Grinding material continuous supply method

A technology of abrasive and supplementary material, which is applied in the abrasive supply system and its supply field, can solve the problems of water jet operation failure, hardening and blockage at the bottom of the silo, and affecting the feeding function, etc., to simplify the system structure and system installation process , enhance adaptability, and save equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

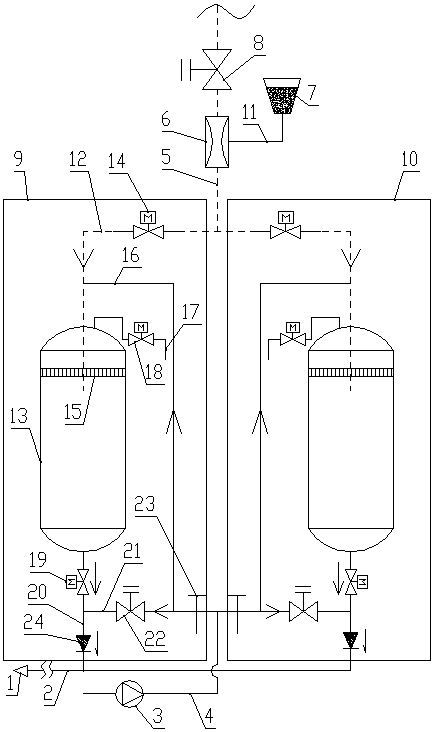

[0045] In the present invention, the fluid flow direction is taken as the downstream direction. Such as figure 1 As shown, the abrasive continuous supply method of the present invention is carried out by the coal mine underground abrasive continuous supply system, including a single tank operation mode and a double tank continuous operation mode;

[0046] The feeding mechanism includes working status and feeding status;

[0047] In the working state, the feeding valve 14 and the exhaust valve 18 of the feeding mechanism are closed, the water outlet valve 19, the flow regulating valve 22 and the high-pressure water inlet valve 23 are opened; the high-pressure water pump 3 is turned on, and the water in the external water source passes through the high-pressure water pump 3 After pressurization, it enters the high-pressure water inlet pipe 21 along the high-pressure water supply pipeline 4, and is divided into two paths of water after passing through the high-pressure water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com