Total mixed ration additive for dairy cows

A fully mixed and additive technology, applied in food processing, additional food elements, food preservation, etc., can solve the problems of mildewing of fully mixed rations and the impact of dairy cattle production performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

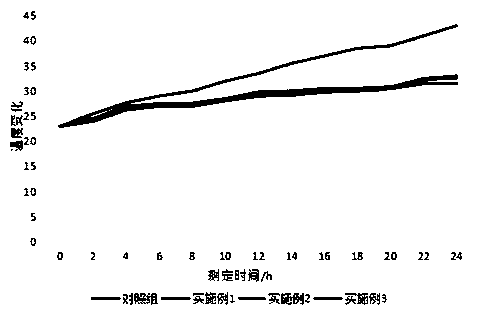

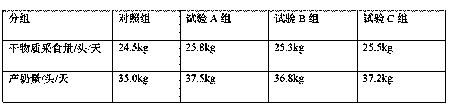

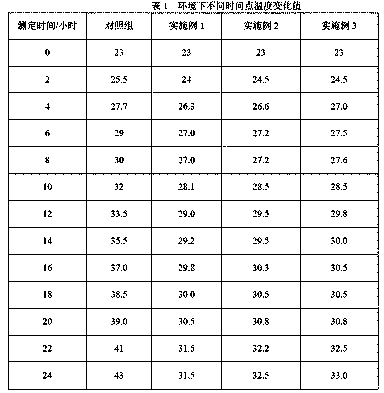

[0018] Example 1 A kind of dairy cow total mixed ration additive

[0019] A kind of dairy cow full mixed diet additive, according to the weight and the number of parts of its raw materials: 50kg of molasses, 26kg of xylose, 4kg of complex probiotic metabolites, 12kg of propionic acid, and 8kg of ammonium propionate; the complex probiotic metabolites It is obtained by preparing yeast metabolites and plantarum metabolites according to the patent application number CN201410265032.4, and compounding them according to the mass ratio of 1:1;

[0020] It is prepared by the following method: fully mix 8kg ammonium propionate, 8kg molasses, 26kg xylose, 12kg propionic acid, and 4kg compound probiotic metabolites of solid powder to obtain mixture A; then add it to 42kg molasses, and Stir while adding; weigh and fill, and store in a cool place at room temperature.

[0021] How to use: Spray 2.0~4.0% of the fresh sample weight of the TMR ration directly into the total mixed ration of dai...

Embodiment 2

[0022] Example 2 A kind of dairy cow total mixed ration additive

[0023] A kind of dairy cow full mixed diet additive, according to the weight and the number of parts of its raw materials: 60kg of molasses, 20kg of xylose, 2kg of compound probiotic metabolites, 10kg of propionic acid, and 8kg of ammonium propionate; the compound probiotic metabolites It is obtained by preparing yeast metabolites and plantarum metabolites according to the patent application number CN201410265032.4, and compounding them according to the mass ratio of 1:1;

[0024] It is prepared by the following method: fully mix 8kg ammonium propionate, 8kg molasses, 20kg xylose, 10kg propionic acid, and 2kg compound probiotic metabolites of solid powder to obtain mixture A; then add it to 52kg molasses, and Stir while adding; weigh and fill, and store in a cool place at room temperature.

[0025] How to use: Spray 2.0~4.0% of the fresh sample weight of the TMR ration directly into the total mixed ration of d...

Embodiment 3

[0026] Example 3 A kind of dairy cow total mixed ration additive

[0027] A kind of dairy cow full mixed diet additive, according to the weight and the number of parts of its raw materials: 55kg of molasses; 30kg of xylose, 2kg of compound probiotic metabolites, 8kg of propionic acid, 5kg of ammonium propionate; the compound probiotic metabolites It is obtained by preparing yeast metabolites and plantarum metabolites according to the patent application number CN201410265032.4, and compounding them according to the mass ratio of 1:1;

[0028] It is prepared by the following method: fully mix 5kg ammonium propionate, 5kg molasses, 30kg xylose, 8kg propionic acid, and 2kg compound probiotic metabolites of solid powder to obtain mixture A; then add it to 50kg molasses, and Stir while adding; weigh and fill, and store in a cool place at room temperature.

[0029] How to use: Spray 2.0~4.0% of the fresh sample weight of the TMR ration directly into the total mixed ration of dairy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com