Briquette polishing device for ceramic machining

A technology for ceramic processing and mud blanks, which is used in grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of inconvenient grinding, difficult cleaning, and flying dust, and achieves convenient cleaning and simple structure. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

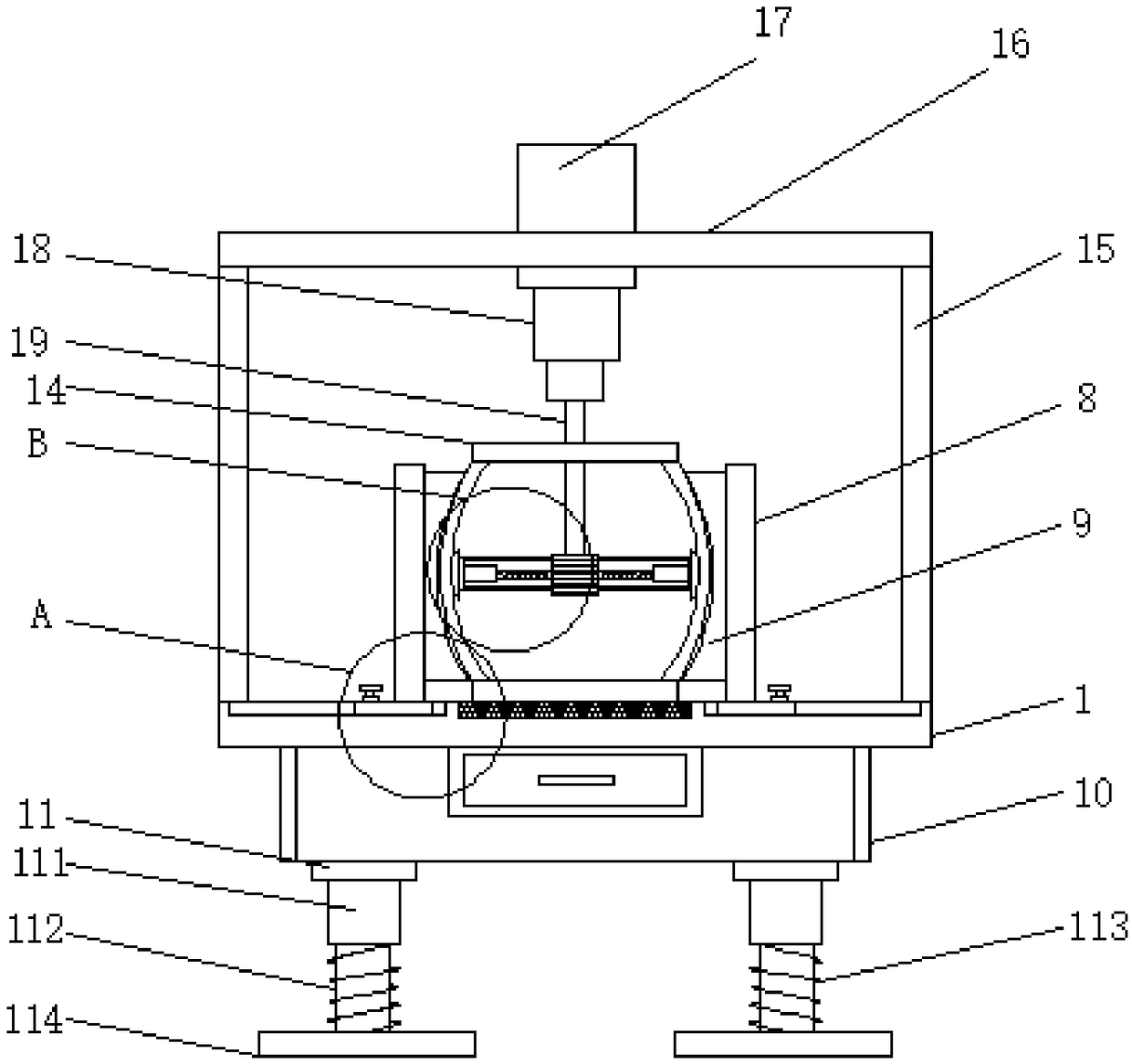

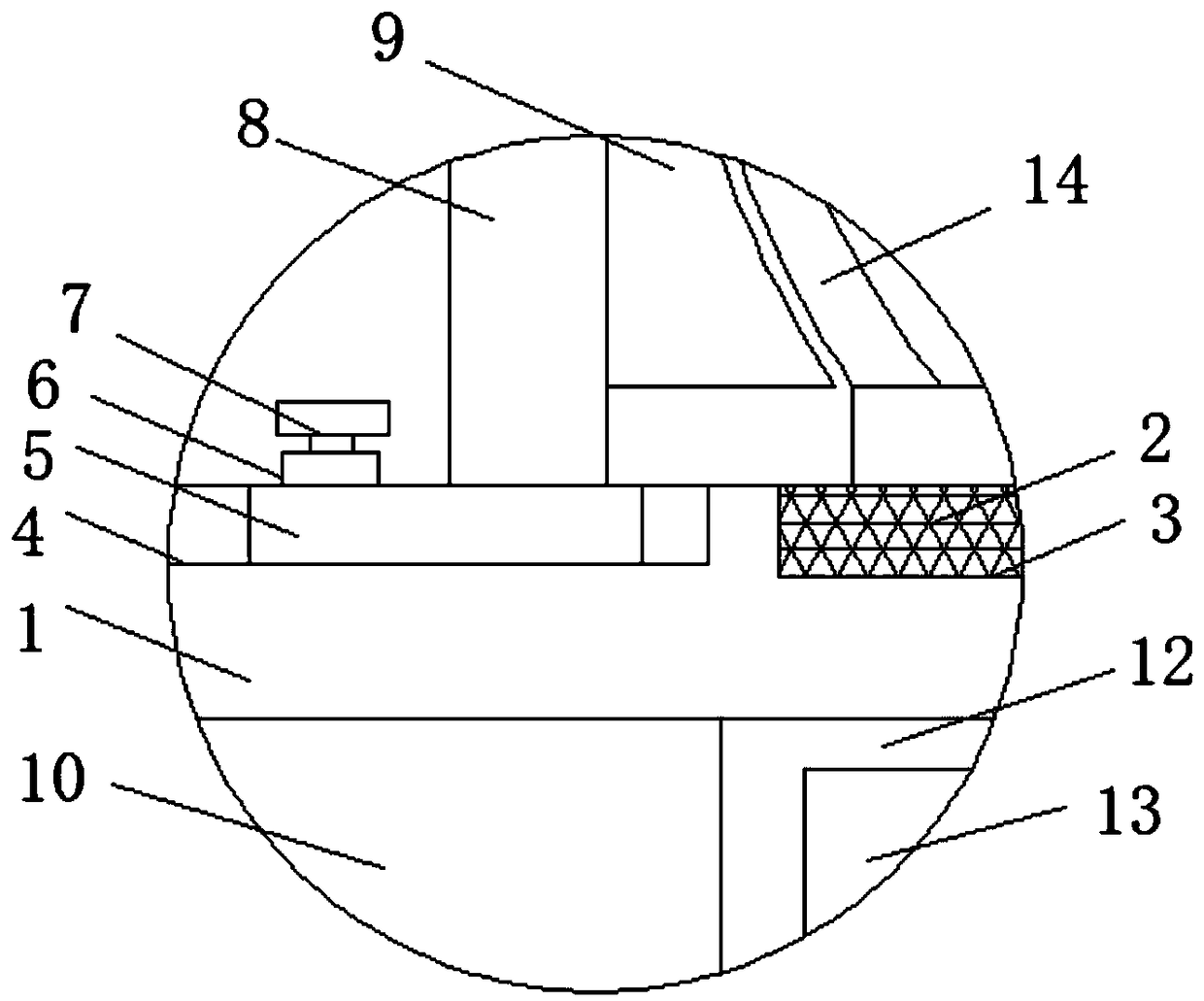

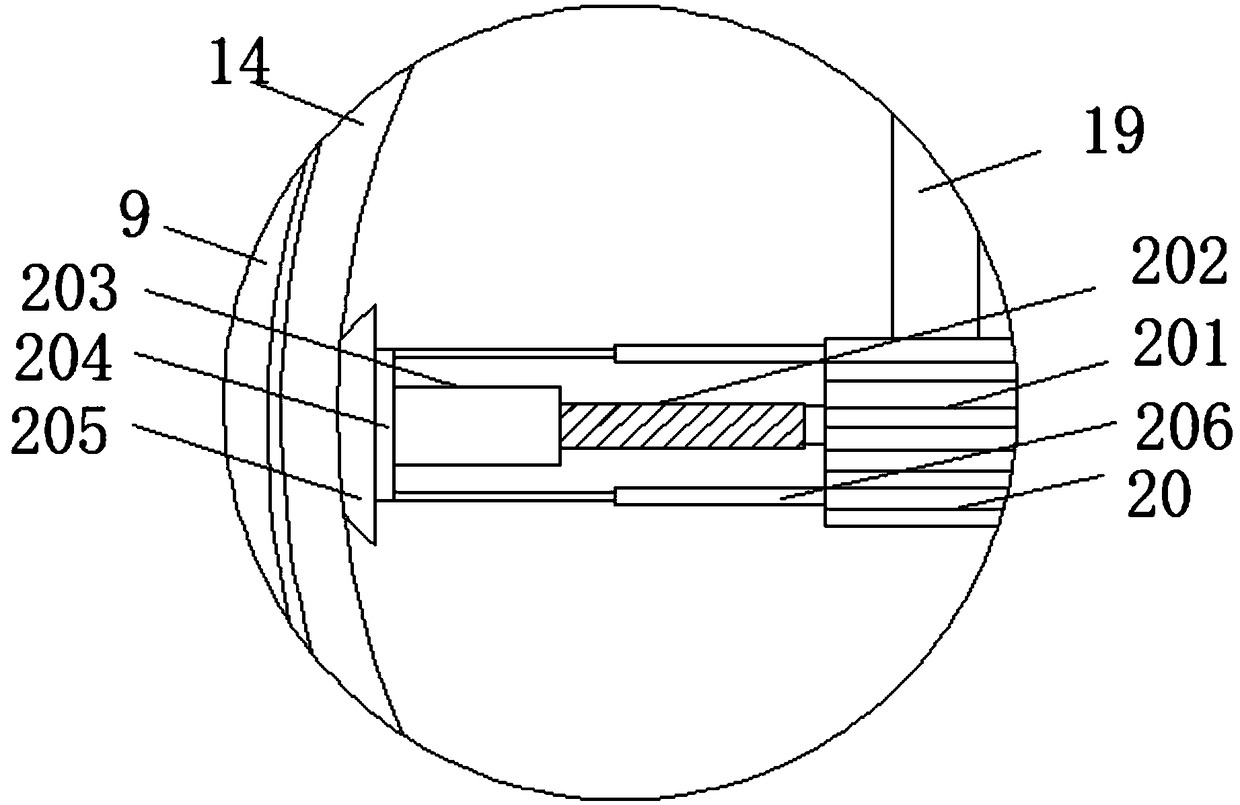

[0026] Such as Figure 1-3As shown, the present invention provides a technical solution: a mud body grinding device for ceramic processing, including a workbench 1, the middle part of the top of the workbench 1 is provided with a collection tank 2, and the inside of the collection tank 2 is fixedly connected with a partition net 3, Both sides of the top of the workbench 1 are provided with a chute 4, the inside of the chute 4 is movably connected with a slider 5, and one side of the top of the slider 5 is fixedly connected with a limit sleeve 6, and the internal thread of the limit sleeve 6 is connected with a second A threaded rod 7, the other side of the limit sleeve 6 top is fixedly connected with a fixed plate 8, and one side of the fixed plate 8 is fixedly connected with a polishing sheet 9, the shape of the polishing sheet 9 is arc-shaped, and the shape of the polishing sheet 9 is the same as The shape of the outside of mud base body 14 is adapted, and this grinding piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com