High calorific value environment-friendly alcohol-based fuel, preparation method and application thereof

A technology of alcohol-based fuel with high calorific value, applied in fuel, fuel additive, liquid carbon-containing fuel, etc., can solve the problems of poor thermal efficiency, poor economy, splashing, etc., and achieve the effect of not easy loss, low cost, and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

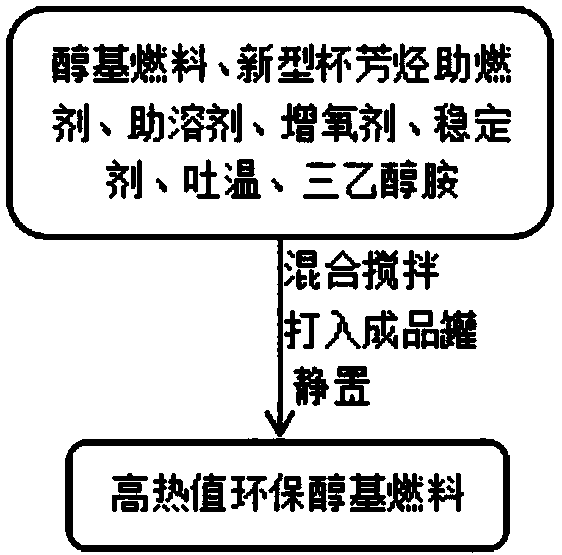

Method used

Image

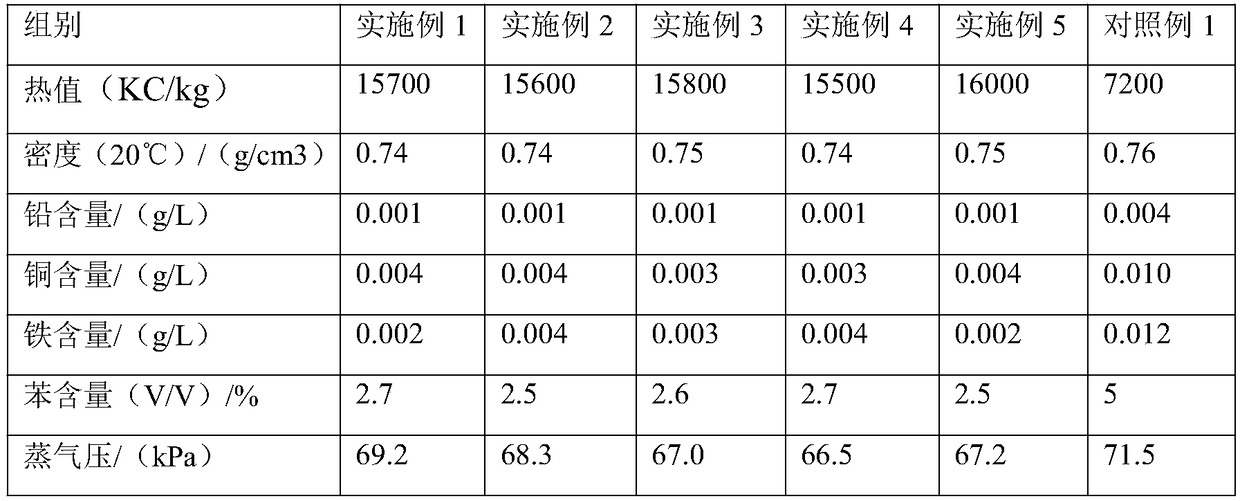

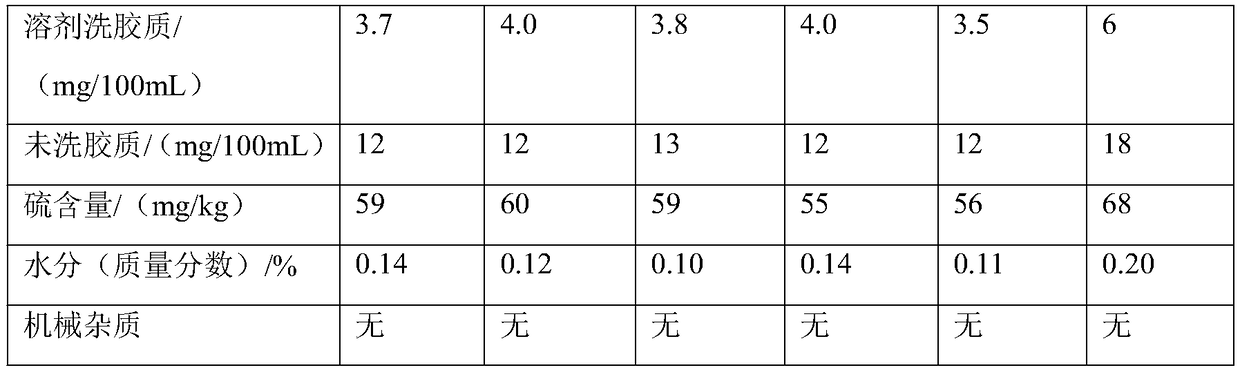

Examples

Embodiment 1

[0045] Embodiment 1 Preparation of high calorific value environment-friendly alcohol-based fuel

[0046] Raw material composition:

[0047] 40 parts of alcohol-based fuel (6% methyl ether, 16% ethyl acetate, 45% ethanol, 7.5% acetone, 10% isopropanol, 4.5% methyl ethyl ketone, 8% butanol and 3% higher fatty alcohol);

[0048] 10 parts of novel calixarene combustion accelerant;

[0049] 0.5 parts of urethane;

[0050] 2 parts of methylal;

[0051] Nonylphenol polyoxyethylene ether NP-41 parts;

[0052] Tween 0.1 part;

[0053] 1 part of triethanolamine.

[0054] The novel calixarene combustion enhancer is prepared according to the following method: add p-methoxyphenol, paraformaldehyde, sodium hydroxide solution, naphthalene and Solvent xylene, protected by nitrogen, heated to reflux with an oil bath, and became a homogeneous solution after 30min. Within 1h, a yellow precipitate was precipitated. Refluxed for 4h, cooled to room temperature, filtered, and the filter cake w...

Embodiment 2

[0057] Embodiment 2 Preparation of high calorific value environment-friendly alcohol-based fuel

[0058] Raw material composition:

[0059] 70 parts of alcohol-based fuel (5.5% methyl ether, 20% ethyl acetate, 60% methanol, 4.5% acetone, 3% isopropanol, 1.5% methyl ethyl ketone, 2.5% butanol and 3% higher fatty alcohol);

[0060] 20 parts of novel calixarene combustion accelerant;

[0061] 4.5 parts of 2-hydroxypropane 1,2,3-tricarboxylic acid;

[0062] 7 parts of diethyl carbonate;

[0063] Octylphenol polyoxyethylene ether OP-105 parts;

[0064] Tween 0.5 part;

[0065] 2 parts of triethanolamine.

[0066] The novel calixarene combustion enhancer is prepared according to the following method: add p-methoxyphenol, paraformaldehyde, sodium hydroxide solution, naphthalene and Solvent xylene, protected by nitrogen, heated to reflux with an oil bath, and became a homogeneous solution after 30min. Within 1h, a yellow precipitate was precipitated. Refluxed for 4h, cooled to roo...

Embodiment 3

[0069] Embodiment 3 Preparation of high calorific value environment-friendly alcohol-based fuel

[0070] Raw material composition:

[0071] 50 parts of alcohol-based fuel (6% methyl ether, 15% methyl formate, 50% methanol, 5% acetone, 8% isopropanol, 4% methyl ethyl ketone, 7% butanol and 5% higher fatty alcohol);

[0072] 12 parts of new-type calixarene combustion accelerant;

[0073] 1 part iso-octanol;

[0074] 4 parts of methyl isobutyl ether;

[0075] Octylphenol polyoxyethylene ether OP-62 parts;

[0076] Tween 0.2 parts;

[0077] 1.2 parts of triethanolamine.

[0078] The novel calixarene combustion enhancer is prepared according to the following method: add p-methoxyphenol, paraformaldehyde, sodium hydroxide solution, naphthalene and Solvent xylene, protected by nitrogen, heated to reflux with an oil bath, and became a homogeneous solution after 30min. Within 1h, a yellow precipitate was precipitated. Refluxed for 4h, cooled to room temperature, filtered, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com