connected to the resistance tester through a communication interface, and the resistance tester has multiple The probe row is composed of multiple probes, and each probe has two input ports, which are respectively connected to the multi-output interface of the controller and the multi-channel measurement interface of the resistance tester. The temperature measurement module and the thick film thermal Connected with the sensitive head, it is mainly used to measure the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com