Solid organic waste treatment and separation system based on supercritical water oxidation technology

A technology for supercritical water oxidation and organic waste, applied in the removal of solid waste, etc., can solve problems such as blockage, avoid salt deposition, enhance fluid turbulence intensity, and improve continuous transmission and distribution capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

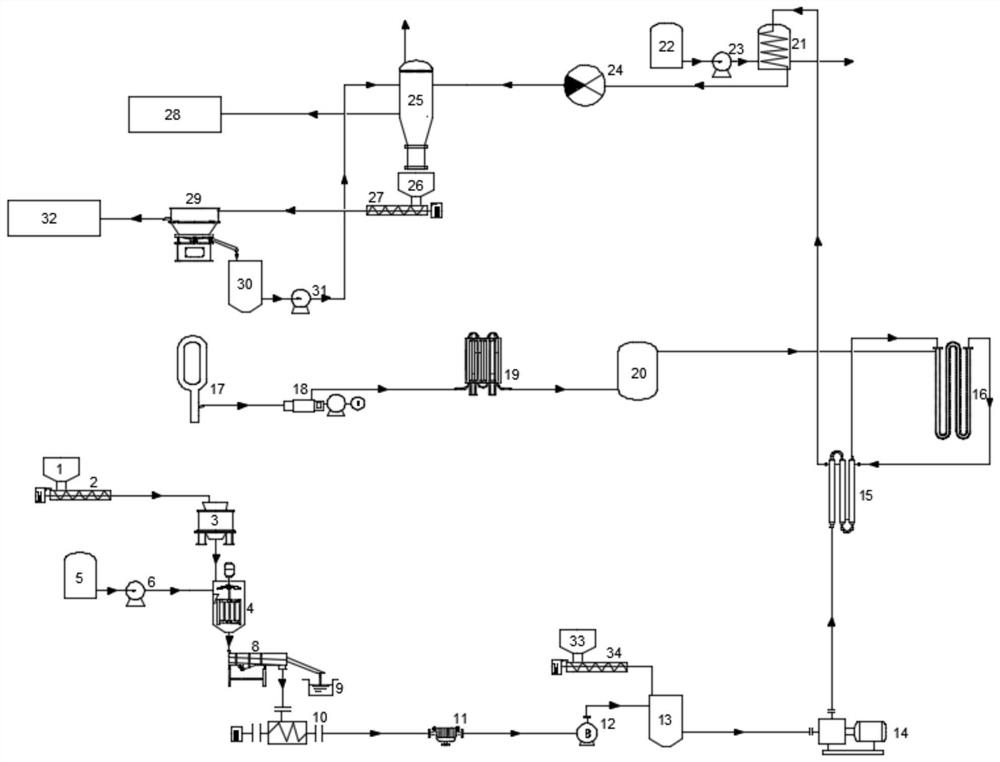

[0027] see figure 1 , the solid-containing organic waste treatment and separation system based on supercritical water oxidation technology in the present invention includes a solid-containing waste pretreatment module, a solid-containing waste preheating module, an oxidant supply module, a supercritical water oxidation module, and subsequent product cooling and pressure reduction Module, follow-up product online separation module.

[0028] In this system, each device is connected as follows:

[0029] The outlet of the solid waste silo 1 is connected to the inlet of the first screw conveyor 2, the outlet of the first screw conveyor 2 is connected to the inlet of the crusher 3, the outlet of the crusher 3 is connected to the material inlet of the solid waste preparation tank 4, and the softened water tank 5 The outlet is connected to the inlet of the softened water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com