Pretreatment method for determination of heavy metals in pig manure

A technology for heavy metals and pig manure, which is applied to measurement devices, preparation and sampling of samples for testing, etc., can solve the problems of water environment pollution, only production and use of manure, and destruction of farmland ecological environment. The effect of temperature optimization, reducing inspection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A pretreatment method for the determination of heavy metals in pig manure, comprising the steps of:

[0017] (1) Take a pig manure sample and place it in an oven to dry at 60°C to constant weight, crush it with a powder sample machine and pass it through an 80-mesh sieve to obtain pig manure powder;

[0018] (2) Take 0.2g of pig manure powder and place it in the digestion tube, then add the digestion liquid into the digestion tube according to the solid-to-liquid ratio of 1:30, shake well, and cover the digestion tube;

[0019] The digestion solution is composed of nitric acid and hydrochloric acid according to a volume ratio of 1:6;

[0020] (3) Put the digestion tube into the graphite furnace, digest for 60 minutes, and set the digestion temperature to 120°C;

[0021] (4) After the digestion is completed, cool down to obtain the sample pretreatment solution, which is subjected to twice constant volume of the sample pretreatment solution, and then detected by ICP-MS; ...

Embodiment 2

[0024] experimental method:

[0025] (1) Take the pig manure sample and place it in an oven for drying at 60°C, crush it with a powder sample machine and pass it through an 80-mesh sieve to obtain pig manure powder;

[0026] (2) Dry the pig manure powder at 60°C to constant weight and weigh 0.2g of the pig manure powder;

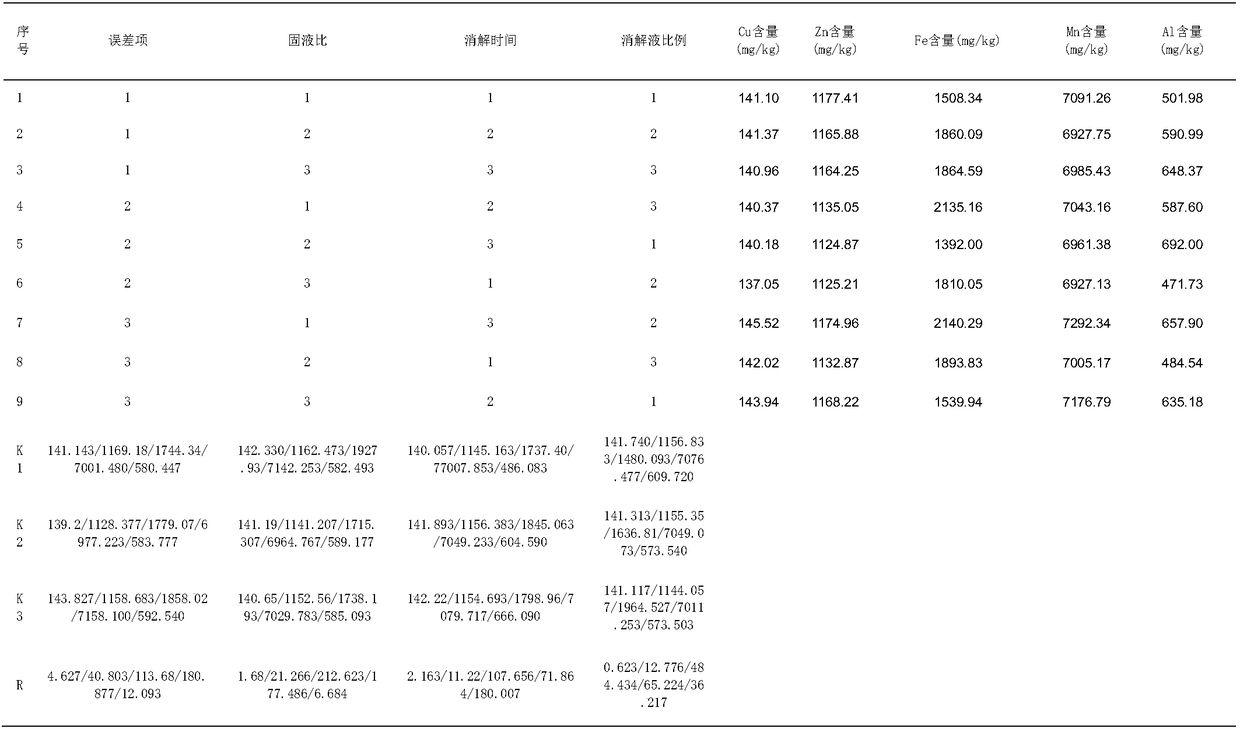

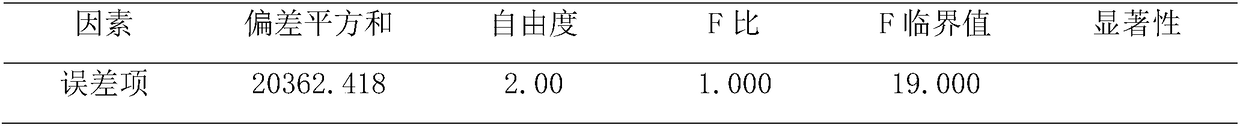

[0027] (3) Orthogonal experimental design of digestion test:

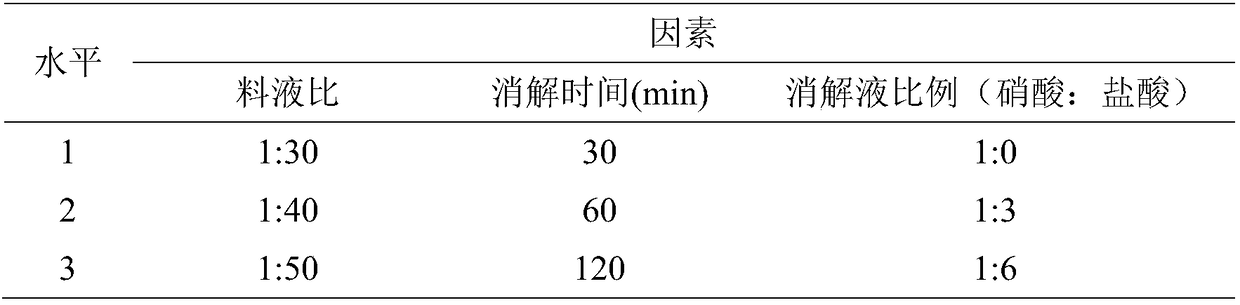

[0028] Three factors were selected: solid-liquid ratio, digestion time (min), and volume ratio of digestion solution (nitric acid: hydrochloric acid), each factor was set at three levels (Table 1), and L9 (33) orthogonal design was adopted. According to the orthogonal experimental design, 9 experiments were performed, each experiment was repeated 3 times, and a total of 27 measurements were made. At the same time, three blank control experiments were set up.

[0029] Table 1 3-factor horizontal orthogonal design table

[0030]

[0031] (4) Set the digestion temperature to 120°C. Digest eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com